High-performance quantum dot-polymer fluorescent nano composite material and preparation method thereof

A technology of fluorescent nano-composite materials, applied in the field of high-performance quantum dot-polymer fluorescent nanocomposite materials and their preparation, can solve the problems of loss of luminescent properties and no reports of quantum dots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

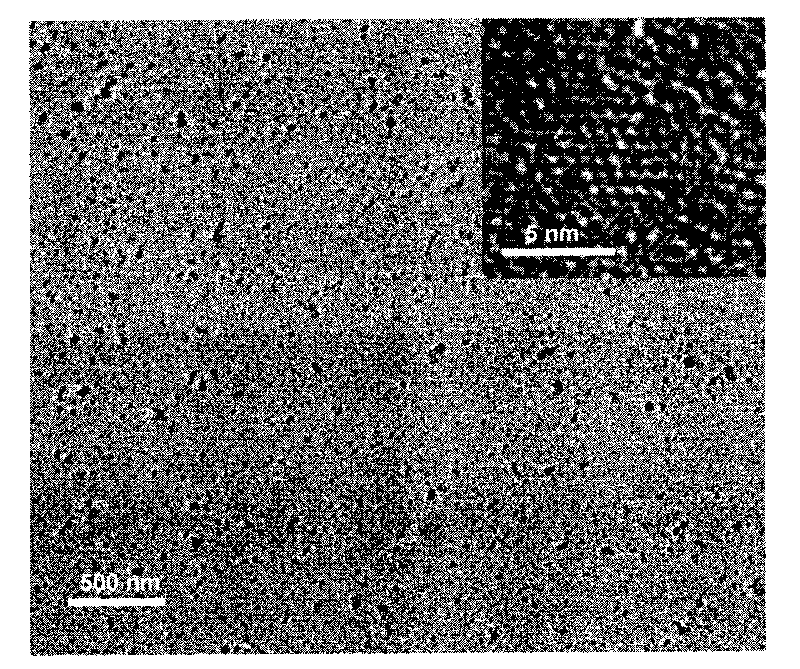

[0017] After dissolving 1g of polymethyl methacrylate with ethyl acetate, add 0.08g of silica hybrid with a particle size of 12 nm modified with 3-(trimethoxysilyl)propyl methacrylate. The cadmium telluride quantum dots were stirred for 5 hours, and the ethyl acetate was naturally placed to remove ethyl acetate to obtain a cadmium telluride-polymethyl methacrylate nanocomposite material. The transmission electron microscope image of the film is attached figure 1 As shown, 3-(trimethoxysilyl)propyl methacrylate-modified silica hybrid cadmium telluride quantum dots are uniformly dispersed in polymethylmethacrylate, high-resolution transmission electron microscopy It is confirmed that the crystal structure of CdTe quantum dots is well maintained, so the resulting film has both strong transparency and excellent luminescent properties.

Embodiment 2

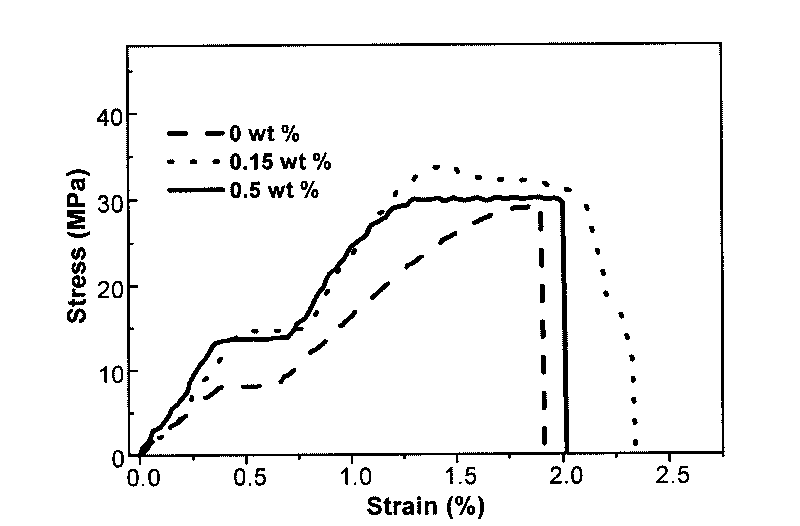

[0019] Heating 1g of polystyrene to 150°C, then adding 0.005g of silicon dioxide hybrid cadmium selenide quantum dots with a particle size of 20 nm modified with propyltriethoxysilane, stirred for 1 hr, and cooled naturally to obtain Cadmium selenide-polystyrene nanocomposites. Its tensile stress-strain curve is attached as figure 2 As shown, compared with pure polystyrene, its Young's modulus increased by 42%, and its elongation at break increased by 6%.

Embodiment 3

[0021] Embodiment 3 is the same as embodiment 2, just the addition of the silicon dioxide hybridized cadmium selenide quantum dots of 20 nanometers is changed into 0.0015g to the particle diameter modified by propyl triethoxysilane, obtains cadmium selenide-poly Styrene nanocomposites. Its tensile stress-strain curve is attached as figure 2 As shown, compared with pure polystyrene, its tensile strength at break increased by 11%, Young's modulus increased by 33%, and elongation at break increased by 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com