Lachnum and method for preparing melanin by liquid fermentation thereof

A technology of Trichodia granulosa and liquid fermentation, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., and can solve the problem of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

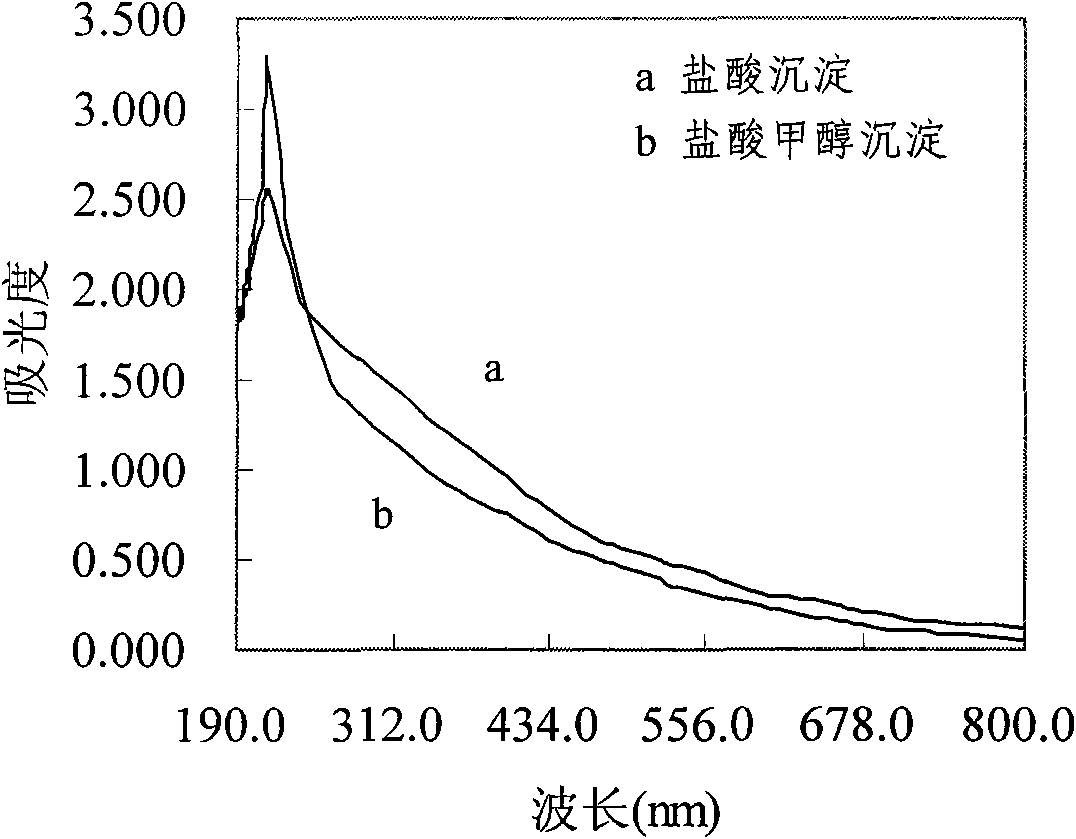

Image

Examples

Embodiment 1

[0019] The sporocarp of Lachnum CCTCC M 209193 of the present invention is collected from Huangshan Mountain, Anhui Province, and is separated and purified by a tissue separation method: take fresh Lachnum sporocarp, soak it with 75% alcohol for 10-30s Then soak in 0.1% mercuric chloride solution for 5-8 minutes, and then wash 2-3 times with sterile water, cut the fruiting bodies into 2-4 pieces, inoculate them in PDA medium, and cultivate them at a constant temperature of 23-25°C. After the silk grows, take the bacterial blocks with the same age and shape along the edge of the colony for purification and culture, repeat 4 to 5 times, and obtain the pure culture of Lachnum CCTCC M 209193;

[0020] (1) Liquid Fermentation of Lachnum CCTCC M 209193

[0021] Inoculate the above-mentioned pure culture of Lachnum CCTCC M 209193 on a potato glucose medium (PDA medium) plate for activation. After 7 days of constant temperature cultivation at 25°C, take a piece of bacteria along the e...

Embodiment 2

[0029] The method for obtaining the pure culture of Lachnum (Lachnum) CCTCC M 209193 is the same as in Example 1;

[0030] (1) Liquid Fermentation of Lachnum CCTCC M 209193

[0031] Inoculate the above-mentioned pure culture of Lachnum CCTCC M 209193 on a potato glucose medium plate for activation, and after cultivating at a constant temperature at 23°C for 5 days, use a hole puncher with a diameter of 6 mm to take a piece of bacteria with the same age along the edge of the colony Inoculate in a 250ml Erlenmeyer flask with 50ml potato dextrose liquid fermentation medium, and after cultivating on a shaker at 160r / min for 5 days at 25°C, the seed liquid of Lachnum CCTCC M 209193 was obtained. This Lachnum (Lachnum) CCTCC M 209193 seed solution was inoculated in a 5L automatic control fermenter by 4% of the fermentation medium volume, the fermentation medium filling volume was 3L, and the ventilation rate was 2L / min. After culturing at a rotational speed of 180r / min for 10 days,...

Embodiment 3

[0038] The method for obtaining the pure culture of Lachnum (Lachnum) CCTCC M 209193 is the same as in Example 1;

[0039] (1) Liquid Fermentation of Lachnum CCTCC M 209193

[0040]Inoculate the above-mentioned pure culture of Lachnum CCTCC M 209193 on a potato glucose medium plate for activation, culture at a constant temperature of 25°C for 6 days, and use a hole puncher with a diameter of 6mm to take a piece of bacteria with the same age along the edge of the colony Inoculate in the 250ml Erlenmeyer flask that 60ml potato dextrose liquid fermentation medium is housed, at 23 ℃, with the rotating speed of 200r / min, shaker culture after 3 days, obtain Lachnum (Lachnum) CCTCC M 209193 seed liquid. This Lachnum (Lachnum) CCTCC M 209193 seed solution was inoculated in a 5L automatic control fermenter by 8% of the fermentation medium volume. Rotating speed of 200r / min, after cultivating for 12 days, suction filtration twice, the filtrate is the required fermentation broth. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com