Collagen polypeptide, preparation method and application thereof

A collagen polypeptide and keratinase technology, applied in the field of enzyme catalysis, can solve problems such as incomplete hydrolysis, fishy smell, and difficulty in removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

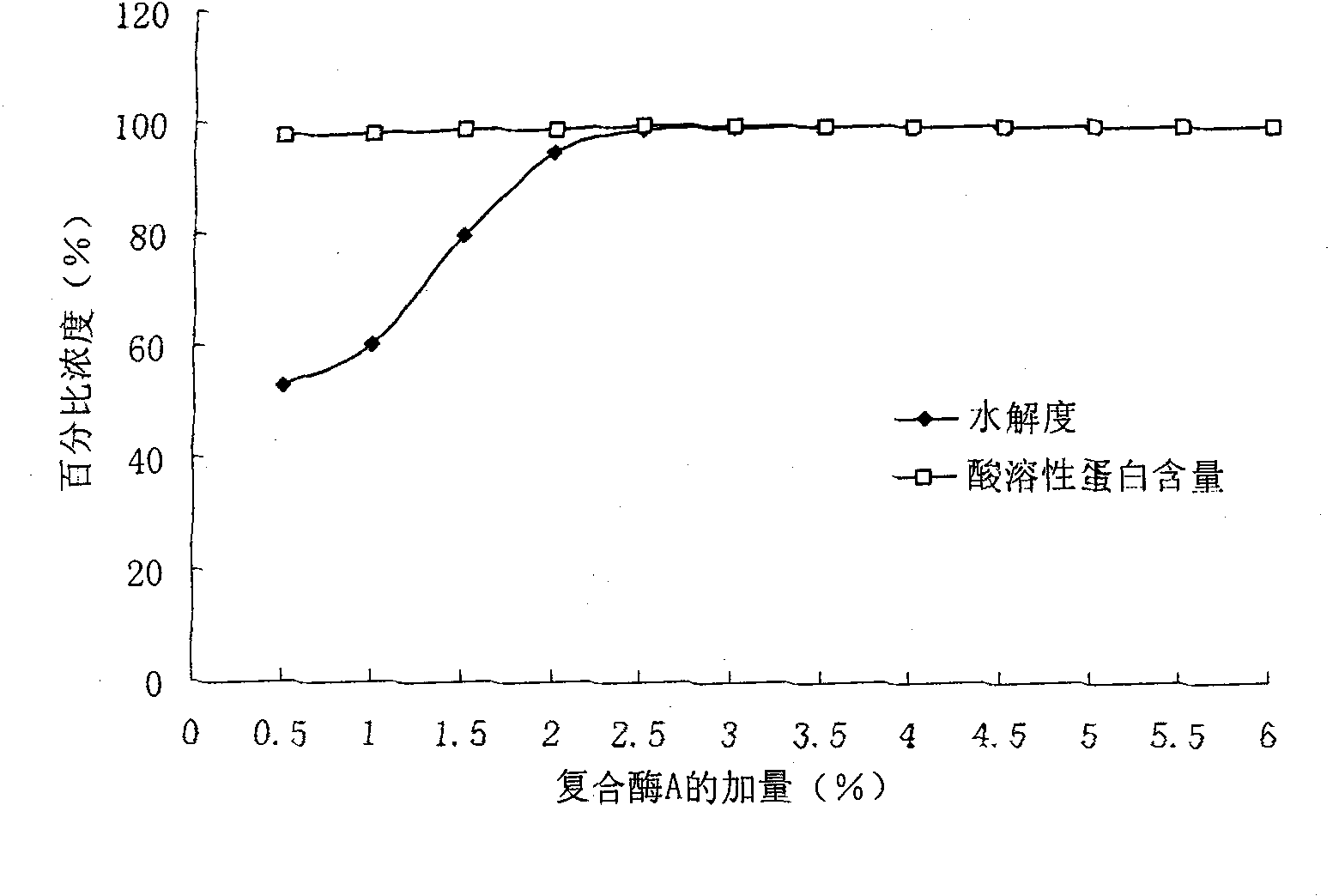

[0067] The invention provides a preparation method of collagen polypeptide, which comprises the steps of: adding compound enzyme A to hydrolyze the raw material after pretreatment, after the hydrolyzate is subjected to microfiltration, desalting and decolorizing through ion exchange resin, and finally making collagen polypeptide .

[0068] In a preferred embodiment of the present invention, based on the total weight of solids, the compound enzyme A is added in an amount of 2-5w / w% of the solids content.

[0069] In a preferred embodiment of the present invention, the hydrolysis used is under the conditions of 50°C-60°C and pH 9-10 for 6-10 hours.

[0070] In another preferred embodiment of the present invention, the raw material of the method for preparing collagen polypeptide is animal skin, taking fish skin or pig skin as an example, comprising the following steps:

[0071] 1) Raw material pretreatment Ⅰ: cleaning and degreasing the fish skin or dehaired pig skin to remove ...

Embodiment 1

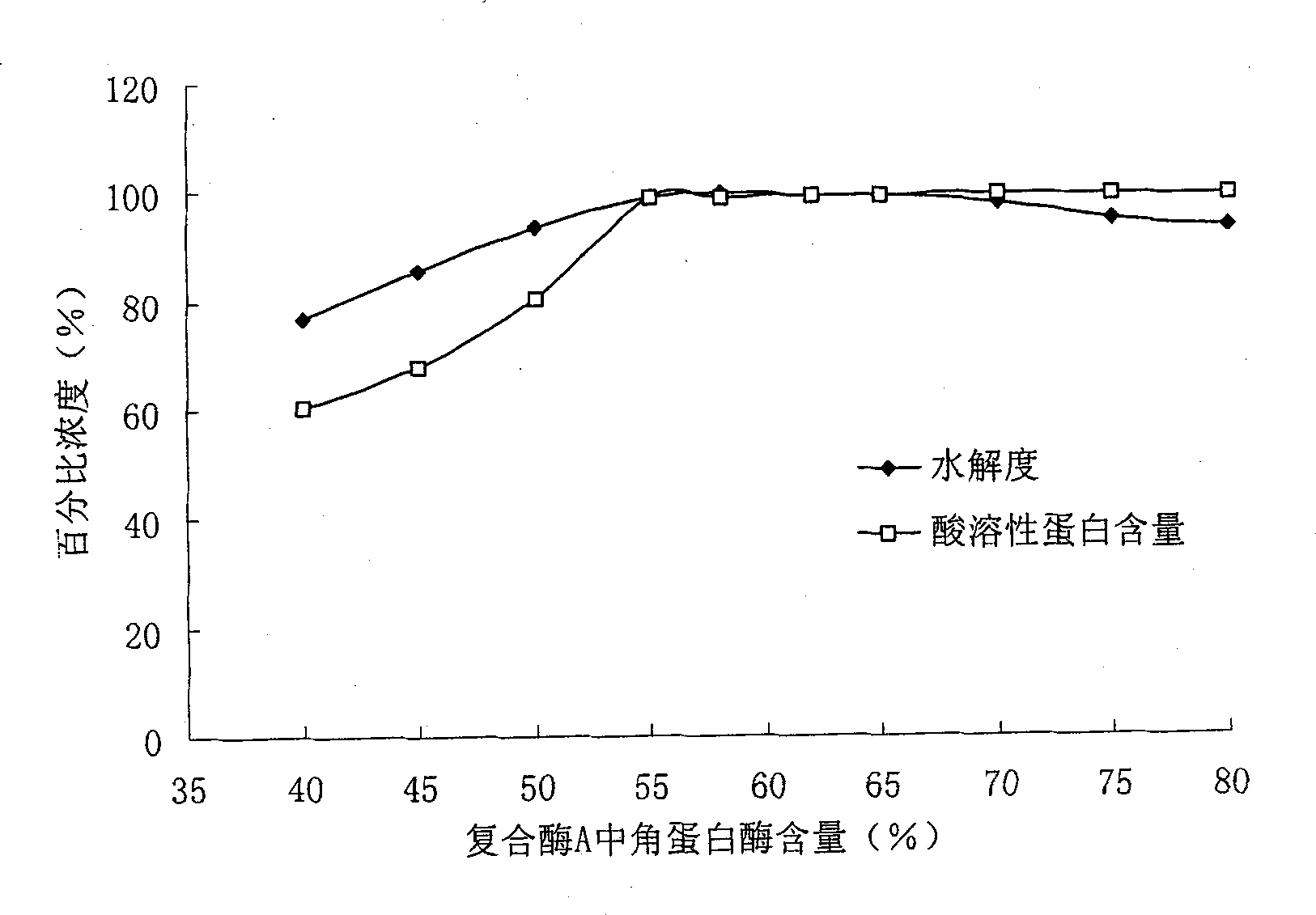

[0116] Hydrolysis of Collagen by Compound Enzyme A

[0117] In the range of 40-80w / w%, gradually adjust the percentage concentration of keratinase in the complex enzyme A, then according to step 1) to step 4) described in Example 2 (1), or Example 2 (2) Step 1) to step 3) described in, or step 1) to step 4) described in embodiment 2 (3) implements compound enzyme A to the hydrolysis of collagen (the amount of compound enzyme A is according to 3w of raw material amount / w% added), after hydrolysis finishes, get enzymolysis solution 5ml12000rpm centrifugal 5 minutes, get supernatant and measure soluble protein content with Folin-phenol method, and calculate degree of hydrolysis DH according to following formula:

[0118] DH ( % ) = ( N 2 - N 1 ) ...

Embodiment 2

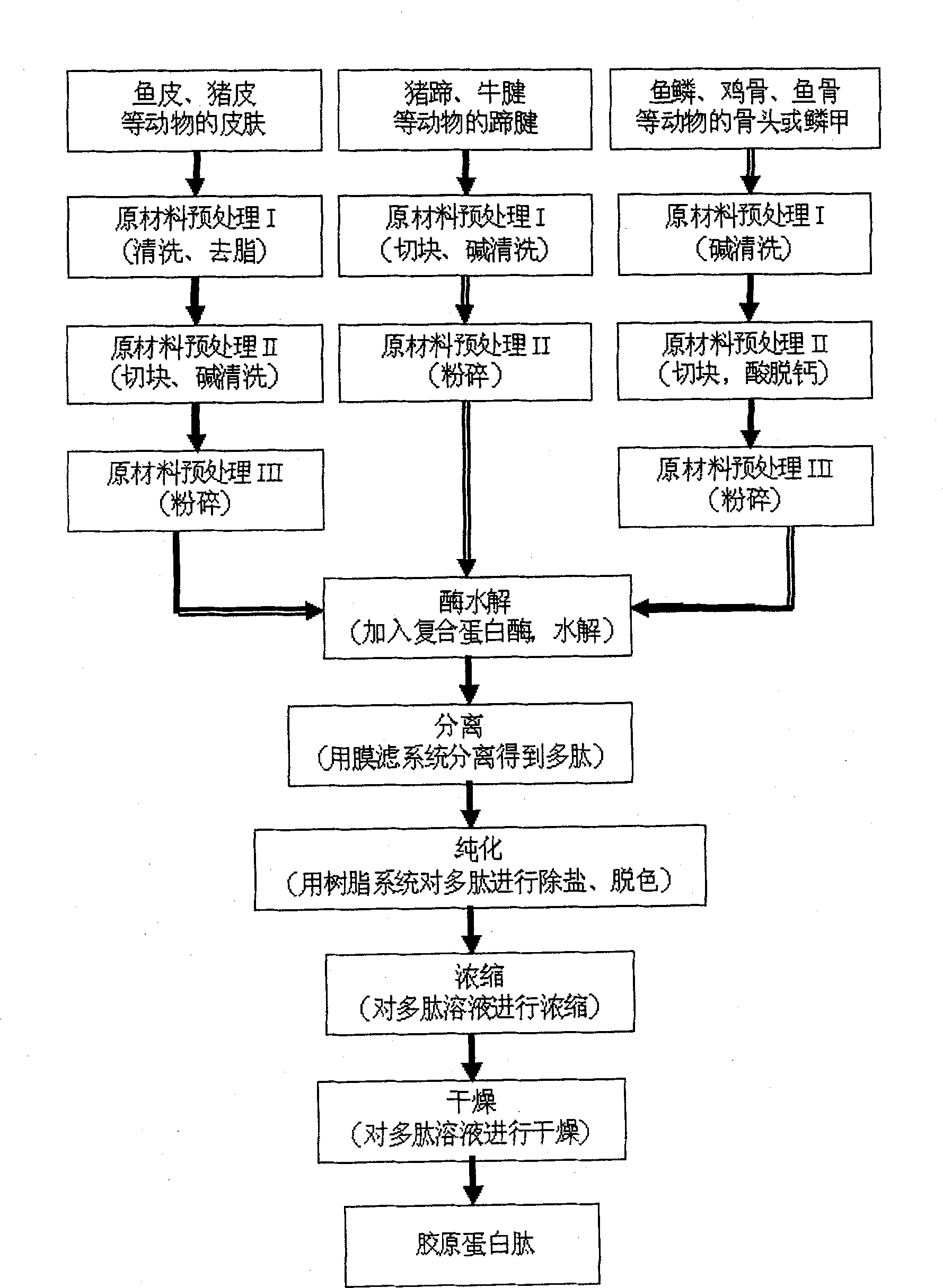

[0130] Preparation of Collagen Peptides

[0131] (1) Use animal skins such as pigskin and fish skin as raw materials

[0132] Using animal skins such as pigskin and fish skin as raw materials, the preparation of collagen polypeptides is carried out according to the following steps. The process flow is as follows: image 3 shown.

[0133] 1) Pretreatment of raw materials Ⅰ: Wash the fish skin or dehaired pig skin with tap water, remove the fat attached to the skin, and then add 1%-3% of Sodium chloride (m / v), heated to 40°C-50°C, and soaked under this condition for 30-45 minutes, poured off the liquid, and cleaned it again with tap water;

[0134] 2) Raw material pretreatment II: Cut the fish skin or dehaired pig skin treated in step 1) into small pieces with a cutting machine, and then add 1% according to the solid-liquid ratio of 1:1-1:3 (m / v) Sodium hydroxide (m / v), heated to 70°C-80°C, and soaked under this condition for 20-30 minutes, poured off the liquid, and cleaned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com