Thermal-decomposing pore-forming self-heat-insulating bearing sintered product and preparation method thereof

A technology of sintered products and thermal decomposition, which is applied in the direction of ceramic products, clay preparation devices, chemical instruments and methods, etc., can solve the problems of high heat transfer, difficult construction, small cavities, etc., so as to save land resources and achieve good thermal insulation effect , the effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

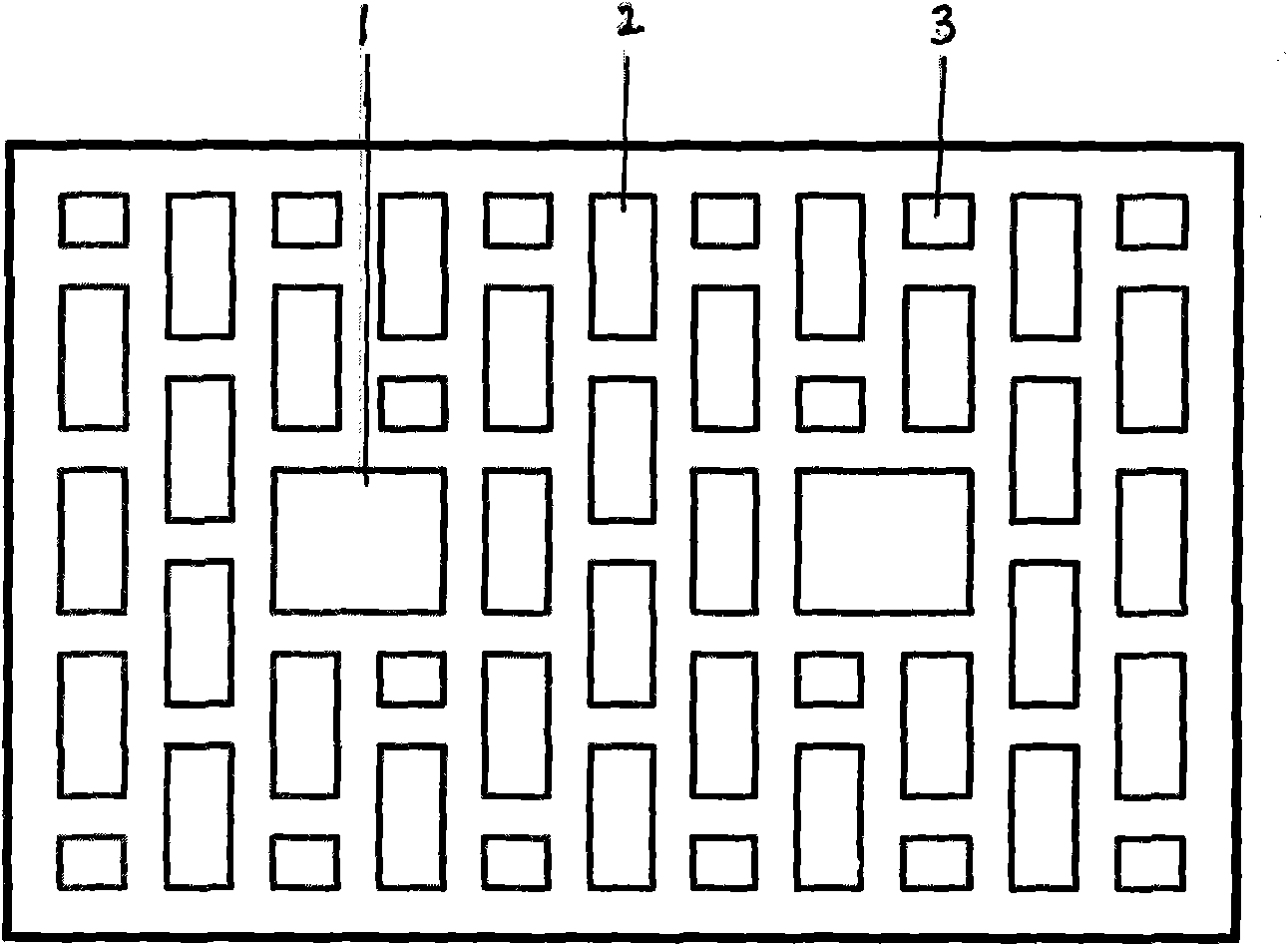

[0023] Embodiment 1: three kinds of raw materials that tailings, sodium soil, calcium oxalate mass ratio are 50: 45: 5 are stirred evenly (the particle diameter of tailings, sodium soil is less than 0.15mm, and the particle diameter of calcium oxalate is less than 0.075mm), Add a small amount of water to granulate, age for 1 to 3 days, and after obtaining suitable plasticity, make the mud material be molded into attached bricks in a vacuum extruder through a porous brick mold. figure 1 The green body of mesopore type and size is then dried at a temperature of 50±5°C for 2 to 4 days, and fired at 1070±20°C for 5 hours to obtain a heat transfer coefficient of 0.441W / m2·°C. The compressive strength is 24.3MPa, the apparent density is 1.56g / cm3, and other indicators also meet the requirements of GB13544-2000 and GB6566-2001. It is a self-insulating load-bearing sintered product.

Embodiment 2

[0024] Embodiment 2: three kinds of raw materials that coal gangue, sodium soil, basic magnesium carbonate mass ratio are 60: 30: 10 are stirred evenly (the particle diameter of coal gangue, sodium soil is less than 0.15mm, and the particle diameter of basic magnesium carbonate is less than 0.075mm), adding a small amount of water to granulate, aging for 1 to 3 days, and after obtaining suitable plasticity, the mud is formed into attached bricks in a vacuum extruder through a porous brick mold. figure 1 The green body with mesopore type and size is then dried at a temperature of 50±5°C for 2 to 4 days, and fired at 1070±20°C for 6 hours to obtain a heat transfer coefficient of 0.425W / m2·°C. The compressive strength is 23.1MPa, the apparent density is 1.47g / cm3, and other indicators also meet the requirements of GB13544-2000 and GB6566-2001. It is a self-insulating load-bearing sintered product.

Embodiment 3

[0025] Embodiment 3: the four kinds of raw materials that coal gangue, shale, double fly powder, dolomite mass ratio are 36:54:5:5 are stirred evenly (the particle diameter of coal gangue, shale is less than 0.15mm, double fly powder, dolomite The particle size is less than 0.075mm), add a small amount of water to granulate, and age for 1 to 3 days. After obtaining suitable plasticity, the mud is formed into an attached brick through a porous brick mold in a vacuum extruder. figure 1 The green body with mesopore type and size is then dried at a temperature of 50±5°C for 2 to 4 days, and fired at 1050±20°C for 6 hours to obtain a heat transfer coefficient of 0.402W / m2·°C. The compressive strength is 21.2MPa, the apparent density is 1.43g / cm3, and the other indicators also meet the requirements of GB13544-2000 and GB6566-2001. It is a self-insulating load-bearing sintered product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com