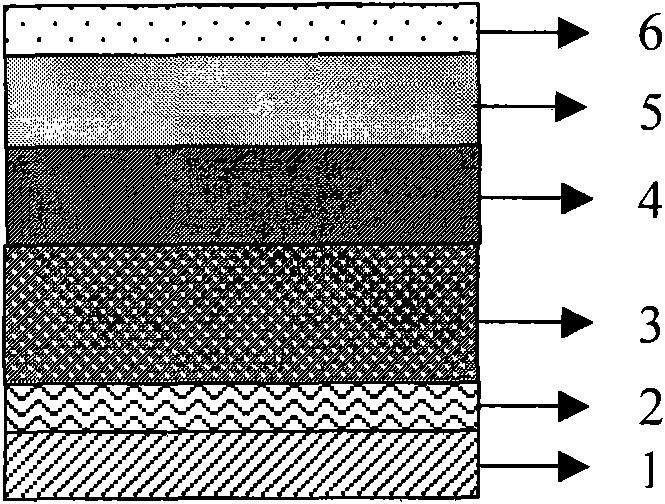

Non-vacuum solar spectrum selective absorption film and preparation method thereof

A technology of absorbing film and solar spectrum, which is applied in the field of solar thermal utilization materials, can solve the problems of low radiation performance and low resistivity, and achieve good spectral selective absorption, low cost and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

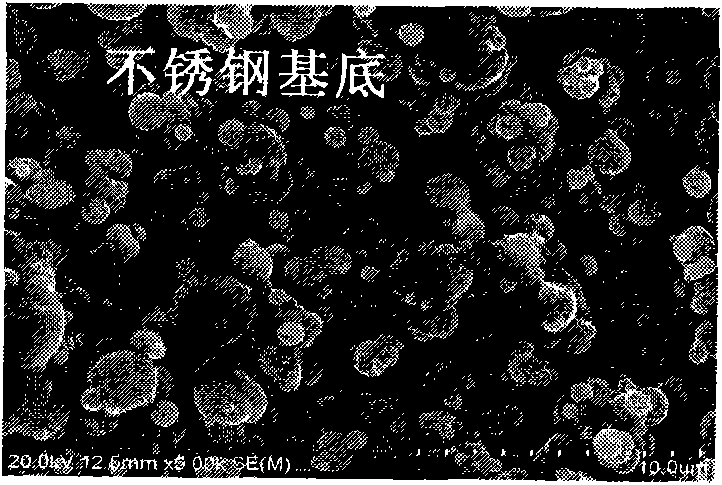

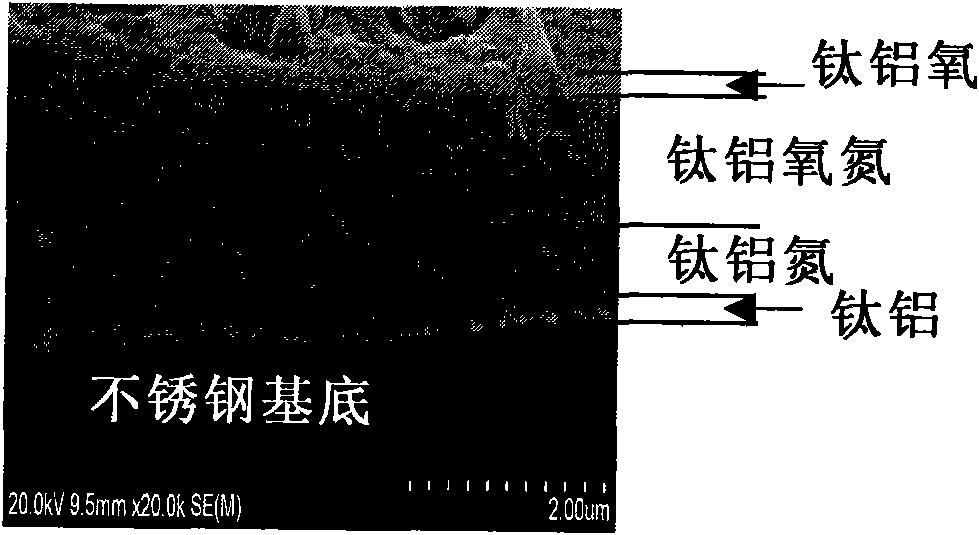

Embodiment 1

[0042] (1) The TX-1000 multi-target composite coating machine produced by Beijing Tianruixing Co., Ltd. was used for coating; in order to improve the bonding force between the titanium nitrogen oxide film and the substrate, the substrate material was respectively soaked in sulfuric acid, detergent, and detoxification before being placed in the vacuum chamber. Sonicate in ionized water, gasoline, and ethanol for 5 to 20 minutes, then dry; place in a vacuum chamber, bake at 100 degrees Celsius for 10 minutes, and the experimental background vacuum is 3×10 -3 Pa, before the sample is deposited, argon is introduced to a pressure of 8×10 -2 Pa, the cathode current is 75 amps, and the negative bias voltage of 800 volts bombards the surface of the sample with argon ions to remove the gas and impurities adsorbed on the surface and expose a clean surface. When the background vacuum in the vacuum sputtering chamber is better than 3×10 -3 Introduce appropriate amount of reaction gases n...

Embodiment 2

[0049] (1) The TX-1000 multi-target composite coating machine produced by Beijing Tianruixing Co., Ltd. was used for coating; in order to improve the bonding force between the titanium nitrogen oxide film and the substrate, the substrate material was respectively soaked in sulfuric acid, detergent, and detoxification before being placed in the vacuum chamber. Sonicate in ionized water, gasoline, and ethanol for 5 to 20 minutes, then dry; place in a vacuum chamber, bake at 100 degrees Celsius for 10 minutes, and the experimental background vacuum is 3×10 -3 Pa, before the sample is deposited, argon is introduced to a pressure of 8×10 -2 Pa, the cathode current is 75 amps, and the negative bias voltage of 800 volts bombards the surface of the sample with argon ions to remove the gas and impurities adsorbed on the surface and expose a clean surface. When the background vacuum in the vacuum sputtering chamber is better than 3×10 -3 Introduce an appropriate amount of reaction gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com