Preparation method for LiTiO/C compound electrode material

A composite electrode and compound technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve problems such as poor electronic conductivity, and achieve the effects of less reaction energy consumption, improved rate performance, and regular morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

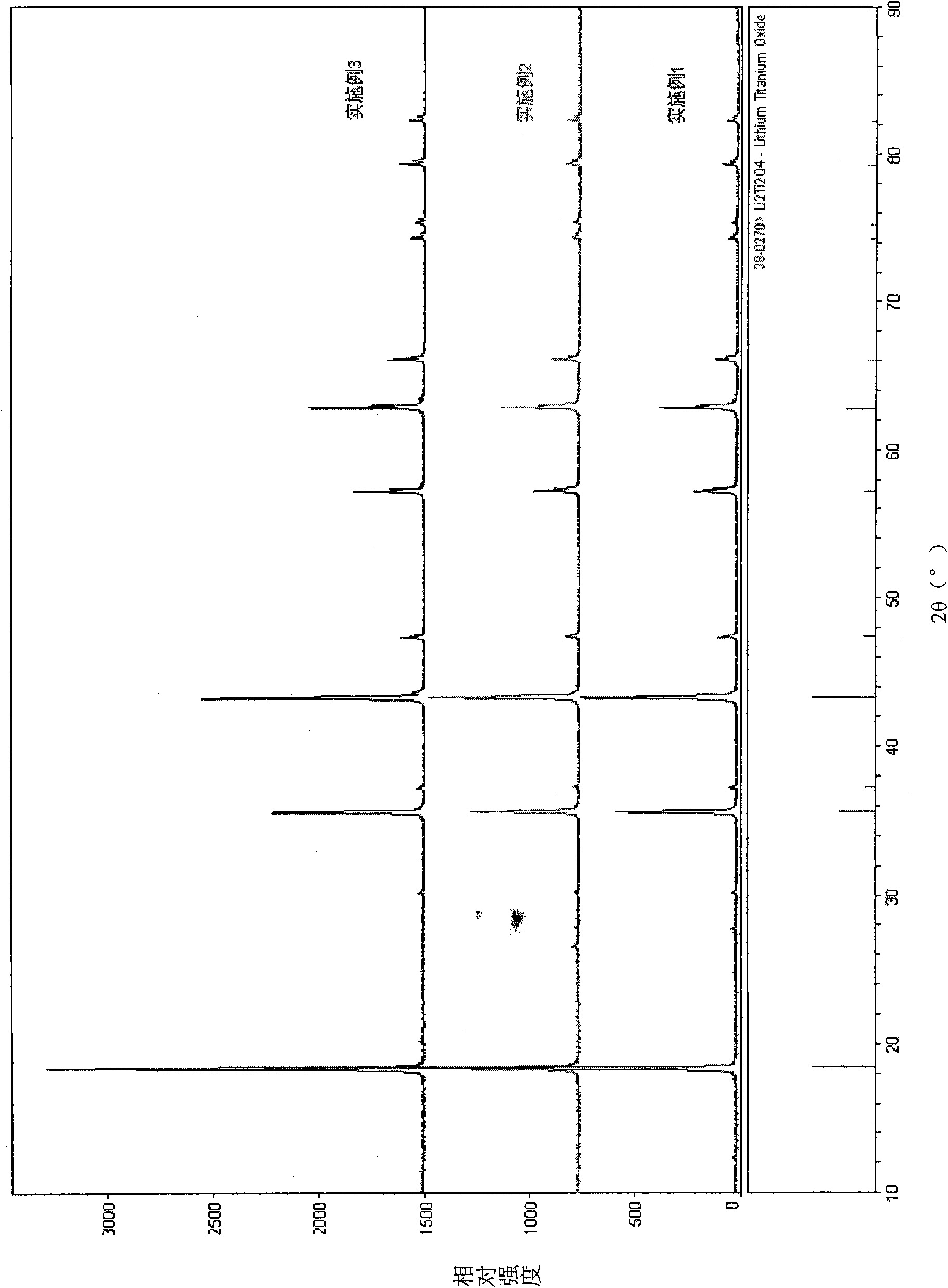

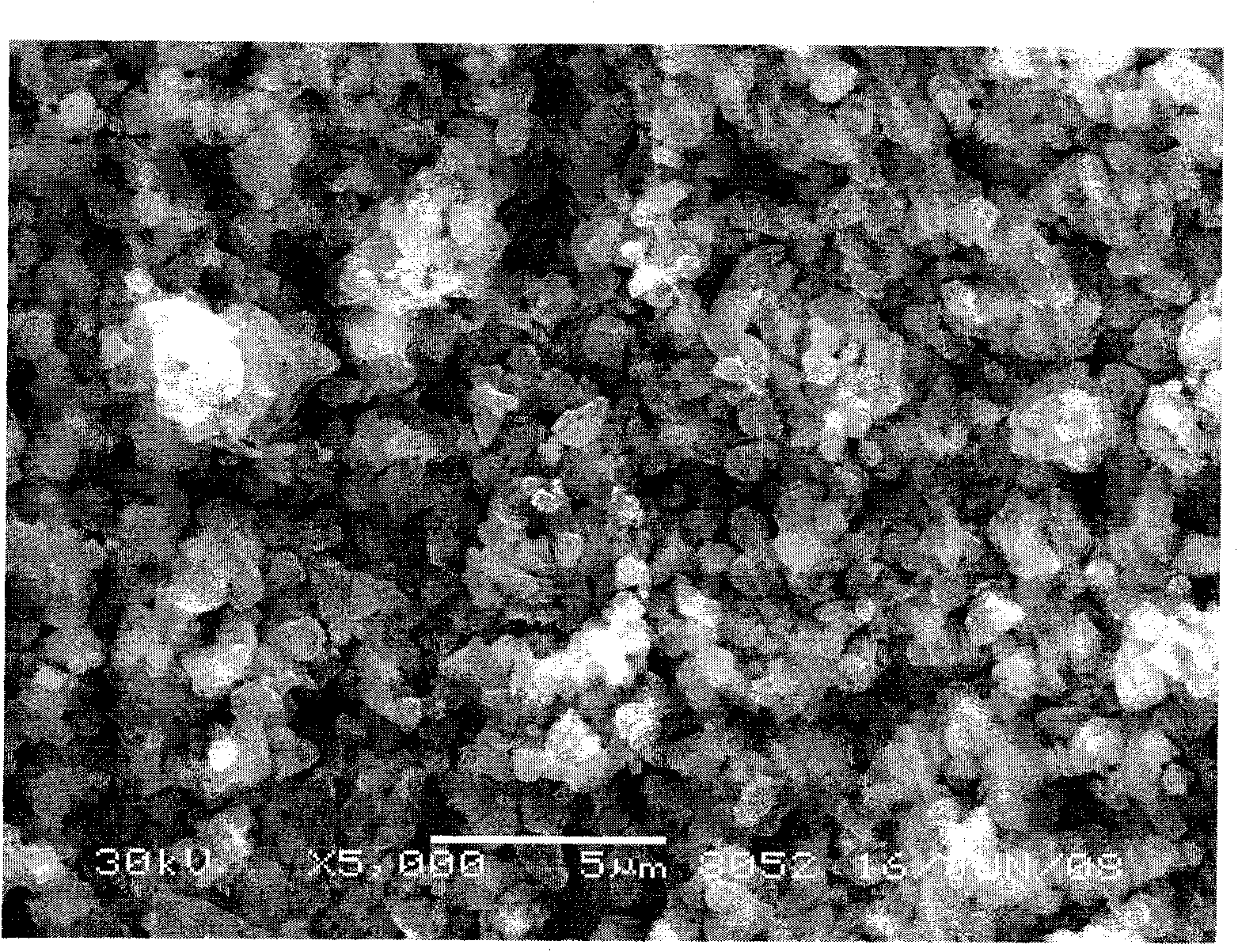

Embodiment 1

[0037] Weigh 7.62g analytical pure Li 2 CO 3 , and then weigh 20.00g of rutile TiO according to Li:Ti=4.12:5 2 , after mixing the two, put them into a PTFE ball mill tank, ball mill and mix them in an anhydrous ethanol medium for 2 hours, and then put them into a vacuum drying oven for 8 hours at 120°C.

[0038] Put it in a high-temperature resistance furnace in a crucible, carry out pre-firing reaction under air conditions, control the heating rate at 5°C / min, raise the temperature to 650°C for 6 hours, and cool to room temperature with the furnace to obtain the mesophase product.

[0039] Press Li 4 Ti 5 o 12 The target carbon content in the / C composite material is 2wt%, add 0.46g of starch respectively, ball mill and mix in anhydrous ethanol medium for 2h, and then put it into a vacuum drying oven for 8h at 120°C. After drying in an atmosphere furnace in N 2 Under a protective atmosphere, raise the temperature to 800 ° C for 6 hours, and then cool with the furnace. ...

Embodiment 2

[0048] Weigh 7.62g analytical pure Li 2 CO 3 , and then weigh 20.00g of amorphous TiO according to Li:Ti=4.12:5 2 , after mixing the two, put them into a PTFE ball mill jar, ball mill and mix them in isopropanol medium for 2 hours, and then put them into a vacuum drying oven for 8 hours at 120°C.

[0049] Put it in a high-temperature resistance furnace in a crucible, carry out pre-firing reaction under air conditions, control the heating rate at 5°C / min, raise the temperature to 650°C for 6 hours, and cool to room temperature with the furnace to obtain the mesophase product.

[0050] Press Li 4 Ti 5 o 12 The target carbon content in the / C composite material is 3wt%, adding 0.69g of glucose, ball milling and mixing in isopropanol medium for 2h, and then drying in a vacuum oven at 120°C for 8h. After drying in an atmosphere furnace in N 2 Under a protective atmosphere, raise the temperature to 800 ° C for 8 hours, and then cool with the furnace. The resulting product is ...

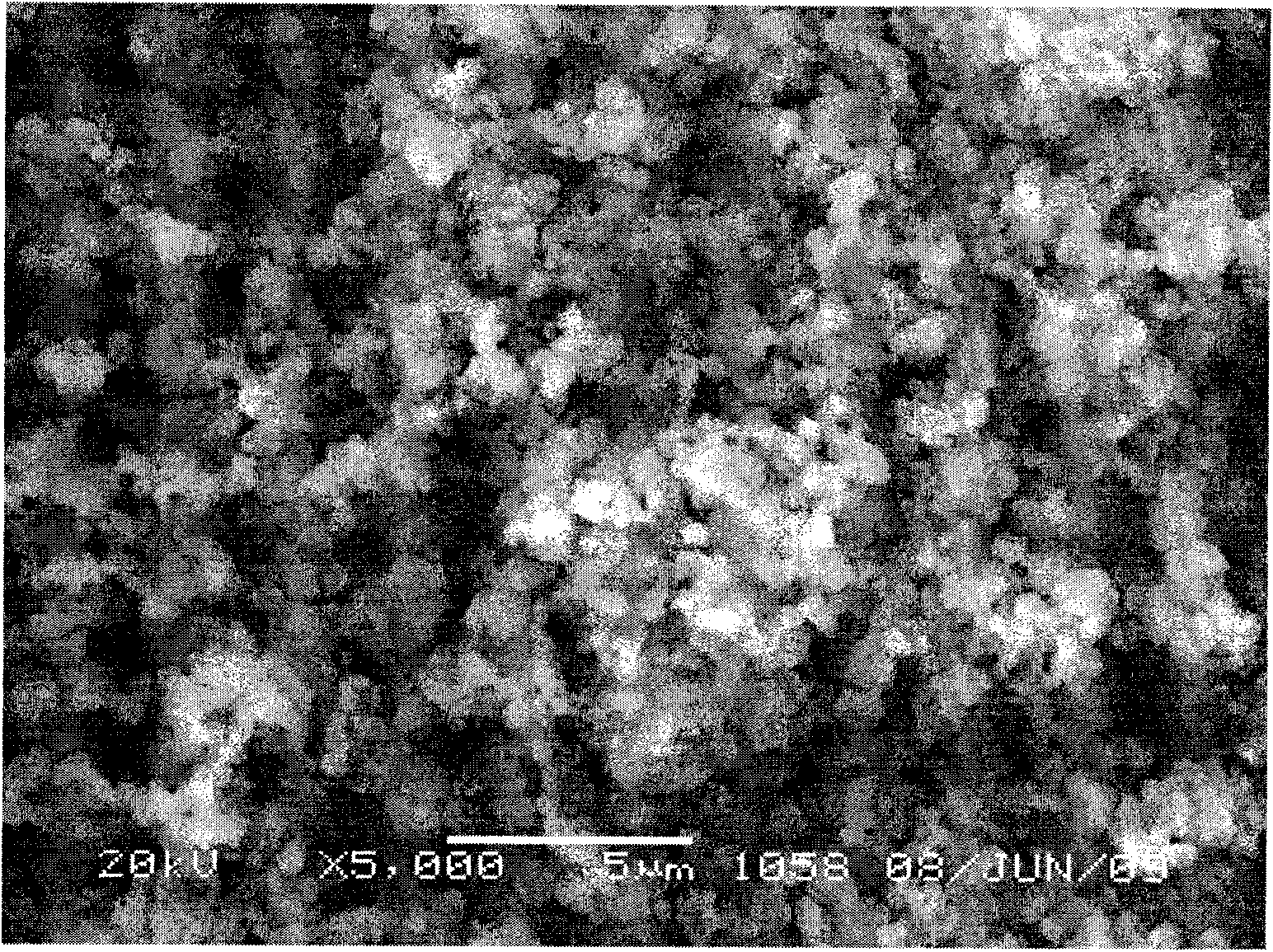

Embodiment 3

[0054] Weigh 7.62g analytical pure Li 2 CO 3 , and then weigh 20.00g anatase TiO according to Li:Ti=4.12:5 2 , after mixing the two, put them into a PTFE ball mill jar, ball mill and mix them in isopropanol medium for 2 hours, and then put them into a vacuum drying oven for 8 hours at 120°C.

[0055] Put it in a high-temperature resistance furnace in a crucible, carry out pre-firing reaction under air conditions, control the heating rate at 5°C / min, raise the temperature to 680°C for 6 hours, and cool to room temperature with the furnace to obtain the mesophase product.

[0056] Press Li 4 Ti 5 o12 The target carbon content in the / C composite material is 2wt%, adding 0.46g of glucose, ball milling and mixing in isopropanol medium for 2h, and then drying in a vacuum oven at 120°C for 8h. After drying, the temperature was raised to 900°C for 6 hours in an atmosphere furnace under an argon protective atmosphere, and then cooled with the furnace. The resulting product is Li ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com