Aniline-2,4-diaminophenol copolymer, preparation method and application thereof in removing chromium ions in water body

A technology of diaminophenol and diaminophenol hydrochloride, which is applied in the field of copolymers, can solve the problems of serious regeneration loss, small adsorption capacity, and high price, and achieve the advantages of less dosage, convenient adsorption operation, and stable properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

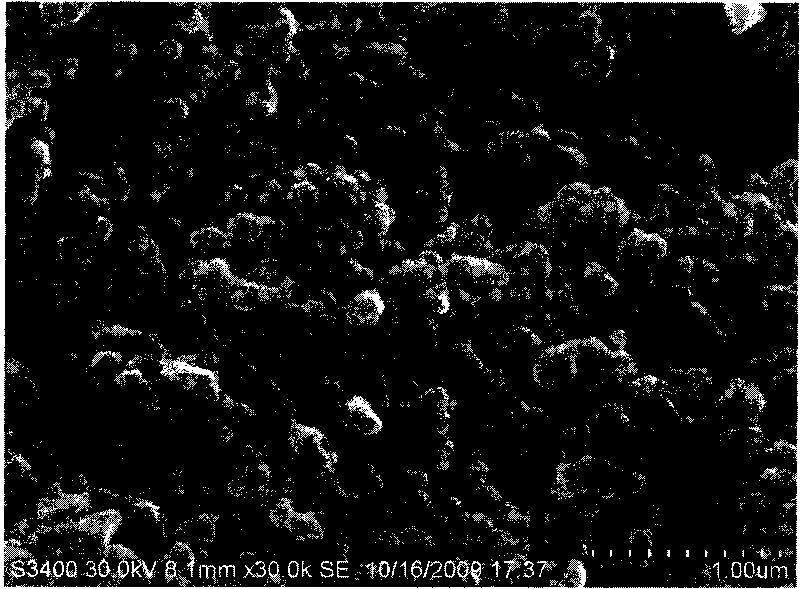

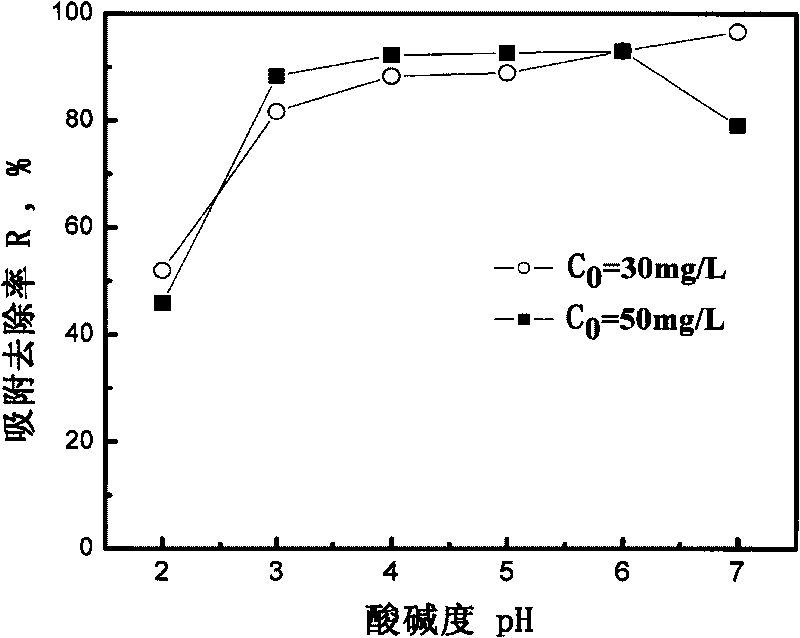

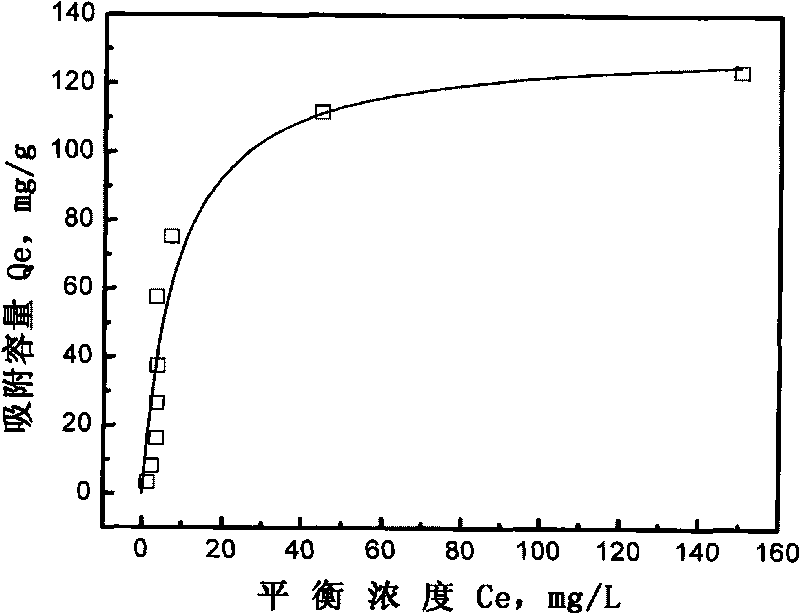

Image

Examples

Embodiment 1

[0017] 1) Dissolve aniline monomer and sulfuric acid in deionized water, add 2,4-diaminophenol hydrochloride under stirring condition, wherein the molar ratio of aniline, sulfuric acid and 2,4-diaminophenol hydrochloride is 25: 62.5:1;

[0018] 2) Ammonium persulfate and sulfuric acid are made into an aqueous solution, wherein the molar ratio of ammonium persulfate to sulfuric acid is 0.56: 1, so that the molar ratio of ammonium persulfate and the aniline monomer in the solution obtained in step 1) is 1.4: 1;

[0019] 3) Slowly add an equal volume of ammonium persulfate and sulfuric acid solution to the reaction solution prepared in the above step 1), stir magnetically, and react for 8 hours;

[0020] 4) The obtained reactant is first washed with dilute sulfuric acid, suction filtered until the filtrate is colorless, and then rinsed several times with deionized water;

[0021] 5) The solid matter obtained in the above step 4) was dried in a vacuum oven at 102° C. for 10 h to ...

Embodiment 2

[0024] 1) Dissolve aniline monomer and sulfuric acid in deionized water, add 2,4-diaminophenol hydrochloride under stirring condition, wherein the molar ratio of aniline, sulfuric acid and 2,4-diaminophenol hydrochloride is 100: 250:1;

[0025] 2) Ammonium persulfate and sulfuric acid are made into an aqueous solution, wherein the molar ratio of ammonium persulfate to sulfuric acid is 0.56: 1, so that the molar ratio of ammonium persulfate and the aniline monomer in the solution obtained in step 1) is 1: 1;

[0026] 3) Slowly add an equal volume of ammonium persulfate and sulfuric acid solution to the reaction solution prepared in the above step 1), stir magnetically, and react for 3 hours;

[0027] 4) The obtained reactant is first washed with dilute sulfuric acid, suction filtered until the filtrate is colorless, and then rinsed several times with deionized water;

[0028] 5) The solid matter obtained in the above step 4) was dried in a vacuum oven at 90° C. for 10 h to obt...

Embodiment 3

[0030] 1) Dissolve aniline monomer and sulfuric acid in deionized water, add 2,4-diaminophenol hydrochloride under stirring condition, wherein the molar ratio of aniline, sulfuric acid and 2,4-diaminophenol hydrochloride is 20: 50:1;

[0031] 2) Ammonium persulfate and sulfuric acid are made into an aqueous solution, wherein the molar ratio of ammonium persulfate to sulfuric acid is 0.56: 1, so that the molar ratio of ammonium persulfate and the aniline monomer in the solution obtained in step 1) is 2: 1;

[0032] 3) Slowly add an equal volume of ammonium persulfate and sulfuric acid solution to the reaction solution prepared in the above step 1), stir magnetically, and react for 12 hours;

[0033] 4) The obtained reactant is first washed with dilute sulfuric acid, suction filtered until the filtrate is colorless, and then rinsed several times with deionized water;

[0034] 5) The solid matter obtained in the above step 4) was dried in a vacuum oven at 110° C. for 10 h to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com