Reduction-sensitive amphiphilic block copolymer and micelle thereof

An amphiphilic block and sensitive technology, which is applied in the direction of drug combination, organic active ingredients, medical preparations of non-active ingredients, etc., to achieve the effect of high encapsulation efficiency and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Synthetic Copolymer Example 1: First, 4,4'-Azobis (4-cyanovaleric acid) (4,4'-Azobis (4-cyanovaleric acid)) and polyethylene glycol 5000 with a methoxy group at one end ( mPEG5000) reaction to prepare 4,4'-azobis (4-cyanovaleric acid) methoxypolyethylene glycol ester macromolecular free radical initiator (PEG 2 -ABCPA) [Neradovic D, vanNostrum CF, Hennink WE. Thermoresponsive polymeric micelles with controlled instability based on hydrolytically sensitive N-isopropylacrylamide copolymers, MACROMOLECULES, 2001, 34(22), 7589-7591]. Polyethylene glycol methacrylate (PEG-MEMA, Mn~300, CAS number: 26915-72-0) hydrophilic monomer 0.40g, tert-butoxycarbonyl cystamine methacrylamide (Boc-Cyst- MAAm) hydrophobic monomer 0.64g and macromolecular initiator PEG 2 - ABCPA 0.25g were dissolved together in 6mL DMF. After vacuuming and nitrogen protection, after repeated three times, radical polymerization was initiated in an oil bath at 70°C for 7 hours, and precipitated with ether,...

preparation example 7

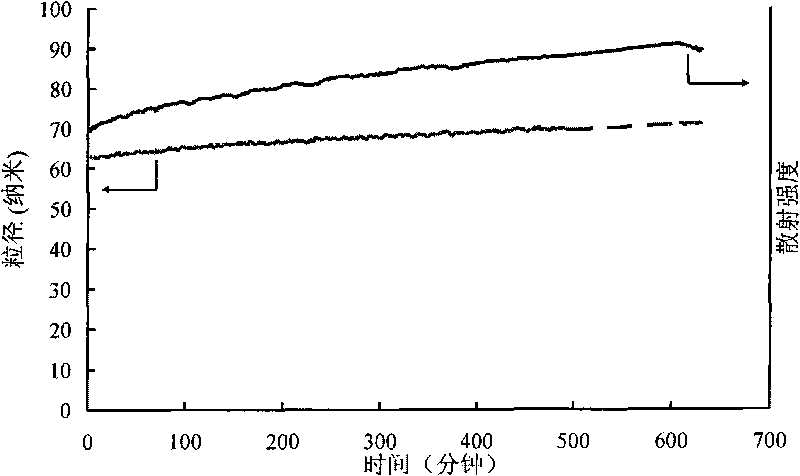

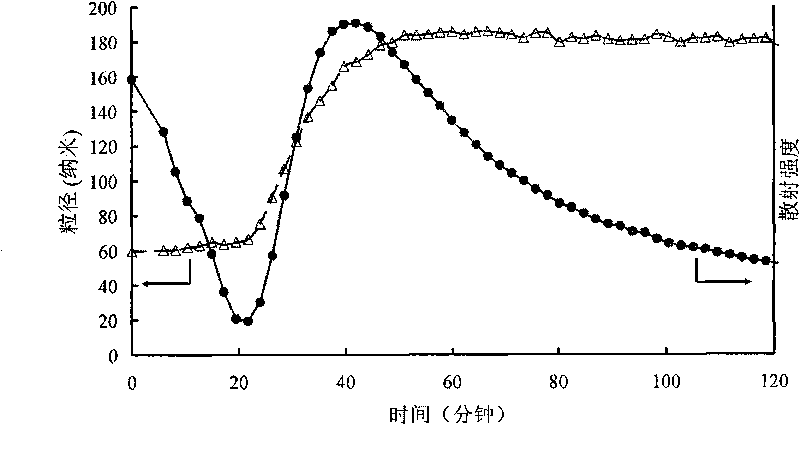

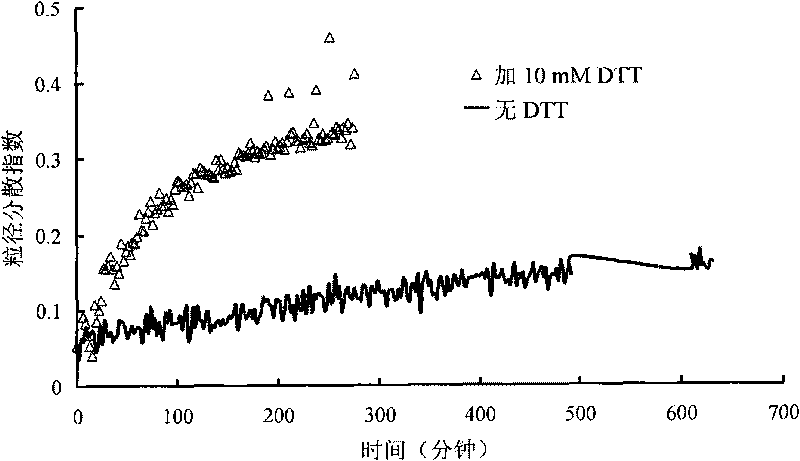

[0029] Micelle Preparation Example 7: Add 10.0 mg of low-temperature water-soluble copolymer PEG-P1 to a sample bottle containing 5.0 mL of sodium phosphate (PBS, 0.15M) buffer solution with pH=7.4, and place in a refrigerator (4°C) Allow it to fully dissolve overnight (2.0mg / mL), then take out the sample bottle from the refrigerator and place it in a water bath at 55°C for one minute, then take it out and cool it to room temperature naturally to obtain stable micellar nanoparticles, which are analyzed by dynamic light scattering (DLS ) The measured average particle diameter is 63nm, and the dispersion index PDI is 0.06. The stability of the micelles was continuously tested by DLS for the particle size and particle size distribution and the change of light scattering intensity at 37°C, see Figure 1a and 1c . At the same time, as a comparison, to 1.0 mL of the same polymer micelles, 20 μL of dithiothreitol (DTT, 0.5 M) was added so that the final concentration of DTT was 10 ...

preparation example 8

[0030] Micelle Preparation Example 8: Dissolve the low-temperature water-insoluble polymer PEG-P2 in ethanol (20 mg / mL), take out 250 μL of the dissolved polymer ethanol solution, add it to 2.25 mL of PBS buffer solution with pH=7.4, and shake well to prepare The stable polymer micellar nanoparticles containing 10% ethanol were obtained, and the polymer concentration was 2.0 mg / mL. The average particle diameter measured by dynamic light scattering (DLS) is 70nm, and the dispersion index PDI is 0.02.

[0031] Micellar drug loading example 9: For the micelle drug loading process of soluble copolymer PEG-P1 in low temperature water, first dissolve paclitaxel in ethanol to make 20 mg / mL paclitaxel ethanol mother solution, and then take a certain amount (for sample A , 20 μL, for sample B, 30 μL, for sample C, 40 μL; for sample D, 70 μL) was diluted to 0.20 mL with ethanol; polymer PEG-P1 was dissolved in PBS buffer solution (2.2 mg / mL) at pH=7.4 , placed overnight in the refriger...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com