Method for separating and purifying biodiesel

A biodiesel, separation and purification technology, applied in the preparation of biofuels, biomaterials, liquid hydrocarbon mixtures, etc., can solve the problems of long production cycle, low recovery rate, pollution, etc., and achieves low equipment cost and energy consumption. Simple process and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

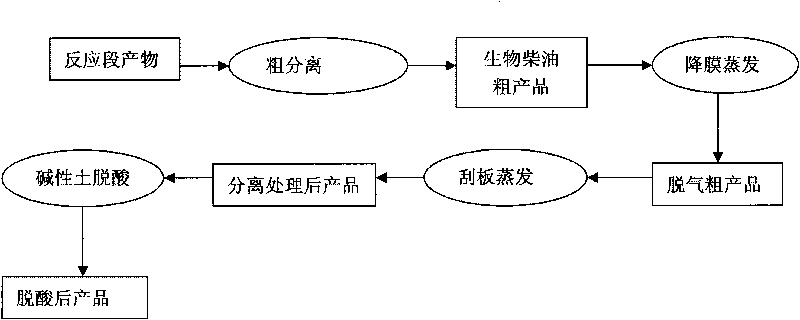

[0071] Example 1. Separation and purification of biodiesel

[0072] The specific method includes the following steps:

[0073] 1) Separation and purification: the crude biodiesel product is degassed and distilled with a thin film evaporator to obtain biodiesel with a methyl ester content of 96%:

[0074] a) Separation and purification object: lipase catalyzes the crude biodiesel product obtained by the esterification reaction of soybean oil (raw oil) with methanol. The by-product glycerin (lower layer) is removed by standing or high-speed centrifugation, and the supernatant is collected (the main component is Crude fatty acid methyl ester) as the object of separation and purification in the next step;

[0075] b) Falling film evaporation: Pass the supernatant obtained in step a) through the falling film evaporator at a vacuum of -0.06MP and a temperature of 120°C for degassing to remove the components at the outlet of the falling film evaporator (in the crude product) Low boiling poi...

Embodiment 2-5

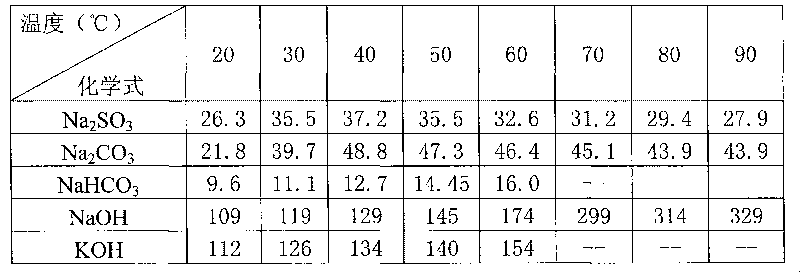

[0090] Example 2-5. Separation and purification of biodiesel using different deacidification agents

[0091] The same method as in Example 1, wherein the dosage of alkaline solution and alkaline soil is changed to obtain purified biodiesel whose acid value meets national standards. The results are shown in Table 3.

[0092] Table 3 Results of Examples 2-5

[0093] Variation factors

Embodiment 6-9

[0094] Example 6-9. Separation and purification of biodiesel from different raw materials

[0095] Such as figure 1 As shown, the method of the present invention is used to separate and purify biodiesel. The specific method is the same as that of Example 1, except that the feedstock oil for producing crude methyl ester is changed. The important indicators of purified biodiesel are shown in Table 4.

[0096] Table 4 Results of Examples 6-9

[0097] project name

Example 6

Example 7

Example 8

Example 9

Feedstock oil for producing crude methyl ester

Acidified oil

Rapeseed oil

Tung oil

Rotating scraper thin film evaporation

Parameters

Vacuum 60Pa

Temperature 160℃

Scraper speed

130rpm

Vacuum 130Pa

Temperature 180℃

Scraper speed

135rpm

Vacuum 70Pa

Temperature 165℃

Scraper speed

140rpm

Vacuum 110Pa

Temperature 175℃

Scraper speed

130rpm

Density (20℃)

842

874

856

847

Kinematic viscosity (40℃)

3.21

3.92

2.78

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com