Analytical method of phenolic compounds in coal direct liquefaction oil

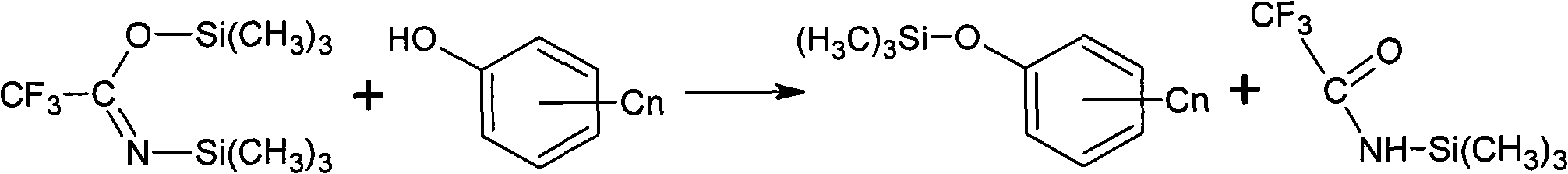

A technology of phenolic compounds and coal liquefied oil, which is applied to the analysis of materials, material separation, and measuring devices, etc., can solve the problems of overlapping chromatographic peaks, inability to effectively separate, low volatility, etc., to expand the detection range, improve the separation effect, The effect of promoting a complete response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

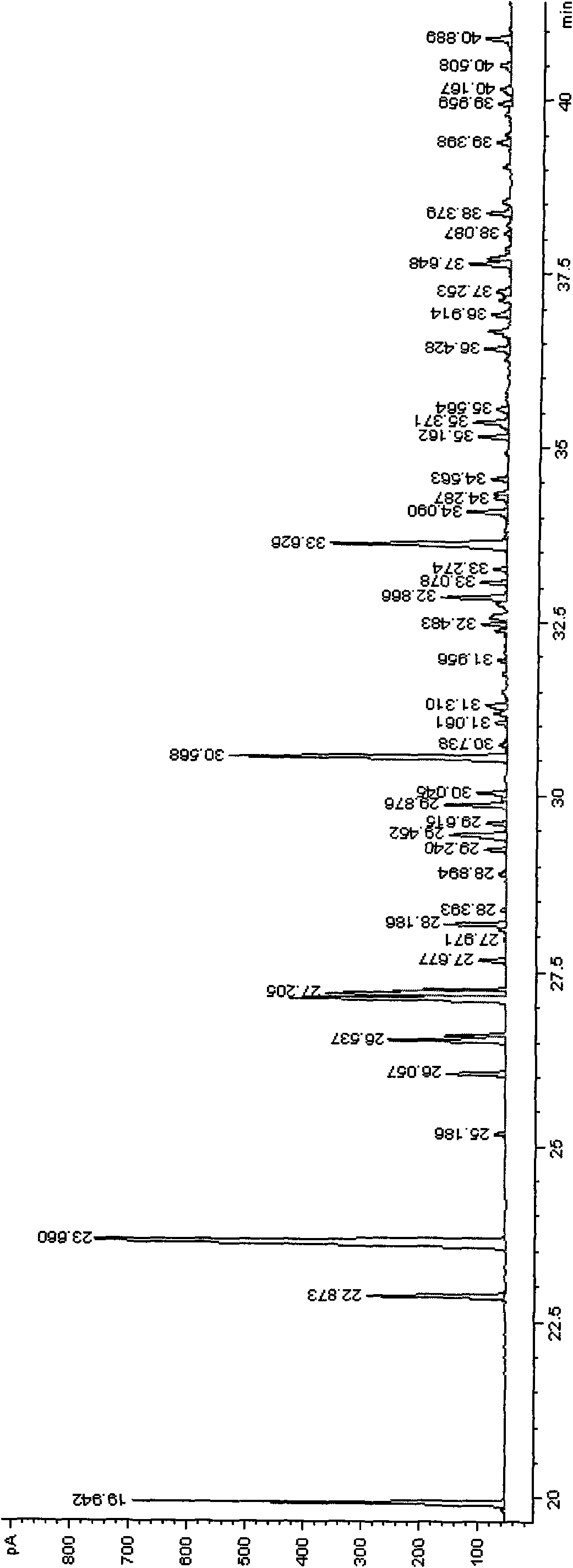

[0034] Weigh 2 mg of 27 standard monomeric phenolic compound samples (see Table 1 below for details), dissolve them in dichloromethane, and add 12ul N, O-bis(trimethylsilyl) corresponding to each standard monomeric phenol - 2,2,2-trifluoroacetamide (BTSFA) silicon etherification reagent and 20ul pyridine, after the complete reaction, mix the standard phenol with a 25ml volumetric flask for quantification, and place it at room temperature for 12 hours before use. Take mixed phenol standard samples for chromatography-mass spectrometry and gas chromatography analysis to determine the standard retention time of various monomeric phenols. At the same time, take 5ml, 10ml, 15ml, and 20ml standard phenol solutions to establish a four-level calibration table using external standards The percentage method was used for quantitative analysis. Table 1 shows the retention time of the monomeric phenols and the retention time of the derivatives after silicon etherification.

[0035] Table 1...

Embodiment 2

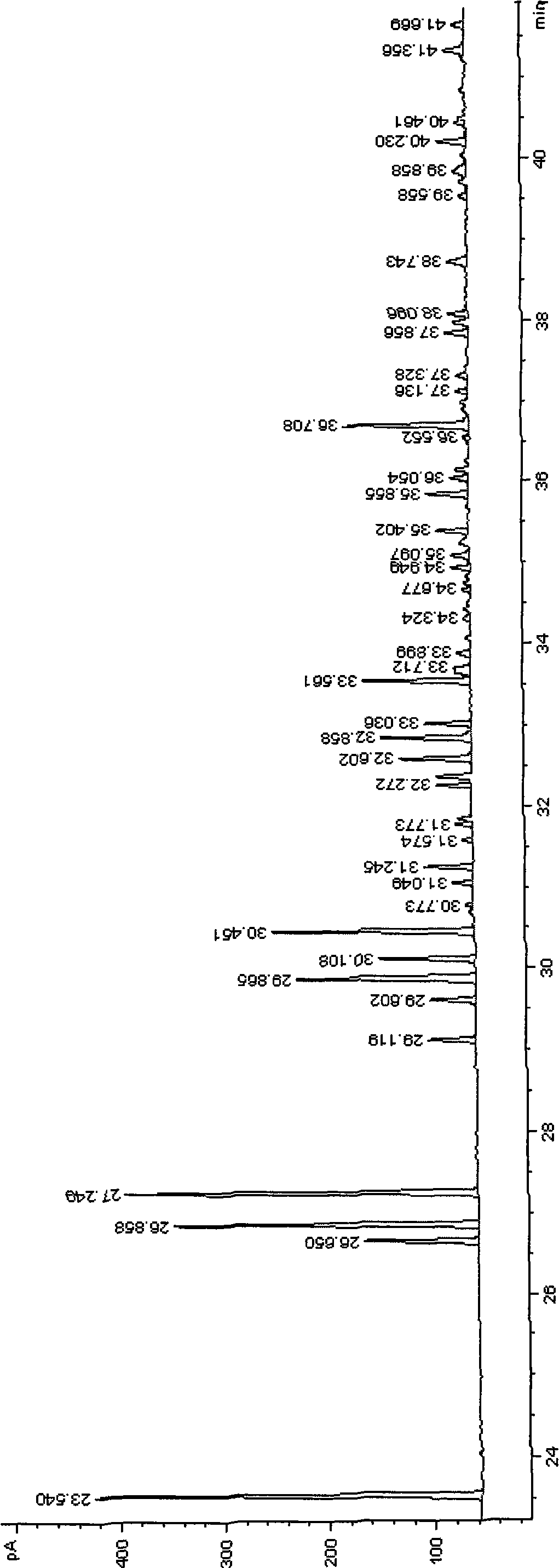

[0039] Same as the chromatographic condition of embodiment 1

[0040] Weigh 100g of coal liquefied oil, add 25ml of NaOH (10%) solution, fully shake in the separatory funnel for 5 minutes, separate the lower layer of water phase after standing for stratification, and repeatedly extract the upper layer of organic layer with NaOH (10%) solution three times, After combining four lower aqueous phases, wash with H 2 SO 4 (10M) solution neutralizes the lower alkali solution and adjusts PH=1, shakes for 5 minutes, puts the layers in a separating funnel for 10 minutes, collects the upper organic layer and then adds Na 2 SO 4 After dehydration, the solution can be enriched to obtain phenolic compounds in coal liquefied oil under the condition of 40°C water bath. Take 1.0 mg of the enriched phenolic compound, add 6.0 ul of BTSFA, and add 6 ul of pyridine, use dichloromethane as solvent, prepare 5 ml of solution in a 5 ml volumetric flask, place it at room temperature for 12 hours, an...

Embodiment 3

[0048] When diphenylphosphoryl chloride (DPPC) is selected as the derivatization reagent, N, O-bis(trimethylsilyl)-2,2,2-trifluoroacetamide (BTSFA) is selected as the derivatization reagent in other conditions Conditions during the time, still can obtain the result identical with example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com