Compound bamboo shoot wall breaking enzyme and preparation method of bamboo shoot dietary fiber

A technology of bamboo shoot dietary fiber and wall-breaking enzyme, which is applied in the directions of food preparation, biochemical equipment and methods, enzymes, etc., can solve the problems of low release rate of soluble dietary fiber, harsh process control conditions, complicated preparation process, etc., and achieves good practicality. Value and application prospects, easy control of process conditions, high wall breaking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

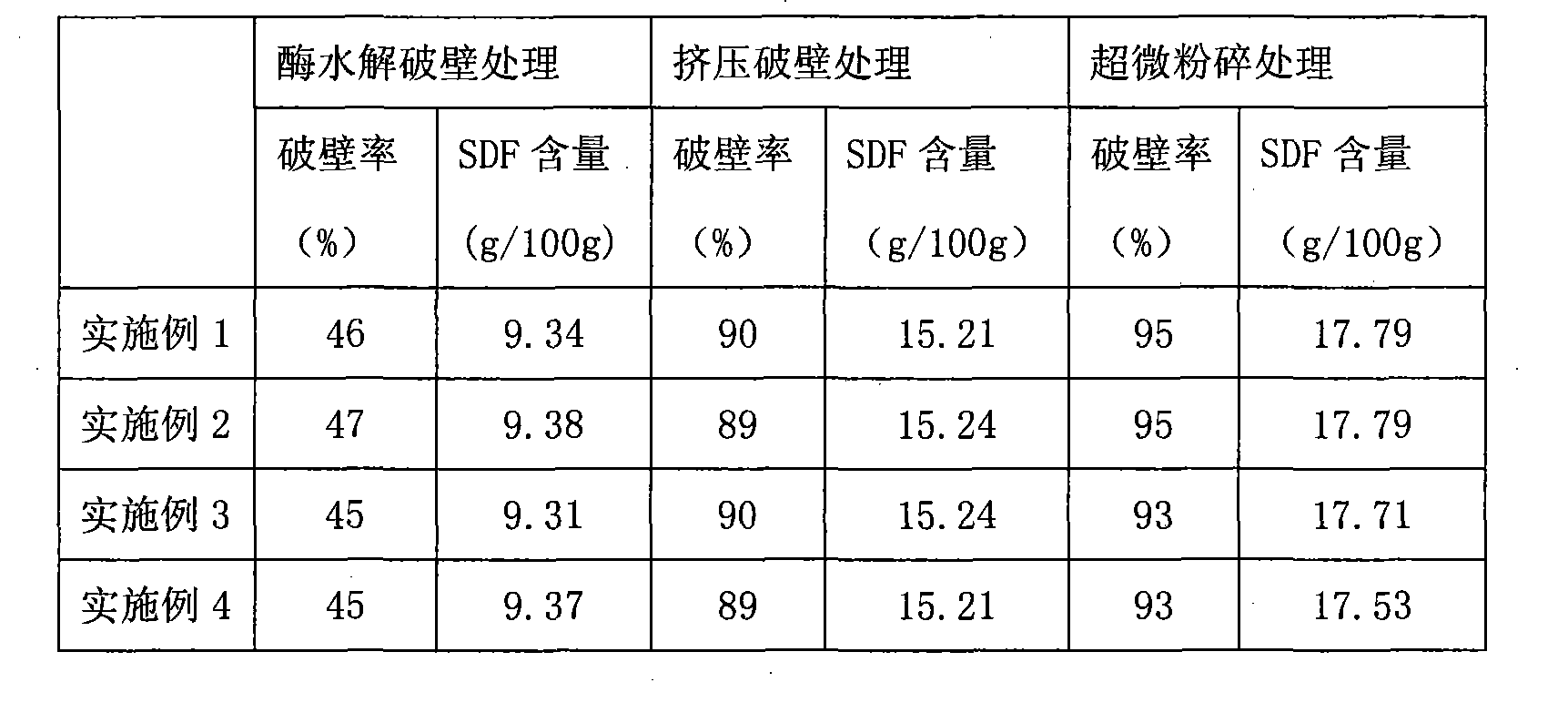

Examples

Embodiment 1

[0048] 1. Prepare bamboo shoot powder

[0049] 1) Take the bamboo shoots and wash them, remove the damaged, uneven, and uneven parts, chop them with a shredder, and place them in a homogenizer for 30 minutes to obtain a fiber homogenate of the bamboo shoots. The rotating speed of the pulp machine is 4500 rpm, and the moisture content of the bamboo shoots is 85.7%;

[0050] 2) Put the bamboo shoot fiber homogenate in a vacuum drying oven (Beijing Grawell Technology Co., Ltd., model DZF6090) to dry, control the drying temperature to 70°C, and dry it until the moisture content is 5% before pulverizing to obtain 40 mesh bamboo shoot powder.

[0051] 2. Enzymatic hydrolysis and wall breaking treatment

[0052] 1) Adding water to the bamboo shoot powder and stirring evenly to obtain a mixed liquid of bamboo shoot powder, the ratio by weight of the bamboo shoot powder to water is 4:1;

[0053] 2) adding a monosodium citrate solution with a concentration of 10% by mass to adjust th...

Embodiment 2

[0073] 1. Prepare bamboo shoot powder

[0074] 1) Take the bamboo shoots and wash them, remove the damaged, uneven, and uneven parts, chop them with a shredder, and place them in a homogenizer for 60 minutes to obtain a fiber homogenate of the bamboo shoots. The rotating speed of the pulp machine is 3000 rpm, and the moisture content of the bamboo shoots is 83.5%;

[0075] 2) The bamboo shoot fiber homogenate is placed in a vacuum drying oven for drying, the drying temperature is controlled at 80° C., and it is dried until the moisture content is 6%, and then pulverized to obtain 60-mesh bamboo shoot powder.

[0076] 2. Enzymatic hydrolysis and wall breaking treatment

[0077] 1) Adding water to the bamboo shoot powder and stirring evenly to obtain a mixed liquid of bamboo shoot powder, the ratio by weight of the bamboo shoot powder to water is 4:1;

[0078] 2) adding a lactic acid solution with a mass percent concentration of 15% to adjust the pH of the bamboo shoot powder ...

Embodiment 3

[0093] 1. Prepare bamboo shoot powder

[0094] 1) Take the bamboo shoots and wash them, remove the damaged, uneven, and uneven parts, chop them with a shredder, and place them in a homogenizer for 20 minutes to obtain a fiber homogenate of the bamboo shoots. The rotating speed of the pulp machine is 5000 rpm, and the moisture content of the bamboo shoots is 85.0%;

[0095] 2) The bamboo shoot fiber homogenate is placed in a vacuum drying oven for drying, the drying temperature is controlled at 80° C., dried to a moisture content of 5%, and then pulverized to obtain 50 mesh of bamboo shoot powder.

[0096] 2. Enzymatic hydrolysis and wall breaking treatment

[0097] 1) Adding water to the bamboo shoot powder and stirring evenly to obtain a mixed liquid of bamboo shoot powder, the ratio by weight of the bamboo shoot powder to water is 4:1;

[0098] 2) adding a malic acid solution with a concentration of 20% by mass to adjust the pH of the bamboo shoot powder mixture to 6.5;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Broken rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com