Preparation method of calcium sulfonate salt with low alkali value

A technology of low-basic calcium sulfonate and alkylbenzenesulfonic acid, which is applied in the field of preparation of low-basic calcium sulfonate, can solve the problems of poor, incomplete, and easy layering reactions between phases and phases. Achieve fast speed, reduce product turbidity, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

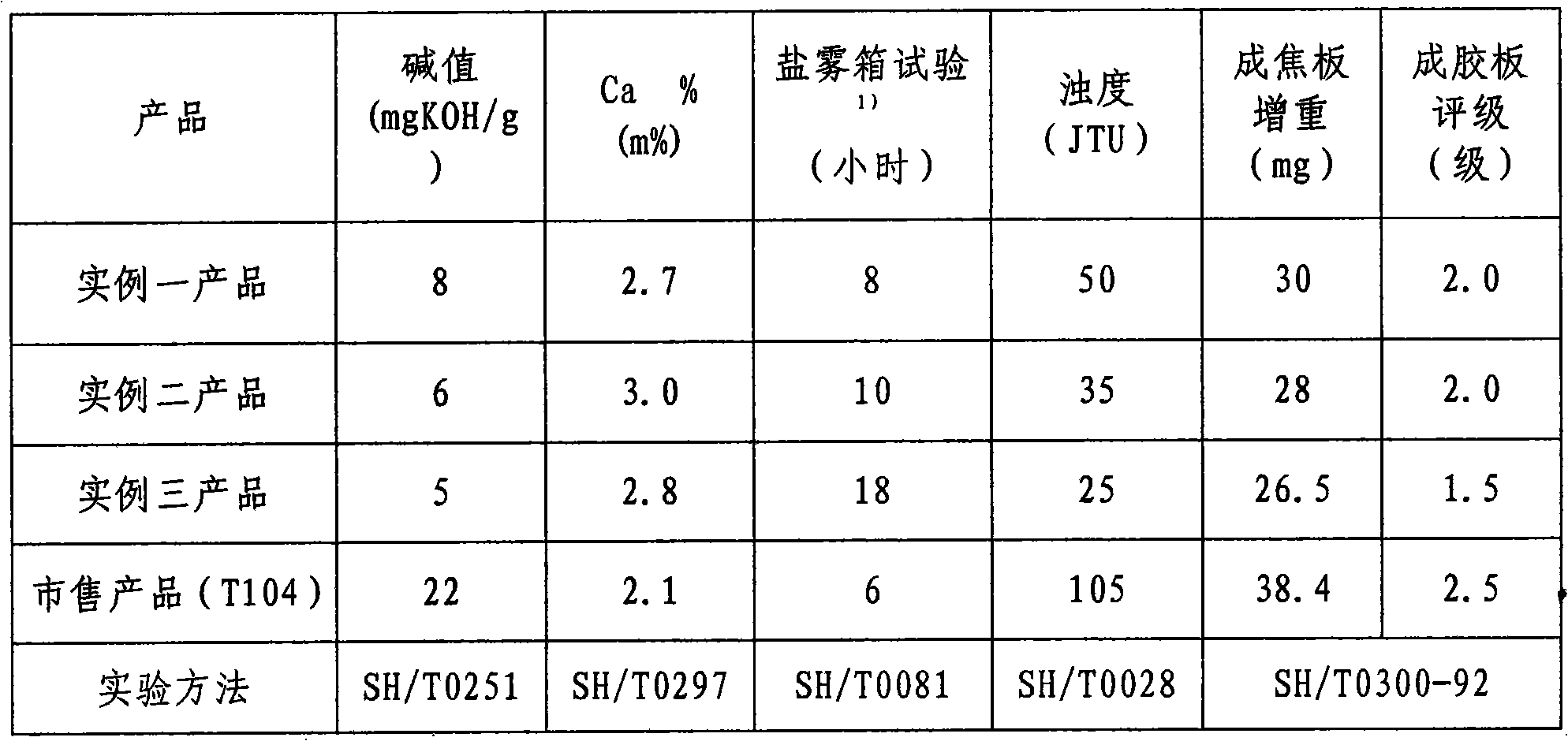

example 1

[0011] Add 200g of alkylbenzene, with an average molecular weight of 340-360, to a container equipped with a thermometer, an electric heating mantle, and a stirrer, add 150g of oleum with 20% sulfur trioxide dropwise, and control the temperature between 35-50°C, drop After adding, keep it warm for 1-4 hours, add 70g of water, and the temperature of adding water should be lower than 60°C. After adding water, purging with nitrogen, the purging temperature is 30-50°C, and absorbing tail gas with 10% sodium hydroxide aqueous solution, the pH value range of the purged gas is preferably 5.5-7.0, add 130g of 75SN, add Toluene 70g, stirred evenly, moved to a separatory funnel, static layered for 2-15 hours, separated the upper layer of crude sulfonic acid, added 20 grams of diatomite filter aid to filter, obtained refined sulfonic acid liquid, diluted sulfonic acid After testing, the acid value is 69.0mgKOH / g, and the free acid is 0.15%. Take 200g of this diluted sulfonic acid, add 1...

example 2

[0013] Add 126g of alkylbenzene to the container equipped with thermometer, electric heating mantle and stirrer, the molecular weight is about 300-320, add dropwise with 122g of oleum with 7.5% sulfur trioxide, and control the temperature between 50-80°C, After the dropwise addition, keep warm for 1-4 hours, add 40g of water, and the temperature of the water should be lower than 60°C. After adding water, purging with nitrogen, the purging temperature is 50-65°C, and absorbing tail gas with 10% sodium hydroxide aqueous solution, the pH value range of the purged gas is preferably 5.5-7.0, add 150SN 95g, add 15g of cyclohexane, stirred evenly, moved to a separatory funnel, static layered for 2-15 hours, separated the crude sulfonic acid in the upper layer, added 14g of diatomite filter aid to filter, and obtained refined alkylbenzenesulfonic acid, diluted After testing, the acid value of the final sulfonic acid is 85.0mgKOH / g, and the free acid is 0.13%. Take 265g of this diluted...

example 3

[0015] Add 100g of alkylbenzene in the container that thermometer, electric heating mantle, stirrer are housed, the carbon chain of alkylbenzene is C22-C24, molecular weight 380-400, drips with 100g of fuming sulfuric acid containing 10% sulfur trioxide, temperature Control it between 35-50°C, keep it warm for 1-4 hours after the dropwise addition, add 50g of water, and the temperature of adding water should be lower than 60°C. After adding water, purging with nitrogen, the purging temperature is 50-60°C, and absorbing tail gas with 10% sodium hydroxide aqueous solution, the pH value range of the purged gas is preferably 5.5-7.0, add 500SN50g, add solvent Oil (distillation range 90°C-120°C) 30g, stirred evenly, moved to a separatory funnel, static layered for 2-15 hours, separated the upper layer of crude sulfonic acid, added 12 grams of diatomaceous earth filter aid to filter, and obtained refined The sulfonic acid solution has an acid value of 72.2mgKOH / g and a free acid con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com