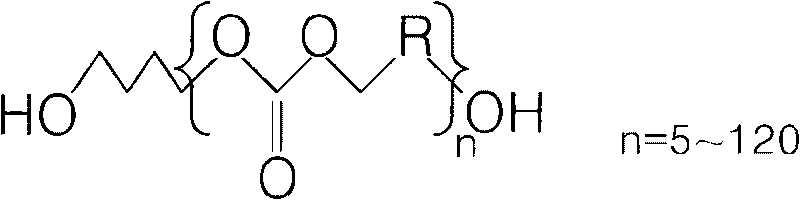

Poly(alkene carbonate) diol-polybutylene succinate copolymer and preparation method thereof

A technology of polybutylene succinate and polybutylene succinate, applied in the field of preparation of aliphatic polybutylene carbonate diol-polybutylene succinate copolymer, the copolyester , can solve problems such as brittleness, and achieve the effect of simplifying the process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] First, a total of 1000 g of 1,4-butanediol and succinic acid with a molar ratio of 1.35:1 were added to a stainless steel reaction kettle, then 0.1 g of stannous chloride was added, and the temperature was raised to 180° C. under the protection of nitrogen, and the esterification 5 hours; evacuate to remove unreacted butanediol, add 0.1 g of titanium tetraisopropoxide, and react for 8 hours at 180° C. and 16 Pa of vacuum to obtain polybutylene succinate oligomer.

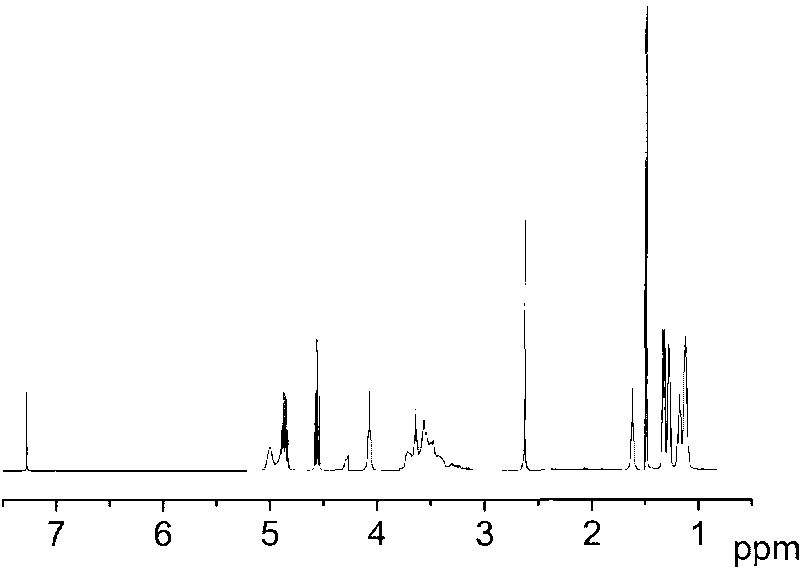

[0021] The polyethylene carbonate diol and polybutylene succinate oligomer that total amount is 1000g is added in the stainless steel reactor, the polyethylene carbonate diol that adds and polybutylene succinate oligomer The mass ratio of the compound is 1: 1000; then add 200g of zinc acetate to carry out the melt co-condensation reaction, the reaction temperature is 210°C, and react for 2 hours under the condition of 300Pa to obtain polyethylene carbonate diol-polybutylene succinate ester polymer. The NMR s...

Embodiment 2

[0023] First, a total of 1000 g of 1,4-butanediol and succinic acid with a molar ratio of 1.35:1 were added to a stainless steel reaction kettle, then 0.1 g of stannous chloride was added, and the temperature was raised to 220° C. under the protection of nitrogen for esterification. 4 hours; evacuate to remove unreacted butanediol, add 0.1 g of titanium tetraisopropoxide, and react for 6 hours at 220° C. and 15 Pa of vacuum to obtain a polybutylene succinate oligomer.

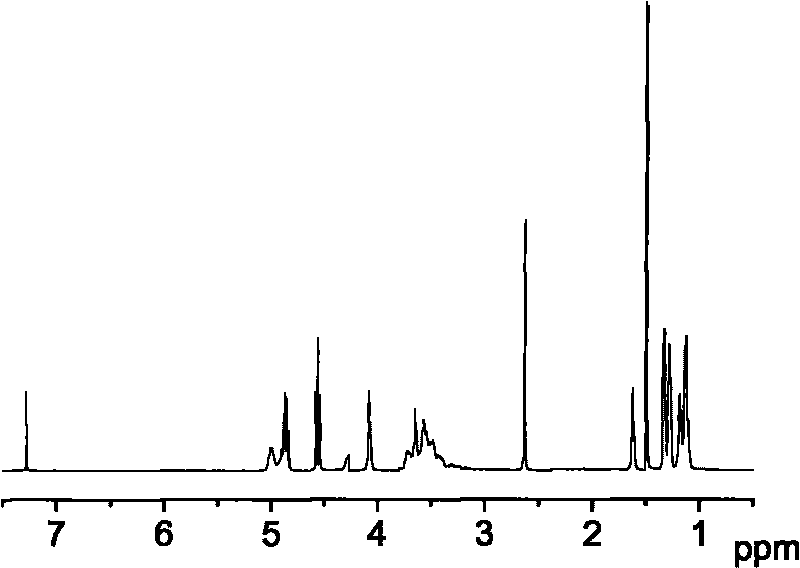

[0024] The polypropylene carbonate diol and polybutylene succinate oligomer that total amount is 1000g is added in the stainless steel reactor, the polypropylene carbonate diol that adds and polybutylene succinate oligomer The mass ratio of the compound is 1: 500; add 0.1g methanesulfonic acid again, carry out melt polycondensation reaction, reaction temperature is 200 ℃, react under 200Pa condition for 10 hours to obtain polypropylene carbonate diol-polybutylene succinate Glycol ester polymer.

Embodiment 3

[0026] First, a total of 1000 g of 1,4-butanediol and succinic acid with a molar ratio of 1.35:1 were added to a stainless steel reaction kettle, and then 0.5 g of stannous chloride was added, and the temperature was raised to 200° C. under the protection of nitrogen, and the esterification 3 hours; vacuumize to remove unreacted butanediol, add 0.5g titanium tetraisopropoxide, and react for 5 hours at 190°C and 16Pa vacuum conditions to obtain polybutylene succinate oligomer;

[0027] A total amount of polybutylene carbonate diol and polybutylene succinate oligomer that is 1000g is added in the stainless steel reactor, the polybutylene carbonate diol that adds and polybutylene succinate oligomer The mass ratio is 1:100; then add 100g of tetrabutyl titanate to carry out melt co-condensation reaction, the reaction temperature is 180°C, and react under 100Pa for 20 hours to obtain polybutylene carbonate diol-polybutylene succinate ester polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com