Edible powder tea oil and preparation method thereof

A technology of camellia oil and powder, which is applied in the field of edible powdered camellia oil and its preparation, can solve the problems of large loss of active ingredients of camellia oil, difficulty in adding and mixing, complicated operation, etc., achieves easy control of preparation conditions, less loss of active ingredients, good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

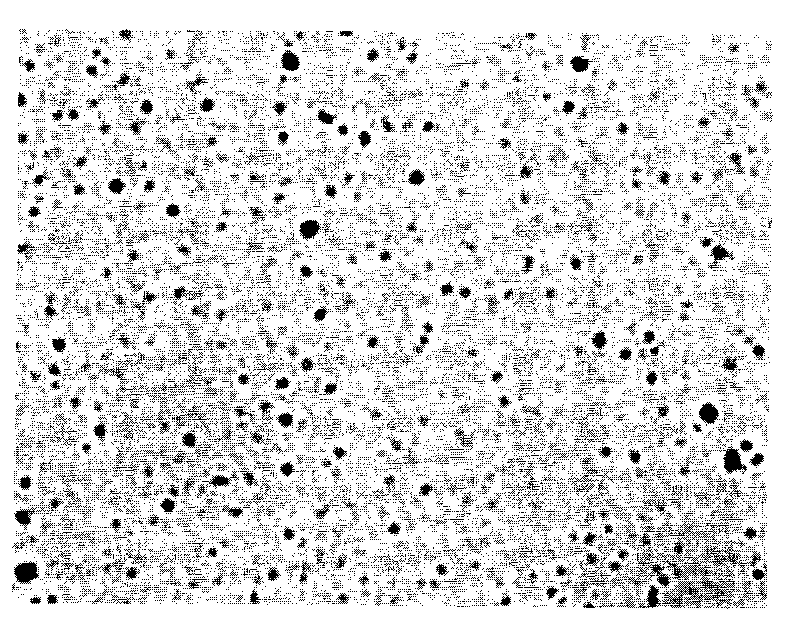

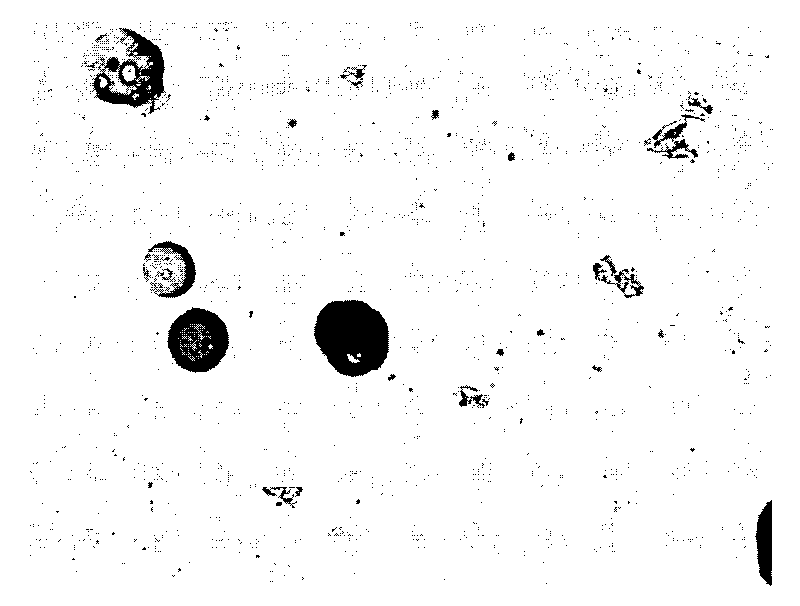

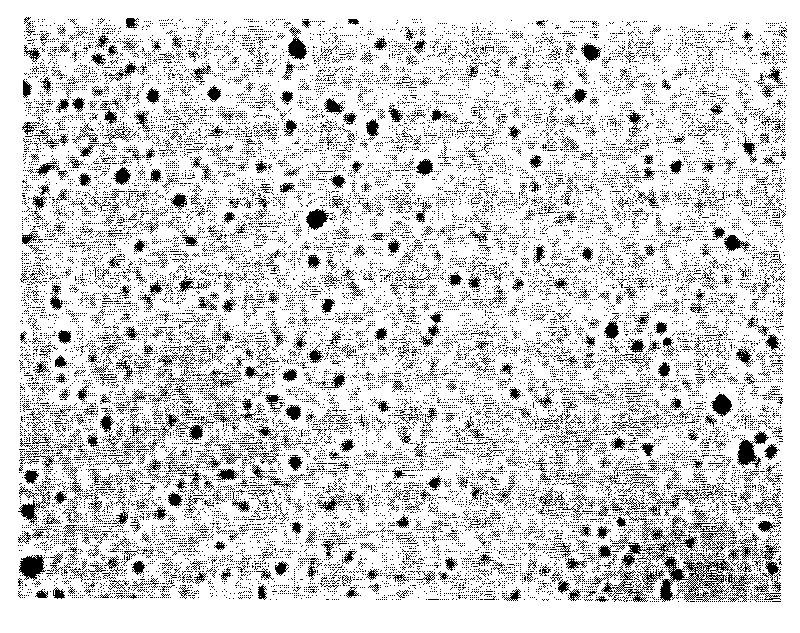

Image

Examples

Embodiment 1

[0038] (1) Camellia oleifera seeds are peeled, dried, crushed, steamed and fried by conventional methods, and the camellia oil is extracted by pressing, and refined tea that meets the national edible first-class camellia oil standard is obtained through alkali refining, water washing, decolorization, deodorization, and winterization Oil;

[0039] (2) Mix maltodextrin and gum arabic in a mass ratio of 3:1, add water to dissolve, make the solid content 20%, and prepare the aqueous solution as wall material solution;

[0040] mixing molecularly distilled monoglyceride and sucrose ester in a mass ratio of 1:1 to prepare a mixed emulsifier;

[0041] (3) Add mixed emulsifier in wall material solution, add refined camellia oil after mixing evenly and carry out emulsification;

[0042] Add the mixed emulsifier of molecularly distilled monoglyceride and sucrose ester of 2% wall material weight in the prepared wall material solution, through the high-speed stirring of high-speed homoge...

Embodiment 2

[0054] (1) Camellia oleifera seeds are peeled, dried, crushed, steamed and fried by conventional methods, and the camellia oil is extracted by pressing, and refined tea that meets the national edible first-class camellia oil standard is obtained through alkali refining, water washing, decolorization, deodorization, and winterization Oil;

[0055] (2) Mix maltodextrin and gum arabic in a mass ratio of 1:1, add water to dissolve, make the solid content 20%, and prepare the aqueous solution as wall material solution;

[0056] Mix molecularly distilled monoglyceride and sucrose ester at a mass ratio of 2:1 to prepare an emulsifier

[0057] (3) Add mixed emulsifier in wall material solution, add refined camellia oil after mixing evenly and carry out emulsification;

[0058] Add the mixed emulsifier of 1.5% molecular distillation monoglyceride and sucrose ester in the prepared wall material solution, through the high-speed stirring of high-speed homogenizer, make mix evenly, press ...

Embodiment 3

[0069] (1) Camellia oleifera seeds are peeled, dried, crushed, steamed and fried by conventional methods, and the camellia oil is extracted by pressing, and refined tea that meets the national edible first-class camellia oil standard is obtained through alkali refining, water washing, decolorization, deodorization, and winterization Oil;

[0070] (2) Mix maltodextrin and gum arabic in a mass ratio of 2:1, add water to dissolve, make the solid content 20%, and prepare the aqueous solution as wall material solution;

[0071] mixing molecularly distilled monoglyceride and sucrose ester in a mass ratio of 4:3 to prepare an emulsifier;

[0072] (3) Add mixed emulsifier in wall material solution, add refined camellia oil after mixing evenly and carry out emulsification;

[0073] Add the mixed emulsifier of 3.5% molecular distillation monoglyceride and sucrose ester in the prepared wall material solution, through the high-speed stirring of high-speed homogenizer, make mix evenly, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com