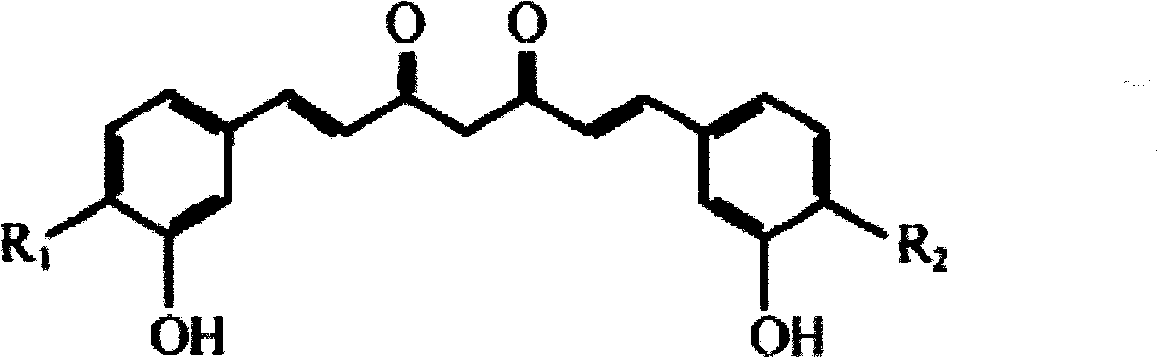

Purification technology of curcumin compound

A technology for curcumin and compounds, applied in the field of purification technology of curcumin compounds, can solve the problems of unsuitable for industrial production, high professional requirements, difficult to control, etc., and achieves a life span that can be reused, shortens extraction time, and avoids high-temperature decomposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Take turmeric and grind it to 20 mesh, take 10kg, put it into an extraction tank, add 100L petroleum ether to reflux for extraction for 2 hours, filter, and recover petroleum ether; add 8 times the volume of sodium salicylate alcohol solution to the residue, ultrasonically extract for 30 minutes, filter, The second extraction solvent and time are all halved, the extracts are combined, the reagents are recovered and concentrated into a paste, and S-8 macroporous resin is added for adsorption. ) elution, while detecting with thin-layer chromatography, collect curcumin, demethoxycurcumin and demethoxycurcumin flow fractions respectively with brown bottles, and reclaim the reagent. Dissolve with a small amount of acetone respectively, quickly add water 3 times the amount of acetone, centrifuge at 10000r / min, discard the supernatant, repeat the operation 3 times, and freeze-dry the precipitate to obtain 138g of curcumin, 27g of demethoxycurcumin, and Dimethoxy curcumin 20g. ...

Embodiment 2

[0044] Take turmeric and grind it to 30 mesh, take 10kg, put it into an extraction tank, add 60L petroleum ether to reflux for extraction for 3 hours, filter, and recover petroleum ether; add 6 times the volume of sodium salicylate alcohol solution to the residue, ultrasonically extract for 45 minutes, filter, For the second extraction, the solvent and time were halved, the extracts were combined, the reagents were recovered and concentrated into a paste, added to DM301 macroporous resin for adsorption, and the impurities were first washed with water, then washed with acetone-2% glacial acetic acid (50:50) Remove, and detect with thin-layer chromatography at the same time, collect curcumin, demethoxycurcumin and demethoxycurcumin fractions respectively with brown bottle, recover reagent. Dissolve with a small amount of acetone respectively, quickly add water with 3 times the amount of acetone, centrifuge at 8000r / min, discard the supernatant, repeat the operation twice, and fre...

Embodiment 3

[0046]Take turmeric and grind it to 60 mesh, take 5kg, put it into an extraction tank, add 40L petroleum ether to reflux for extraction for 1 hour, filter, and recover petroleum ether; add 10 times the volume of sodium salicylate alcohol solution to the residue, ultrasonically extract for 60 minutes, filter, The second extraction solvent and time are all halved, the extracts are combined, the reagents are recovered and concentrated into a paste, and X-5 macroporous resin is added for adsorption. ) elution, while detecting with thin-layer chromatography, collect curcumin, demethoxycurcumin and demethoxycurcumin flow fractions respectively with brown bottles, and reclaim the reagent. Dissolve with a small amount of acetone, quickly add water with 3 times the amount of acetone, centrifuge at 5000r / min, discard the supernatant, repeat the operation 3 times, and freeze-dry the precipitate to obtain 73g of curcumin and 14.1g of demethoxycurcumin, respectively. Dedimethoxycurcumin 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com