Preparation method of mangiferin

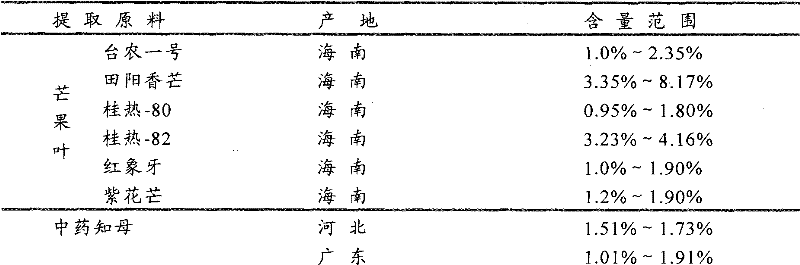

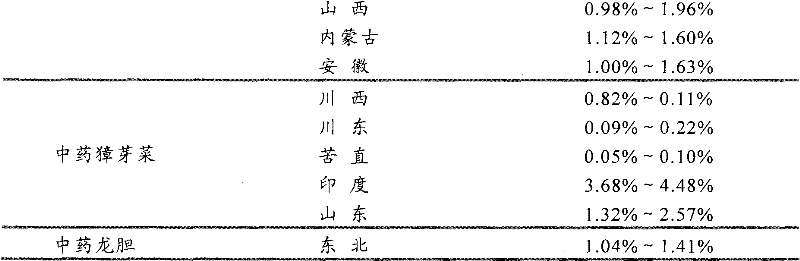

A technology for mangiferin and raw materials, applied in the field of compound extraction technology, can solve the problems of high cost, cumbersome preparation process, insufficient deep processing of products, etc., and achieve the effects of mild production process conditions, reduced production cost, and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

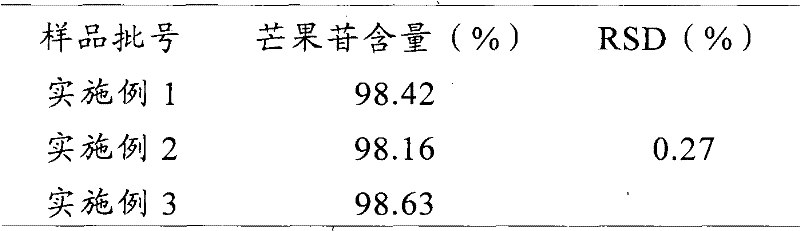

Examples

Embodiment 1

[0027] Take 100g of dry leaves of Mangiferaindica L., a plant of Anacardiaceae, crush them, soak them in 800ml of cellulase aqueous solution with pH=4.5 (140μg of cellulase per g of crude drug) for 0.5hr, then enzymatically hydrolyze in a water bath at 50°C for 2hr, and stir thoroughly , filter, get the dregs of the medicine and degrease twice with 600ml of petroleum ether, filter, reclaim the petroleum ether, extract the dregs of medicine twice with 75% ethanol equivalent to 6 times the amount of the original medicinal material, combine the extracts, and reclaim the ethanol , spray-dried to obtain a dry powder, then dissolve the powder with 20% ethanol, centrifuge for 15 minutes at a speed of 6000 rpm, take the filtrate, concentrate until dry to obtain the crude mangiferin, and recrystallize twice with 40% ethanol. Finally, the fine mangiferin was obtained.

Embodiment 2

[0029] Take 100 g of dry leaves of Mangiferaindica L. of Anacardiaceae, crush them, and use 1000 ml of cellulase (140 μg of cellulase per g of crude drug) and pectinase (80 μg of pectinase per g of crude drug) at a ratio of 1:1 Soak in the aqueous solution for 0.5hr, then enzymatically hydrolyze in a water bath at 50°C for 4hr, stir well, and centrifuge for 30min at a speed of 10,000rpm, take the dregs and use 1000ml of petroleum ether to degrease twice, filter, and recover petroleum ether , the dregs are extracted three times with 75% ethanol equivalent to 10 times the amount of the original medicinal material, the extracts are combined, the ethanol is recovered, and spray-dried to obtain a dry powder, then the powder is dissolved with 20% ethanol, centrifugally filtered, and the filtrate is concentrated to The crude mangiferin was obtained by drying, and recrystallized three times with 40% ethanol to finally obtain the refined mangiferin.

Embodiment 3

[0031] Take 100 g of mango leaves, soak them in 800 ml of cellulase aqueous solution with pH=4.5 (add 140 μg of cellulase per g of crude drug) for 0.5 hr, then enzymatically hydrolyze in a water bath at 50 °C for 2 hr, stir well, filter, and take the dregs for each The sherwood oil of 600ml carries out degreasing treatment twice, filters, reclaims sherwood oil, and dregs is extracted twice with the 75% ethanol that is equivalent to 6 times of former medicinal material, merges extract, reclaims ethanol, sprays and dries to obtain dry powder, and then The powder is dissolved with 20% ethanol, filtered, the filtrate is taken, concentrated to dryness to obtain crude mangiferin, and then recrystallized twice with 40% ethanol to finally obtain fine mangiferin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com