Solar energy and recycled water dual-heat-resource heat pump sludge drying system

A sludge drying and solar energy technology, which is applied in heat recovery system, dewatering/drying/concentrating sludge treatment, energy and wastewater treatment, etc., can solve problems affecting sustainable development, shortage of land resources, and high sludge moisture content, Achieve the effect of improving production environment, expanding contact area and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

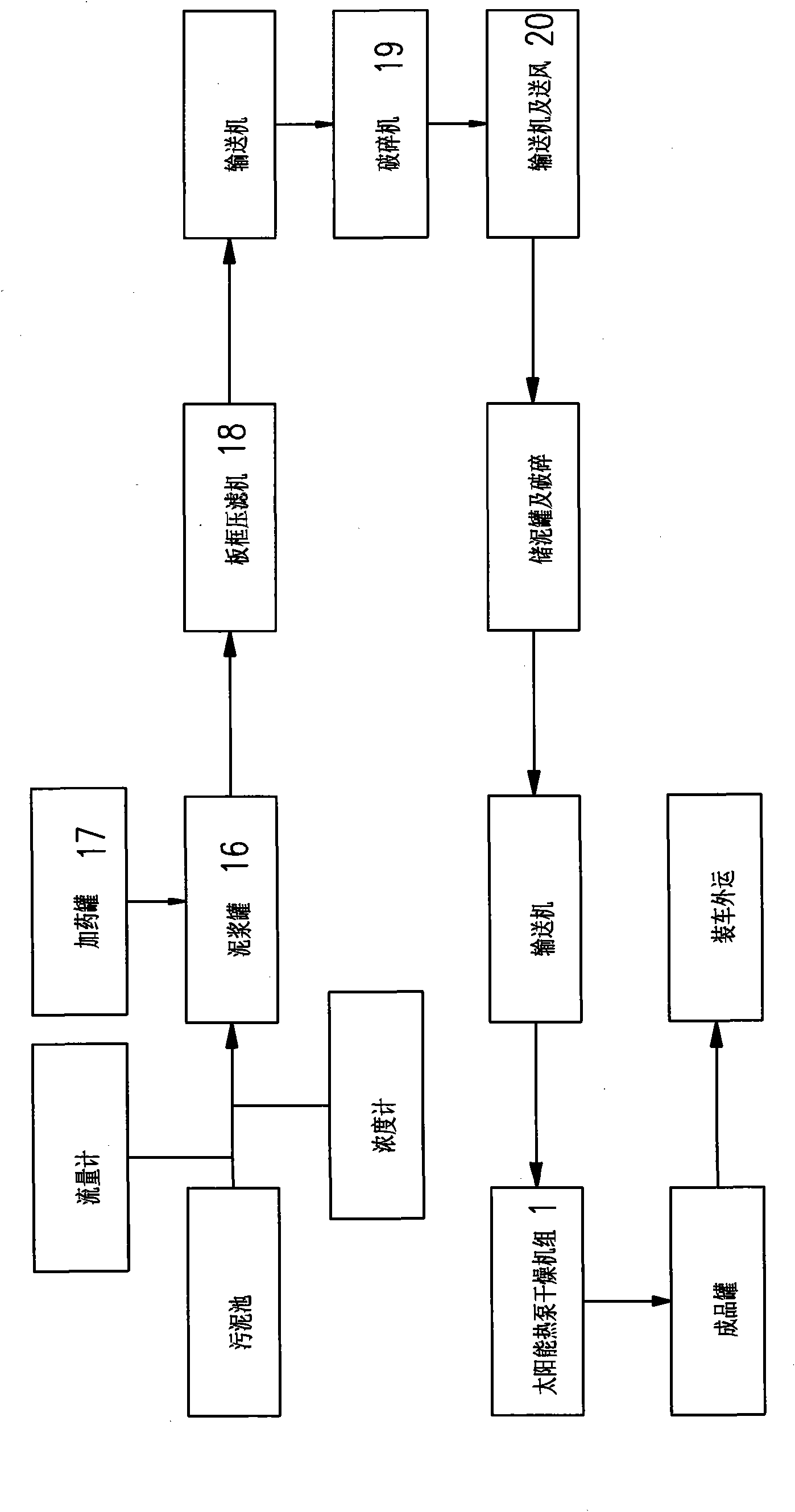

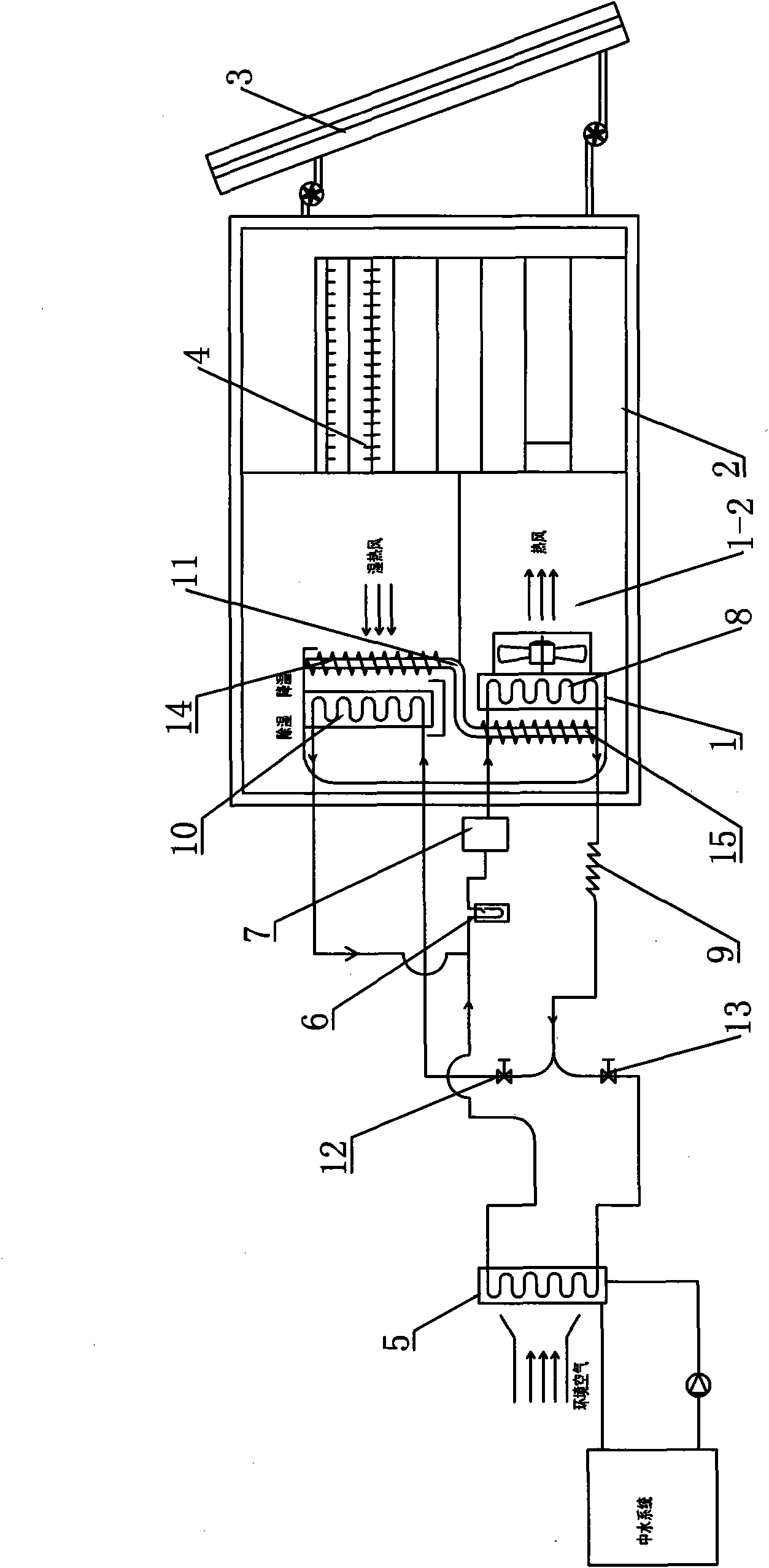

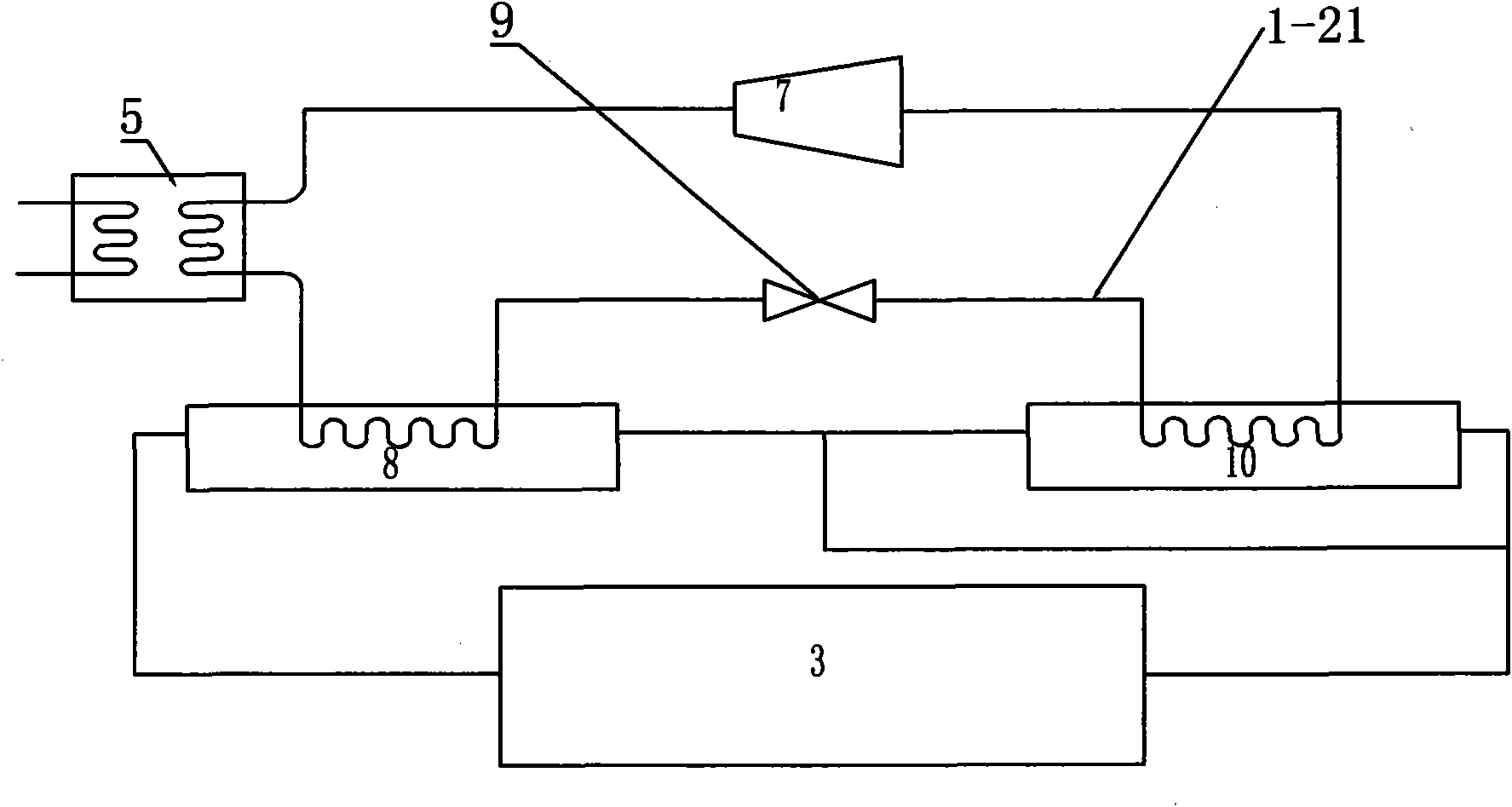

[0022] Such as figure 1 As shown, a solar energy reclaimed water dual heat source heat pump sludge drying system of the present invention is composed of fully automatic plate and frame filter press equipment 21, crushing equipment and solar energy and reclaimed water dual heat source heat pump drying equipment, and specifically includes a mud tank 16 , dosing tank 17, feeding pump, automatic plate and frame filter press 18, crusher 19, air supply system 20, solar collector 3, high voltage electric field 4, drying and conveying equipment, multi-stage crushing device, electric control system , hot air circulation pipeline system, reclaimed water tower, heat pump heating device, heat preservation facility, safety device, mud tank 16 extracts quantitative mud from the sludge tank, adds medicine to it from dosing tank 17, and then transports it to the fully automatic plate and frame press The filter 18 is crushed by the crusher 19 after pressure filtration, dried by the air supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com