Lipoprotein capillary coating and the preparation method thereof

A lipoprotein and capillary technology, applied in the field of lipoprotein capillary coating and its preparation, can solve the problems of limited practical application, high dependence on the construction of phospholipid double-layer coating structure, etc., and achieve the effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 physical adsorption method prepares low-density lipoprotein capillary coating

[0021] Weigh 5.0 mg of low-density lipoprotein freeze-dried powder, fully dissolve in 5.0 mL of 25 mmoL phosphate buffer solution (pH=7.4), and prepare a coating solution of 1.0 mg / mL. Pass the coating solution through the pretreated capillary under 10psi pressure for 15 minutes, then seal both ends of the capillary with silicone rubber, fill the capillary with the above-mentioned low-density lipoprotein coating solution, and let it stand at room temperature for 2-4 hours . Fill the coating solution again, seal both ends of the capillary, and let it stand at room temperature for more than 2 hours. After completing the above operations, rinse the capillary with 25mmoL phosphate buffer solution (pH=7.4) for 30 minutes to remove the low-density lipoprotein not bound to the tube wall, seal both ends of the capillary with silicone rubber, and store in a refrigerator at 4°C.

[0022...

Embodiment 2

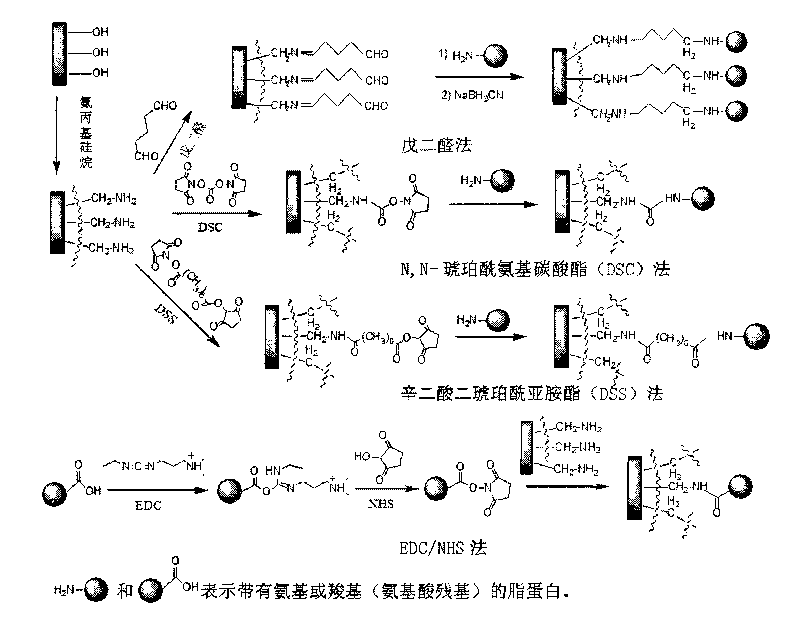

[0023] The preparation of the capillary of embodiment 2 aminopropyl modifications

[0024] Pipette 0.1mL of γ-aminopropyltrimethoxysilane, dissolve it in 1.0mL of water (dilute acetic acid to adjust pH 5)-methanol (2:8, volume ratio) mixed solution, mix well and quickly fill into In the pretreated capillary, seal both ends of the capillary with silicon rubber, and react at room temperature for 2-4 hours. After the reaction is completed, the capillary is washed with methanol and water for 30 minutes each, and then the capillary is aged and dried in an oven at 105-120° C. for more than 2 hours under the protection of high-purity nitrogen. Aminopropyl-modified capillaries were obtained through the above-mentioned treatment steps.

Embodiment 3

[0025] Embodiment 3 uses glutaraldehyde as the chemical bonding method of coupling agent to prepare low-density lipoprotein capillary coating

[0026] Pipette 0.5mL of 50% glutaraldehyde aqueous solution, join in 4.5mL of 25mmoL phosphate buffered saline solution (pH=7.4), after thorough mixing, fill in the aminopropyl group prepared by Example 2 under the pressure of 5psi After modifying the capillary, seal both ends of the capillary with silicone rubber after 1 hour, and let it stand at room temperature for 2-6 hours. Then, 25 mmoL phosphate buffer solution (pH=7.4) was used to flush out the unreacted glutaraldehyde solution to obtain a glutaraldehyde-modified capillary.

[0027] Prepare a 1.0 mg / mL low-density lipoprotein coating solution according to the method described in Example 1, fill the solution into the above-mentioned capillary treated with glutaraldehyde, seal both ends after 30 minutes, and continue the reaction at room temperature 2-4 hours. During this react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com