Method for regenerating solvent for desulfurizing and dephophorizing tail gas of yellow phosphorus by sections and used device

A yellow phosphorus tail gas and solvent technology, which is applied in the field of gas purification, can solve the problems of unsatisfactory dephosphorization effect, low phosphorus capacity of the catalyst, and increased catalyst resistance, so as to eliminate secondary pollution, prolong the regeneration cycle, and reduce consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

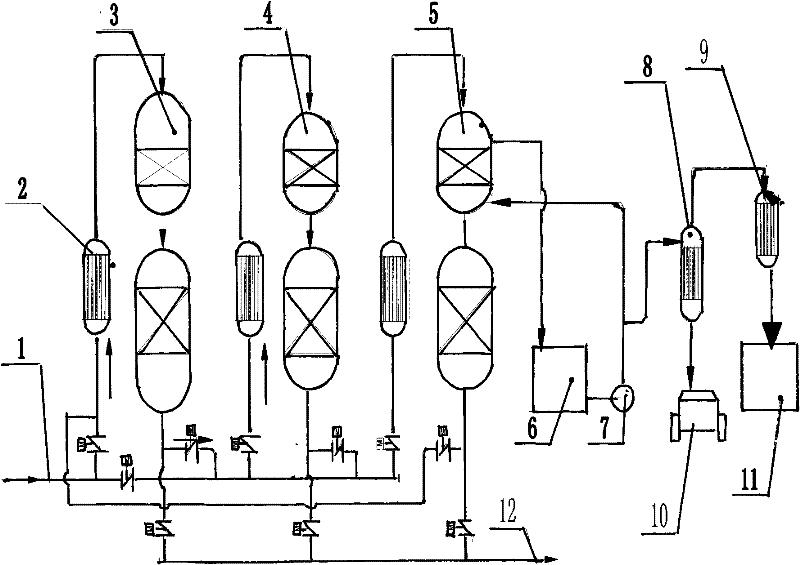

[0035] Embodiment 1: the amount of yellow phosphorus tail gas is at 3000m 3 / h or more, when there is a high requirement for impurities in the tail gas, two devices are used in series to use one device regeneration process. The yellow phosphorus tail gas enters the heater 2 from the yellow phosphorus tail gas pipe 1, is heated to 100-120°C, enters the 1# adsorber 3, enters the #2 adsorber 4 after the first adsorption, and is discharged from the yellow phosphorus after the second adsorption The tail gas outlet 12 is sent to the next process.

[0036] Adsorber 3# is regenerated, and the desulfurizer in the upper stage of the adsorber is extracted with 15% ammonium sulfide solution, and the saturated ammonium polysulfide solution is stored in the saturated ammonium polysulfide storage tank 6, and is sent to the evaporator 8 with the solution pump 7. Direct steam or indirect steam is heated and decomposed, condensed into ammonium sulfide solution in condenser 9 and returned to am...

Embodiment 2

[0037] Embodiment 2: the amount of yellow phosphorus tail gas is at 3000m 3 / h or less, where the requirements for impurities in the tail gas are not too high, use one adsorber and one regeneration process, and attach figure 1 It is enough to cancel 3# adsorber 5, the yellow phosphorus tail gas enters the heater 2 from the yellow phosphorus tail gas pipe 1, heats up to 100-120°C, enters the 1# adsorber 3, and is sent from the yellow phosphorus tail gas outlet 12 to Next process.

[0038] 2# adsorber 4 is regenerated, the desulfurizer in the upper part of the adsorber is extracted with 15% ammonium sulfide solution, and the saturated ammonium polysulfide solution is stored in the saturated ammonium polysulfide storage tank 6, and is sent to the evaporator 8 with the solution pump 7, Decompose with direct steam or indirect steam heating, condense into ammonium sulfide solution in condenser 9 and return in ammonium sulfide storage tank 11 for next use, granular sulfur is release...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com