Anti-sticking soft dope printing adhesive and preparation method

A pigment printing and adhesive technology, applied in dyeing, textiles and papermaking, etc., can solve problems such as poor fastness, achieve super soft hand feeling, excellent washing fastness, and various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Adhesive formulation

[0044] The mass percentage of raw material composition is,

[0045] Ethyl acrylate 31.0%

[0046] Methyl methacrylate 8.50%

[0047] Acrylic 3.40%

[0048] Acrylonitrile 2.60%

[0049] Trimethylolpropane Trimethacrylate 1.30%

[0050] Trimethylisocyanate 1.40%

[0051] Sodium Lauryl Sulfate 0.29%

[0052] Flat Plus 0.89%

[0053] Ammonium persulfate 0.16%

[0055] Sodium bicarbonate 0.08%

[0056] Mercaptan 0.06%

[0057] Deionized water 50.24%

[0058] (2) Preparation method

[0059] A preparation method of anti-sticking soft pigment printing adhesive, the specific steps are:

[0060] (1) Add 1 / 6 of the soft monomer, hard monomer and functional monomer in the raw material components, as well as all emulsifiers and part of deionized water into the reactor, stir and emulsify at room temperature for 30 minutes, raise the temperature to 58°C, add sulfur Alcohols and some initiators;

[0061] (2) Star...

Embodiment 2

[0063] (1) Adhesive formulation

[0064] The mass percentage of raw material composition is,

[0065] Octyl Acrylate 11%

[0066] Butyl Acrylate 8%

[0067] n-Butyl methacrylate 12.47%

[0068] Styrene 6.50%

[0069] Acrylic 4.0%

[0070] Acrylonitrile 2.50%

[0071] Monobutyl itaconate 1.30%

[0072] Trimethylisocyanate 0.80%

[0073] Sodium dodecylbenzenesulfonate 0.32%

[0074] Flat Plus 0.89%

[0076] Hydrogen peroxide 0.16%

[0077] Sodium acetate 0.08%

[0078] Mercaptan 0.06%

[0079] Deionized water 51.84%

[0080] (2) Preparation method

[0081] (1) Add 1 / 8 of the soft monomer, hard monomer and functional monomer in the raw material components, as well as all emulsifiers and part of deionized water into the reactor, stir and emulsify at room temperature for 40 minutes, raise the temperature to 65°C, add sulfur Alcohols and some initiators;

[0082] (2) Start to add the remaining mixed monomers dropwise. After the dropwise ...

Embodiment 3

[0084] The printing paste formula (mass percentage) that adopts the above-mentioned binder formula that prepares to carry out:

[0085] Color paste 3%

[0086] Thickener 3%

[0087] Binder 25%

[0088] Water 69%

[0089] The adhesive synthesized by the invention can replace traditional dye-printed products, and has the advantages of low pollution and convenient use. It has been staked out in many printing companies and achieved good results.

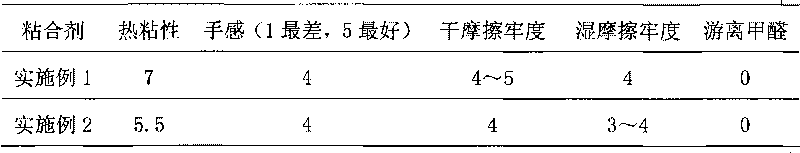

[0090] Adopt general printing process to test described adhesive and obtain following result:

[0091]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com