Chemical copper plating solution for polyimide film and surface chemical copper plating method thereof

A technology of polyimide film and electroless copper plating, which is applied in the field of electroless plating, can solve the problems of no more than 50 mg/L, large environmental pollution, etc., and achieve good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

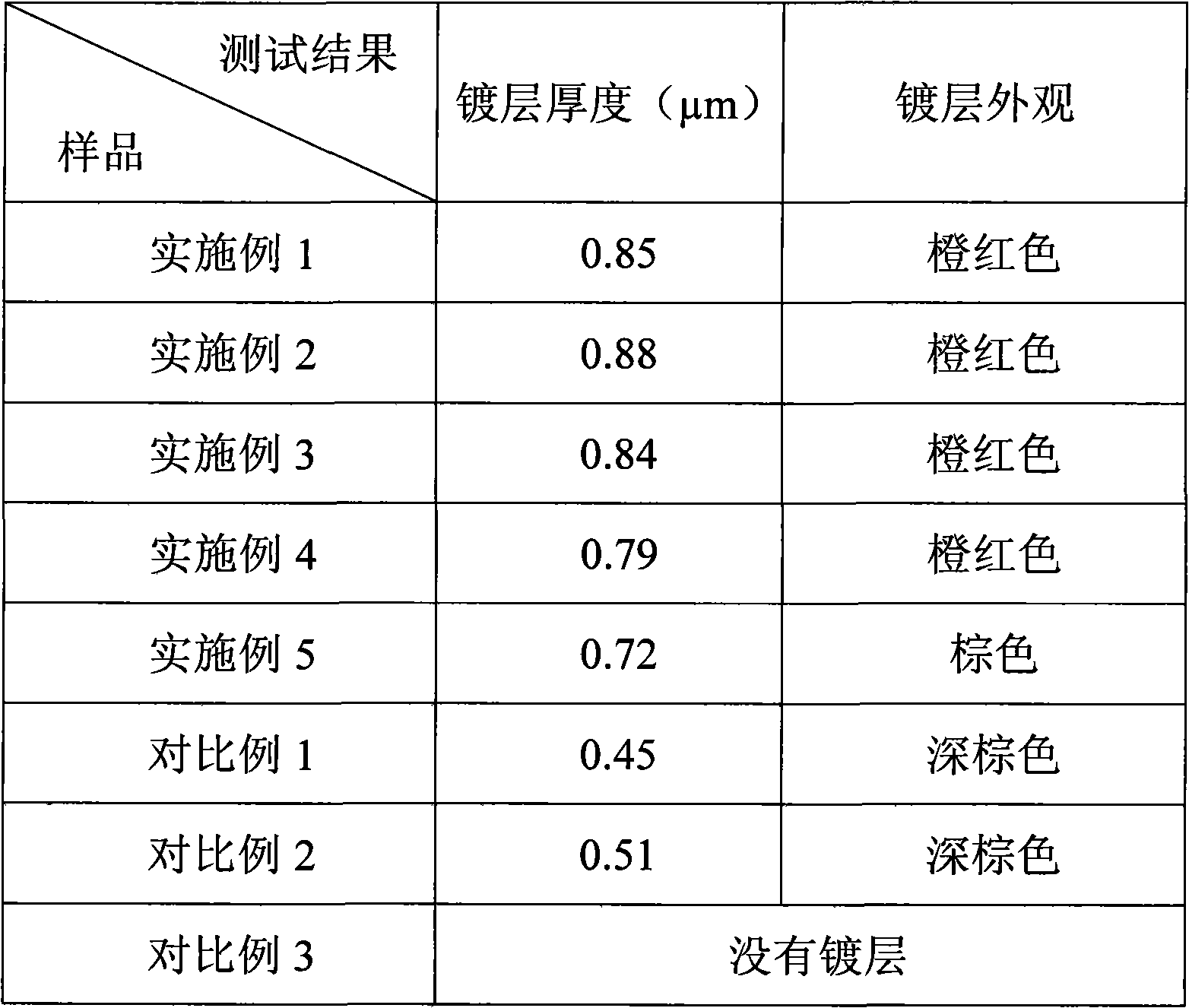

Examples

Embodiment 1

[0031] This embodiment is used to illustrate the electroless copper plating solution and surface electroless copper plating method for the polyimide film provided by the present invention.

[0032] Preparation of electroless copper plating solution: 8 grams of anhydrous copper sulfate, 3.2 grams of ascorbic acid, 25 grams of ethylenediamine tetraacetic acid, 7 mg of potassium ferrocyanide, 0.5 grams of sodium dodecylbenzenesulfonate , 0.8 grams of nickel sulfate hexahydrate, 0.5 milligrams of thiourea and 15 grams of boric acid were dissolved in deionized water to prepare 1 liter of electroless copper plating solution.

[0033] Adjust the pH value of the above electroless copper plating solution to 6.8 with sulfuric acid or ammonia water, and raise the temperature to 45°C, use nitrogen gas to bubble into the electroless copper plating solution, and introduce the polyimide film with active copper on the above electroless copper plating solution. Soak in liquid for 40 minutes. Th...

Embodiment 2

[0035] This embodiment is used to illustrate the electroless copper plating solution and surface electroless copper plating method for the polyimide film provided by the present invention.

[0036] Adopt the method identical with embodiment 1 to process above-mentioned polyimide film introducing active species copper, difference is:

[0037] Preparation of electroless copper plating solution: 20 grams of anhydrous copper sulfate, 8 grams of ascorbic acid, 60 grams of ethylenediaminetetraacetic acid, 7 mg of potassium ferrocyanide, 0.5 grams of sodium dodecylbenzenesulfonate , 3.6 grams of nickel sulfate hexahydrate, 8 milligrams of thiourea and 30 grams of boric acid were dissolved in deionized water to prepare 1 liter of electroless copper plating solution.

[0038] The polyimide plated piece obtained by the above method is denoted as A2.

Embodiment 3

[0040] This embodiment is used to illustrate the electroless copper plating solution and surface electroless copper plating method for the polyimide film provided by the present invention.

[0041] Adopt the method identical with embodiment 1 to process above-mentioned polyimide film introducing active species copper, difference is:

[0042] Preparation of electroless copper plating solution: 8 grams of anhydrous copper sulfate, 3.2 grams of ascorbic acid, 20 grams of potassium sodium tartrate tetrahydrate, 0.5 grams of n-octyl sodium sulfate, 0.9 grams of nickel chloride hexahydrate, 0.5 mg Thiourea and 15 grams of boric acid were dissolved in deionized water to prepare 1 liter of electroless copper plating solution.

[0043] The polyimide plated piece obtained by the above method is denoted as A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com