Method for starting air-liquid two-phase bacterium culture and reaction device for biologic treatment of waste gas

A bioreactor and biological treatment technology, applied in the direction of microorganism-based methods, specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, etc., can solve the danger of long start-up time and difficult operation of bioreactors , Single domestication method and other problems, to achieve the effect of rich microbial species, good adaptability, efficient and stable removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

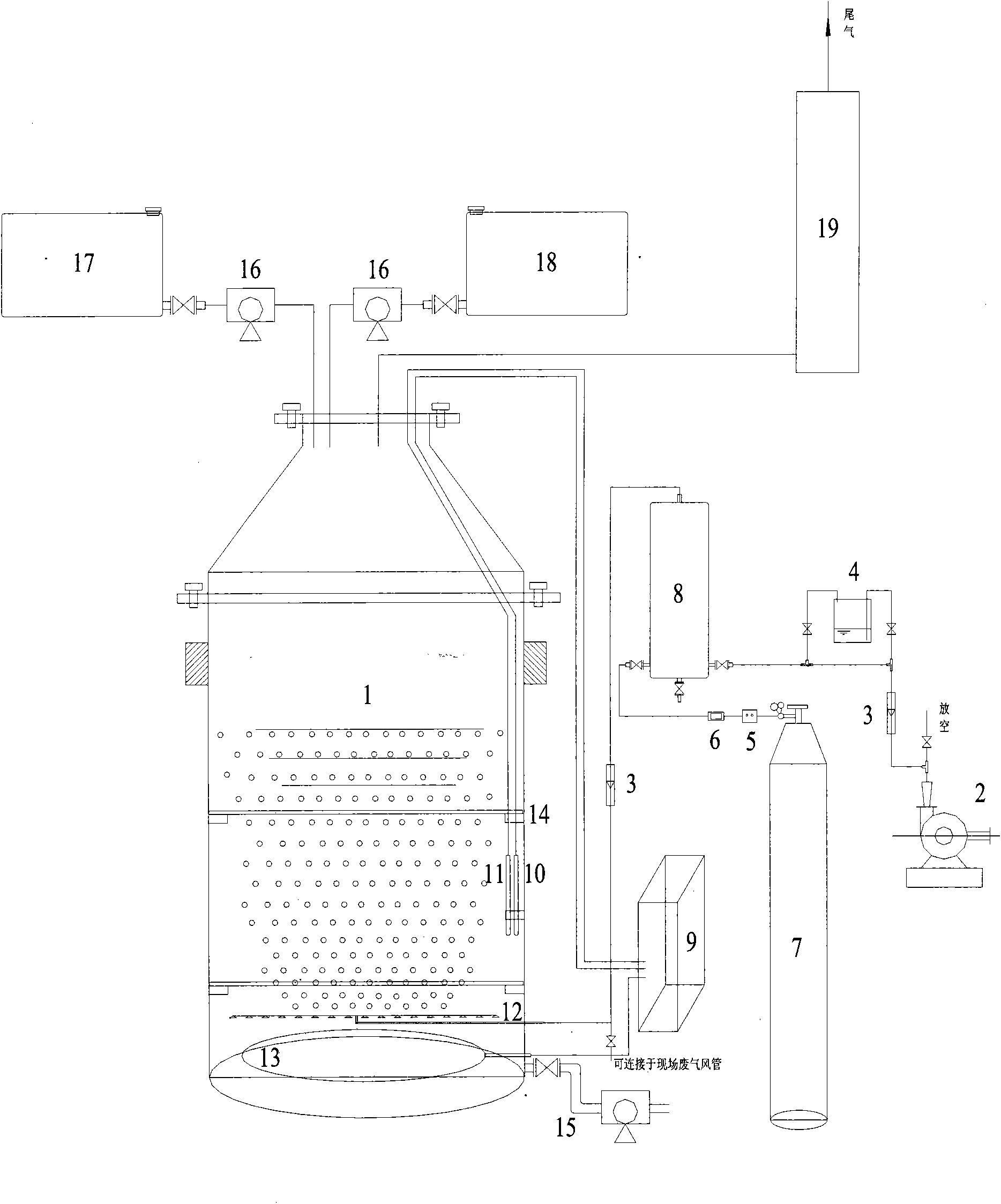

[0025] Use biological trickling filter bed and biological filter bed series process to treat mixed waste gas from sewage treatment of a pharmaceutical factory. The waste gas contains H 2 S concentration is 300~500mg / m 3 , Containing VOCs (mainly toluene and dichloromethane, etc.) concentration is 250~2000mg / m 3 , Adopting this gas-liquid two-phase culture method and its special device has unique advantages. First, use the high-efficiency microbial preparations screened, cultivated and prepared and the activated sludge mixture of the sewage treatment aerobic biochemical tank of the pharmaceutical factory as bacterial strains, put the toluene and dichloromethane solution in the volatile liquid pollutant storage tank, and turn on The fan uses air to blow toluene and dichloromethane into the mixing tank, and at the same time the simulated H 2 S waste gas is passed into the mixing tank together, and after being mixed in the mixing tank, it is passed into the culture tank (1). The air...

Embodiment 2

[0029] The biological trickling filter bed process is used to treat the mixed waste gas of a chemical plant, which mainly contains benzene, toluene and xylene and other benzene compounds. 2 S and organic sulfur compounds such as methyl mercaptan, ethyl mercaptan, dimethyl disulfide, etc. The concentration of benzene compounds in the exhaust gas is 60~800mg / m 3 , H 2 S concentration is 5~40mg / m 3 , The concentration of organic sulfide is 11~53mg / m 3 , Adopt this gas-liquid two-phase bacteria culture device, use the activated sludge of the on-site sewage treatment aerobic biochemical tank as the bacteria, and after 8 days of culture method in the field as in Example 2, the pH of the mixed solution drops from 7.4 to 2.9 Then the pH of the culture tank was controlled between 3.8 and 4.2. After another 8 days of cultivation, the concentration of suspended solids in the culture tank increased significantly. Based on experience, it can be considered that the mixed bacterial solution has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com