Reverse osmosis water treatment method and equipment with high desalination and high water productivity

A technology of reverse osmosis water and treatment method, which is applied in osmosis/dialysis water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Low problems, to achieve the effect of reduced operating costs, stable system operation, and reduced investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

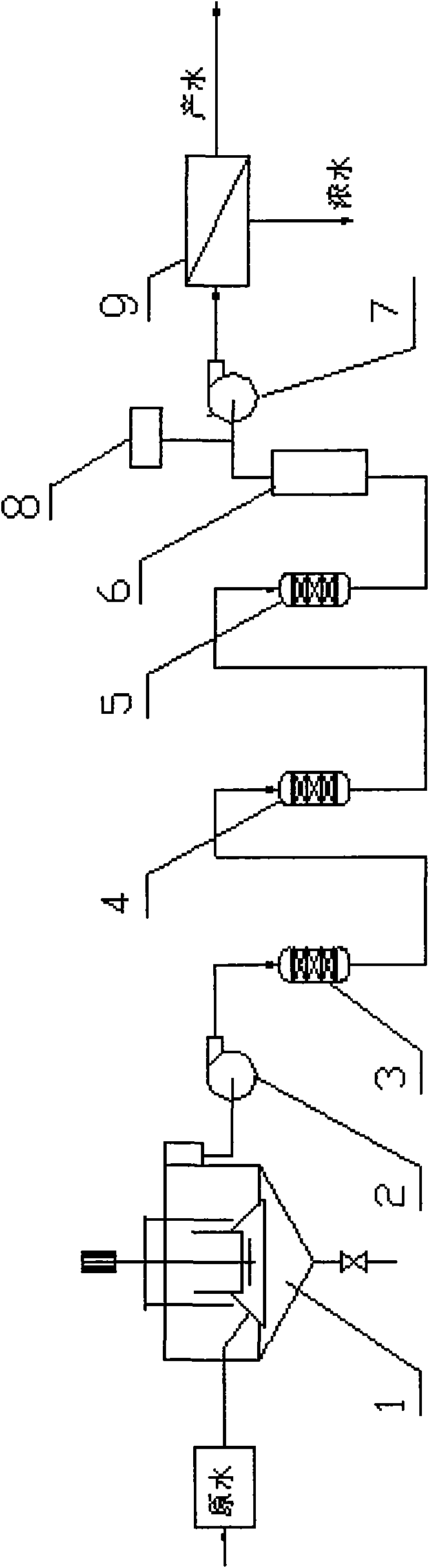

[0045] The high desalination and high water production rate reverse osmosis water treatment equipment of the present invention includes a coagulation clarification and filtration system 1, a raw water pump 2, and a depth filtration system 3. The system uses a multi-media filter, and an ion exchange softening system 4. The system uses two stages Single-layer fixed ion exchange softening bed, degassing system 5, degassing tower selected for degassing system, decarburization water tank 6, reverse osmosis high pressure pump 7, dosing system 8, high desalination and high water production rate reverse osmosis system 9. The method of the present invention comprises that the raw water is industrial sewage with high turbidity, high silicon content and high COD, and the raw water is filtered in the coagulation clarification filtration system 1 to remove suspended particles, colloids and some organic matter in the water; and then pass the raw water pump 2 Send to the deep filtration syste...

Embodiment 2

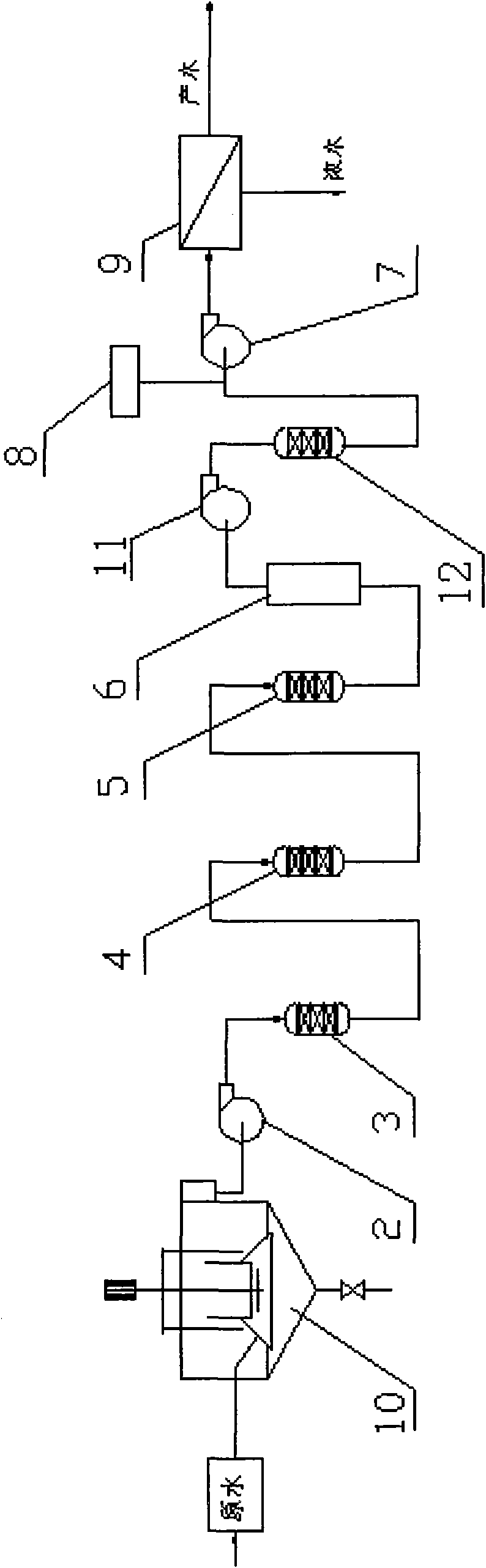

[0047] The reverse osmosis water treatment equipment with high desalination and high water production rate of the present invention includes a lime softening system 10, a raw water pump 2, and a deep filter system 3. The system uses a high-efficiency fiber filter, and an ion exchange softening system 4. The system uses a single-layer Floating ion exchange softening bed, degassing system 5, the system uses degassing membrane device, decarbonization water tank 6, reverse osmosis water inlet pump 11, 5 micron precision filter 12, reverse osmosis high pressure pump 7, dosing system 8, high desalination High water production rate reverse osmosis system9. The method of the present invention comprises that the raw water is the mixed water of industrial sewage after biochemical treatment and polluted surface water, the raw water first enters the lime softening system 10, adopts the lime softening process to remove part of the hardness, and reduces the load of the ion exchange softening...

Embodiment 3

[0049] Same as Example 2, wherein the ion exchange softening system 4 selects a two-stage single-layer fixed ion exchange softening bed, adopts soda lime softening process to remove hardness in the lime softening system, adds scale inhibitor at 0.5ppm, and produces water recovery rate of 85%. %about.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com