Method for preparing sodium lignin sulfonate water reducer

The technology of sodium lignosulfonate and water reducing agent is applied in the field of preparing sodium lignosulfonate water reducing agent, can solve the problems of high operating cost, low alkali recovery rate and high benefit, and achieves low cost and high sulfonation degree , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

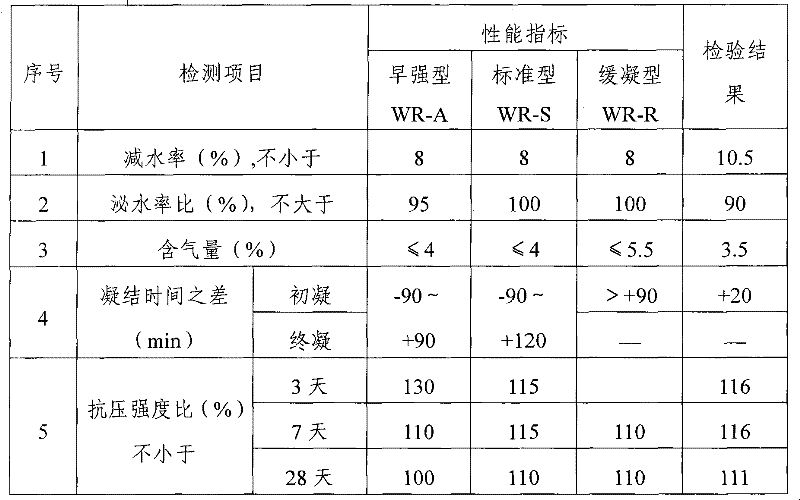

Image

Examples

Embodiment 1

[0036] 1. Raw material and formula:

[0037] Black liquor: 75.7kg

[0038] Formaldehyde: 0.340kg

[0039] Sodium sulfite: 0.340kg

[0040] 2. Process steps and process parameters:

[0041] Be that the coarse filter (material is PP material) of 5 μm with aperture, carry out coarse filtration to black liquor, weight after filtering is 75.7kg, and solid content is 9.54%, and lignin content is 2.0%;

[0042] The coarse filtrate is subjected to ultrafiltration treatment. The pore size of the ultrafiltration membrane is 5000MD, and the material is an alkali-resistant membrane material (polyolefin, American Hyde Energy Company). During ultrafiltration, the inlet pressure is controlled not to exceed 25kgf / cm 2 , differential pressure 1kgf / cm 2 Within the range, the temperature does not exceed 40°C, and the treatment time is 5 hours. After the treatment, the clear liquid is recycled to the alkali boiling process for use. The weight of the concentrated liquid is 12.8kg, of which the...

Embodiment 2

[0046] 1. Raw material and formula:

[0047] Black liquor: 121.765kg

[0048] Formaldehyde: 0.365kg

[0049] Sodium sulfite: 0.365kg

[0050] 2. Process steps and process parameters:

[0051] Use a coarse filter with a pore size of 1-10 μm, made of PP material, to coarsely filter the black liquor. After filtering, the weight is 121.765kg, the solid content is 6.59%, and the lignin content is 1.3%.

[0052] The coarse filtrate is subjected to ultrafiltration treatment. The pore size of the ultrafiltration membrane is 10000MD, and the material is an alkali-resistant membrane material (polyethersulfone, German Meynard company). During ultrafiltration, the inlet pressure is controlled not to exceed 15kgf / cm 2 , differential pressure 2kgf / cm 2 Within the range, the temperature does not exceed 40°C, and the treatment time is 10.72 hours. After the treatment, the clear liquid is recycled to the alkali boiling process for use. The weight of the concentrated liquid is 14.63 kg, of ...

Embodiment 3

[0056] 1. Raw material and formula:

[0057] Black liquor: 122.4kg

[0058] Formaldehyde: 0.519kg

[0059] Sodium sulfite: 0.519kg

[0060] 2. Process steps and process parameters:

[0061] With the coarse filter (material is PP material) that aperture is 1-10 μ m, carry out coarse filtration to black liquor, weight after filtering is 122.4kg, and solid content is 9.79%, and lignin content is 2.2%;

[0062] The coarse filtrate is subjected to ultrafiltration treatment. The pore size of the ultrafiltration membrane is 2000MD, and the material is an alkali-resistant membrane material (the material is polysulfone, American Koch Company). ℃, the treatment time is 10.9h, and the clear liquid after treatment is recycled to the alkali boiling process for use. The weight of the concentrated liquid is 20.2kg, of which the solid content is 31.55%, and the lignin is 11.63%;

[0063] Take 14.865kg of concentrated liquid for sulfonation test, add 519g of formaldehyde, raise the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com