Preparation method for titanium dioxide photocatalyst doped with metal ion

A technology of metal ions and photocatalysts, applied in the field of environmental technology and nanomaterials, can solve problems such as limited application range, complicated preparation equipment, and complicated operation, and achieve the effects of improving photocatalytic activity, expanding absorption range, and enhancing antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

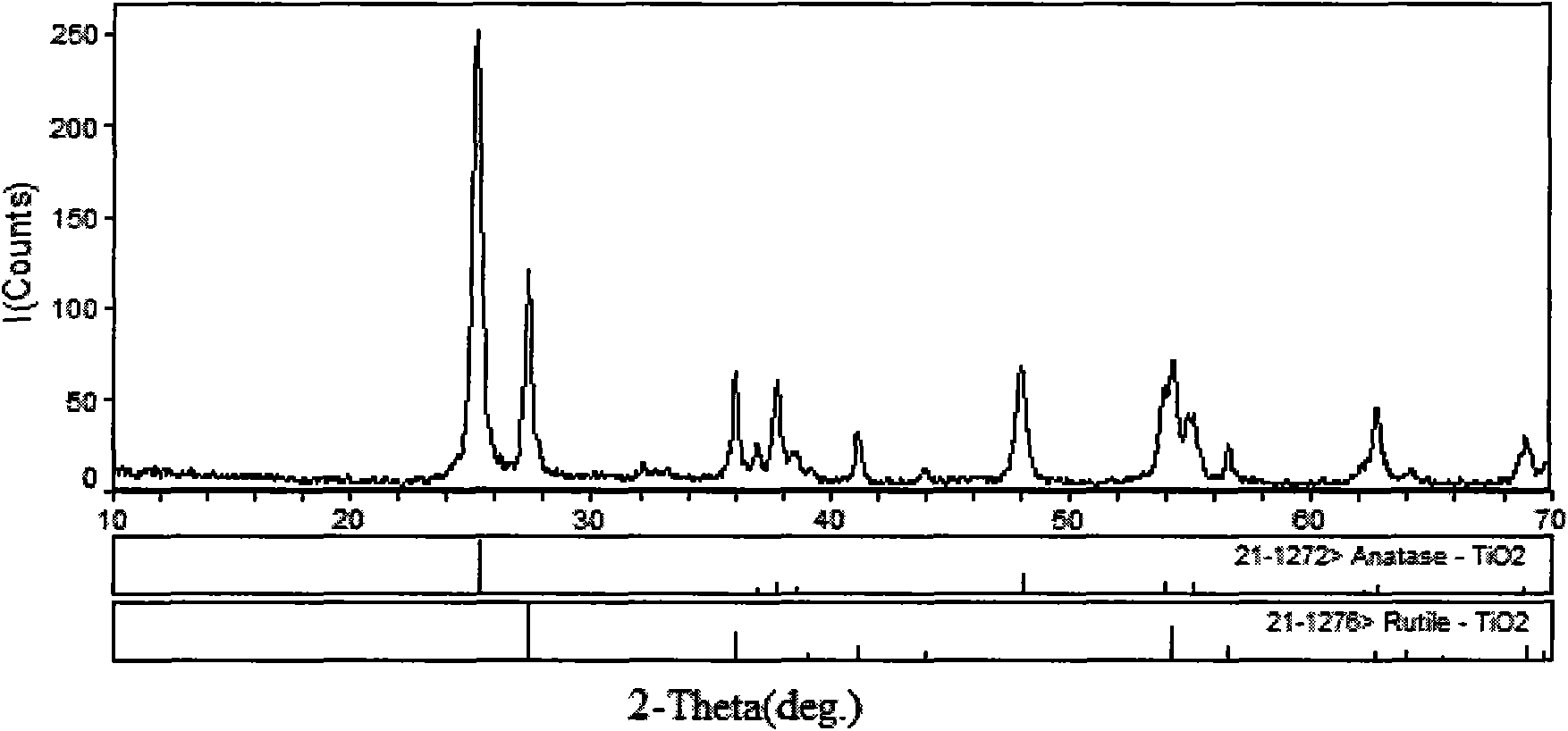

[0014] Embodiment 1: At first, preparation concentration is the HNO of 1mol / L 3 solution, take 20ml of HNO 3 solution and add 0.0025g of AgNO to it 3 Obtain solution A; Next, place solution A on a magnetic stirrer and heat and stir, and when the solution is volatilized to 15ml, add 0.7ml of chemically pure tetra-n-butyl titanate (C 16 h 36 o 4 Ti) was dissolved in solution A, continued heating and stirring until Ag ion-doped TiO 2 crystal; finally, TiO was doped with Ag ions 2 The crystal is ground in a mortar, then sintered in a muffle furnace at 200°C for 2 hours, cooled naturally in the furnace, ground again in a mortar, and the obtained powder is placed in a muffle furnace and sintered at 550°C After 3 hours, the furnace was naturally cooled to room temperature to obtain an Ag ion-doped titania photocatalyst with an Ag doping mass of 1%. see figure 1 , the results show that the obtained sample is a mixed crystal of anatase and rutile crystals mainly composed of anat...

Embodiment 2

[0015] Embodiment 2: At first, preparation concentration is the HNO of 1.2mol / L 3 solution, take 20ml of HNO 3 solution and added 0.0072g of Fe(NO 3 ) 3 Obtain solution A; Next, place solution A on a magnetic stirrer and heat and stir, and when the solution is volatilized to 15ml, add 0.7ml of chemically pure tetra-n-butyl titanate (C 16 h 36 o 4 Ti) was dissolved in solution A, continued heating and stirring until Fe ion-doped TiO 2 crystal; finally, Fe ions doped TiO 2 The crystal is ground in a mortar, then sintered in a muffle furnace at 200°C for 2 hours, cooled naturally in the furnace, ground again in a mortar, and the obtained powder is placed in a muffle furnace and sintered at 550°C After 3 hours, the furnace was naturally cooled to room temperature to obtain a Fe ion-doped titania photocatalyst with a Fe doping mass of 1%-.

Embodiment 3

[0016] Embodiment 3: at first, preparation concentration is the HNO of 1.4mol / L 3 solution, take 20ml of HNO 3 solution and added 0.0049g of Cu(NO 3 ) 2 Obtain solution A; Next, place solution A on a magnetic stirrer and heat and stir, and when the solution is volatilized to 15ml, add 0.7ml of chemically pure tetra-n-butyl titanate (C 16 h 36 o 4 Ti) was dissolved in solution A, continued heating and stirring until Cu ion-doped TiO 2 crystal; finally, Cu ions doped TiO 2 The crystal is ground in a mortar, then sintered in a muffle furnace at 200°C for 2 hours, cooled naturally in the furnace, ground again in a mortar, and the obtained powder is placed in a muffle furnace and sintered at 550°C After 3 hours, the furnace was naturally cooled to room temperature to obtain a Cu ion-doped titania photocatalyst with a Cu doping mass of 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com