Optical oxygen sensing composite material and preparation method thereof

A composite material and oxygen sensing technology, applied in the field of Eu complex-based optical oxygen sensing composite material and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

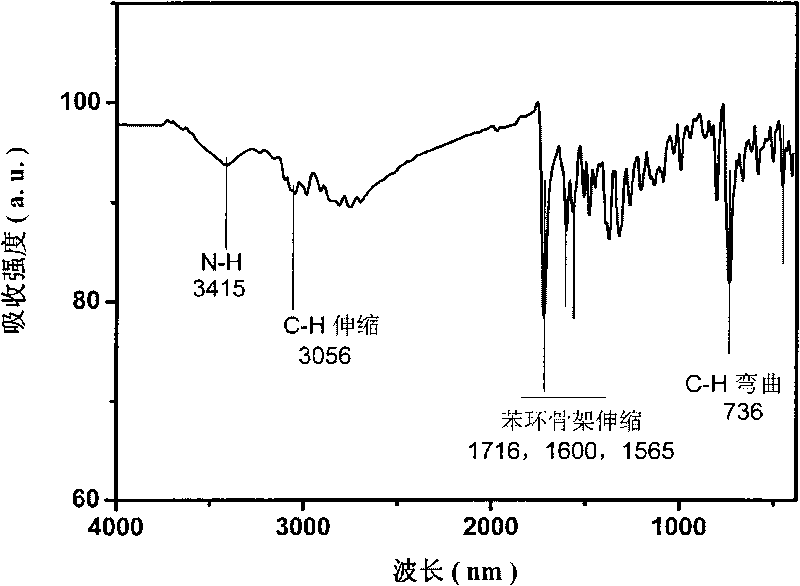

[0050] The preparation of the second ligand 10H-dipyridyl[f,h]indole[3,2-b]quinoline (DPIQ) of the present invention comprises the following steps:

[0051] a. Synthesis of ligand 1,10-o-phenanthroline-5,6-dioxime

[0052] Weigh 0.42 g of 1,10-phenanthroline-5,6-dione, 0.486 g of hydroxylammonium hydrochloride, and 3.00 g of barium carbonate, dissolve them in 30 ml of ethanol, and reflux for 12 hours. After removing ethanol under reduced pressure, add 40ml of 0.2M hydrochloric acid solution to the residue, stir for 30 minutes, filter with suction, wash the filter cake with water, ethanol and ether respectively, and dry under vacuum at 80°C to obtain a yellow solid 1,10-phenanthroline -5,6-dioxime 0.464g (95% yield).

[0053] b. Synthesis of ligand 1,10-o-phenanthroline-5,6-diamine

[0054] Weigh 0.4g of 1,10-phenanthroline-5,6-dioxime and 0.4g of Pd / C (10%), dissolve in 100ml of absolute ethanol, and heat under the protection of nitrogen. At the same time, a mixed solution ...

Embodiment 2

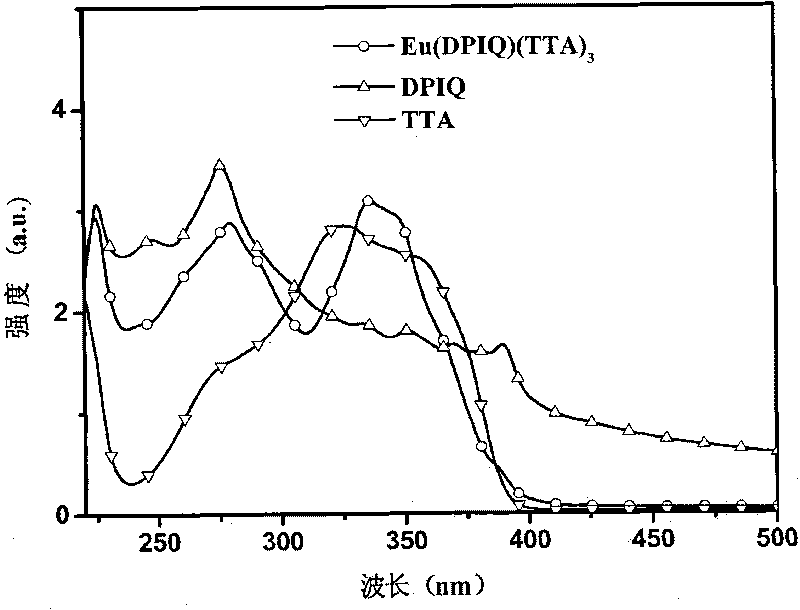

[0058] Eu(DPIQ)(TTA) according to the present invention 3 Preparation of complexes.

[0059] Weigh 0.147 g of the first ligand 4,4,4-trifluoro-1,12-thiophene (TTA) and 0.071 g of the second ligand DPIQ, dissolve in 10 ml of ethanol, and neutralize with NaOH to pH=7. EuCl 3 ·6H 2 O 0.081g was dissolved in 10ml of pure water, poured into the reaction solution, heated and stirred at 60°C for 1 hour, a precipitate formed, filtered and dried to obtain a white solid Eu(DPIQ)(TTA) 3 0.08 g (70% yield).

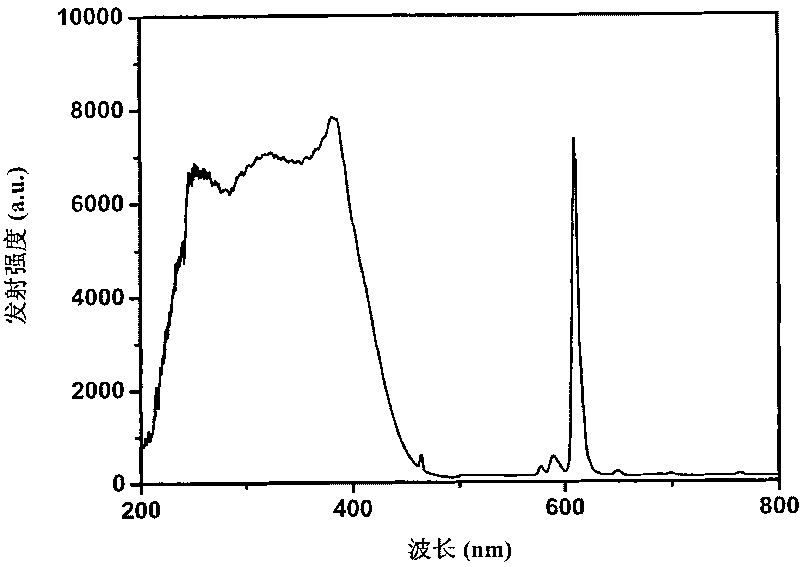

[0060] Eu(DPIQ)(TTA) obtained above was tested under oxygen, nitrogen and air conditions 3 emission spectrum, such as figure 1 shown. Eu(DPIQ)(TTA) 3 The emission spectra in different gas atmospheres show that Eu 3+ Narrowband characteristic emission from Eu 3+ of 5 D. 0 - 7 f 2 The transition emission intensity decreases with the increase of oxygen concentration.

Embodiment 3

[0062]Eu(DPIQ)(TTA) described in the present invention 3 / MCM-41 Optical Oxygen Sensing Composite Fabrication.

[0063] Weigh Eu(DPIQ)(TTA) respectively 3 0.01g, 0.02g, 0.03g, dissolved in 10ml of dichloromethane, added 1g of inorganic mesoporous molecular sieve MCM-41 respectively, stirred at room temperature for 6-12 hours, filtered, washed with dichloromethane until the solution was free from UV light color. Dry at 60°C for 1-2 days, grind and place in a desiccator to obtain yellow powder Eu(DPIQ)(TTA) with doping concentrations of 10mg / g, 20mg / g and 30mg / g respectively 3 / MCM-41.

[0064] The emission spectra of the composite material under different oxygen concentrations under the above-mentioned different doping concentrations were measured, as shown in figure 2 shown. Depend on figure 2 It can be seen that the luminescence intensity of the composite material is greatly quenched with the increase of oxygen concentration. The result was linearly fitted to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com