Catalyst for synthesizing p-aminophenol by hydrogenation reduction of nitrobenzene and preparation method thereof

A technology for p-aminophenol and a catalyst is applied in the field of catalyst for preparing p-aminophenol by catalytic hydrogenation of nitrobenzene and the field of preparation thereof, which can solve the problems of poor PAP selectivity and the like, and achieves improved activity, high catalytic activity and catalytic stability, The effect of high specific surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

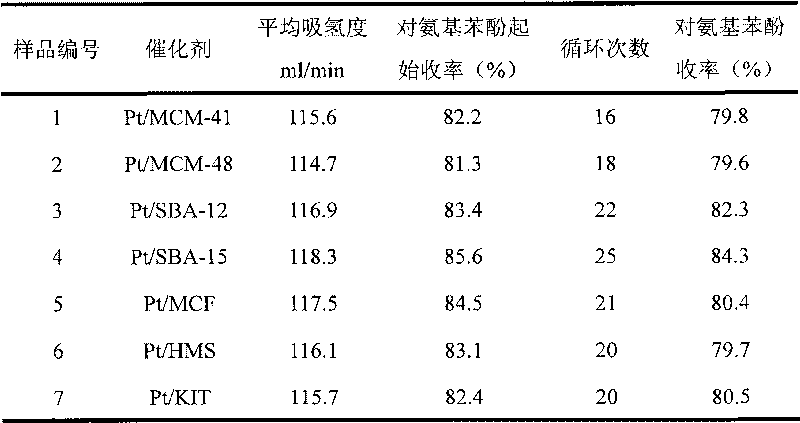

Embodiment 1

[0015] Impregnate the chloroplatinic acid solution with 1% Pt in all silicon mesoporous zeolite MCM-41, MCM-48, SBA-12, SBA-15, MCF, HMS, or KIT-6 for 100-180 minutes , dry at 50-80°C, in an air atmosphere of 350°C, with a space velocity of 9 liters / (hour·gram), roast for 3 hours, switch to nitrogen at room temperature, and then pass through hydrogen for reduction. The reduction conditions are: temperature 450°C, space velocity 25 Liter / (hour·gram) for 3 hours. The hydrogenation reaction process of nitrobenzene is as follows: add catalyst, sulfuric acid, cetyltrimethylammonium bromide, and nitrobenzene into a four-neck flask, close the system, replace the air in the system with hydrogen for 3 times, and the reaction temperature 82°C, connected with a hydrogen meter, record the hydrogen consumption during the reaction, estimate the activity of the catalyst, suck out the supernatant liquid, and obtain the product after two times of steam distillation and acidity adjustment, and ...

Embodiment 2

[0021] Change the active species Ni to test the catalytic activity

[0022] Wet impregnation of 1% Ni chloride solution with all-silicon mesoporous zeolite SBA-15, impregnated for 100-180 minutes, dried at 70°C, and under air atmosphere of 350°C, the space velocity was 8 liters / (hour g ), roasted for 3 hours, switched to nitrogen at room temperature, and then reduced with hydrogen. The reduction conditions were: temperature 450 ° C, space velocity 22 liters / (hour·gram), and maintained for 3 hours. The hydrogenation reaction process of nitrobenzene is as follows: add catalyst, sulfuric acid, cetyltrimethylammonium bromide, and nitrobenzene into a four-neck flask, close the system, replace the air in the system with hydrogen for 3 times, and the reaction temperature 80°C, connected with a hydrogen meter, record the consumption of hydrogen during the reaction, estimate the activity of the catalyst, suck out the supernatant, and obtain the product after two times of steam distilla...

Embodiment 3

[0024] Changing Surfactants to Test Catalytic Activity for OP-10

[0025] Wet impregnation of all-silicon mesoporous zeolite SBA-15 with a chloroplatinic acid solution of 1% measured Pt, impregnated for 100-180 minutes, dried at 70°C, and under an air atmosphere of 350°C, the space velocity was 8 liters / (hour g ), roasted for 3 hours, switched to nitrogen at room temperature, and then reduced with hydrogen. The reduction conditions were: temperature 450 ° C, space velocity 22 liters / (hour·gram), and maintained for 3 hours. The hydrogenation reaction process of nitrobenzene is as follows: add the catalyst, sulfuric acid, OP-10, and nitrobenzene into the four-necked bottle, close the system, replace the air in the system with hydrogen for 3 times, the reaction temperature is 82 ° C, and the hydrogen meter Connected, record the consumption of hydrogen in the reaction process, estimate the activity of the catalyst, suck out the supernatant, and obtain the product through two steam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com