Bulleyaconitine A lipidosome freeze-dried powder injection and preparation method thereof

A technology of freeze-dried powder injection and clathrate, which is applied in the field of liposome freeze-dried powder injection containing clathrin and its preparation, which can solve the problem of unmentioned skin irritation and the stability of liposomes. It can reduce skin irritation, prolong drug action time, and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

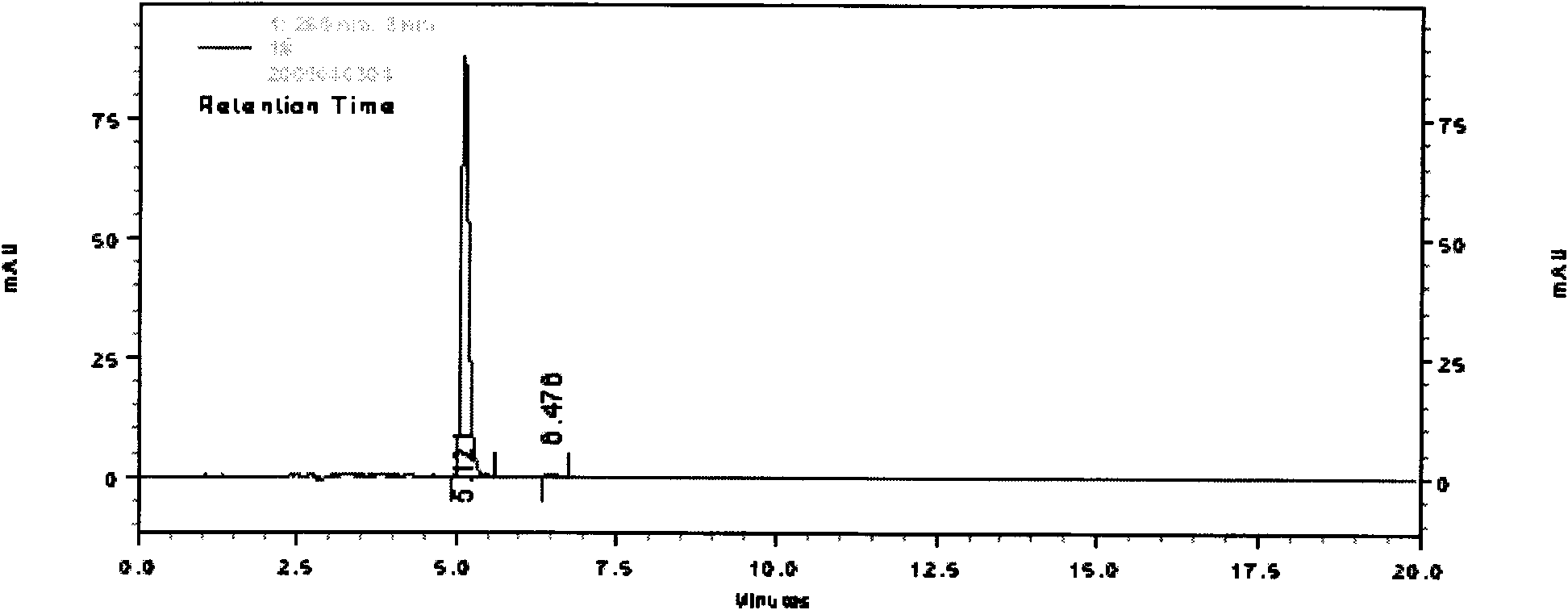

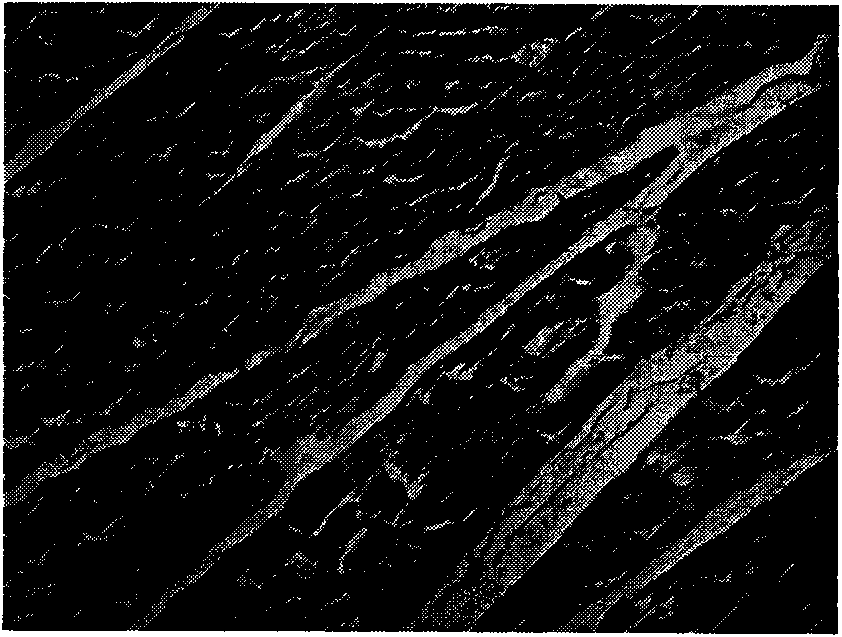

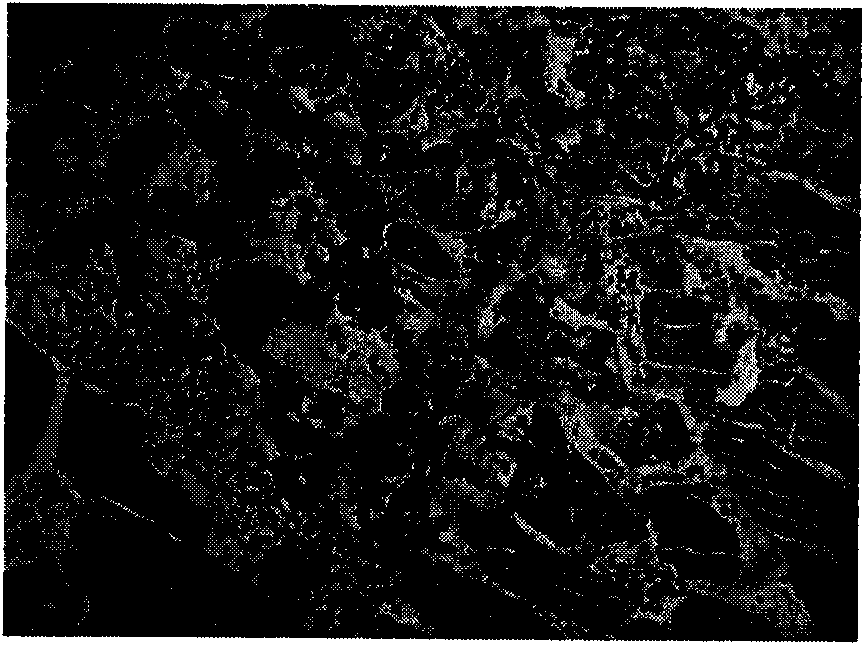

Image

Examples

Embodiment 1

[0055] Prescription (100 formulation units):

[0056] Phospholipid S100 2g

[0057] Cholesterol 0.3g

[0058] Aconitine 40mg

[0059] Ethanol 90ml

[0060] 0.15mol / L citrate buffer solution of pH4.0 100ml

[0061] 0.10mol / L sodium carbonate aqueous solution several ml

[0062] Mannitol 10g

[0063] Preparation method: Take the prescribed amount of phospholipid S100 and cholesterol, dissolve in an appropriate amount of ethanol, remove the solvent by rotary evaporation under reduced pressure at 48°C, and after forming a dry film, add citrate buffer solution with pH 4.0, shake to wash the film completely Take off, obtain the blank liposome of large particle size. High-speed shearing with a high-shear divergent emulsifier for 5 minutes, and high-pressure emulsification at 800 bar for 10 times to obtain blank liposomes with small particle sizes. Use a carbonate solution to adjust the pH of the external phase to 7-8 to obtain sample 1; weigh the prescribed amount of aconitin,...

Embodiment 2

[0066] Prescription (100 formulation units):

[0067] Phospholipid S100 4.8g

[0068] Cholesterol 0.6g

[0069] Aconitine 80mg

[0070] Methanol 50ml

[0071] 0.15mol / L citrate buffer solution of pH4.0 100ml

[0072] 0.10mol / L sodium carbonate aqueous solution several ml

[0073] Sucrose 4.8g

[0074] Preparation method: Take the prescribed amount of phospholipid S100 and cholesterol, dissolve in an appropriate amount of methanol, and remove the solvent by rotary evaporation at 40°C under reduced pressure. After forming a dry film, add citrate buffer solution with pH 4.0, and shake to wash the film completely. Take off, obtain the blank liposome of large particle size. High-speed shearing with a high-shear divergent emulsifier for 10 minutes, and high-pressure emulsification at 700 bar for 20 times to obtain blank liposomes with small particle sizes. Use a carbonate solution to adjust the pH of the external phase to 7-8 to obtain sample 1; weigh the prescribed amount of...

Embodiment 3

[0077] Prescription (100 formulation units):

[0078] Phospholipid S100 20mg

[0079] Cholesterol 20mg

[0080] Aconitine 20mg

[0081] Chloroform 30ml

[0082] 0.15mol / L citrate buffer solution of pH4.0 100ml

[0083] 0.10mol / L sodium carbonate aqueous solution several ml

[0084] Glucose 7g

[0085] Preparation method: Take the prescribed amount of phospholipid S100 and cholesterol, dissolve it in an appropriate amount of chloroform, remove the solvent by rotary evaporation under reduced pressure at 48°C, and after forming a dry film, add citrate buffer solution with pH 4.0, shake to wash the film completely Take off, obtain the blank liposome of large particle size. High-speed shearing with a high-shear divergent emulsifier for 10 minutes, and high-pressure emulsification at 700 bar for 10 times to obtain blank liposomes with a small particle size. Use a carbonate solution to adjust the pH of the external phase to 7-8 to obtain sample 1; weigh the prescribed amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com