Ultraviolet-light curable aqueous heat-insulating nano composite coating and preparation method thereof

A nano-composite, ultraviolet light technology, applied in polyester coatings, polyether coatings, epoxy resin coatings, etc., can solve the problems of increased process and cost, visible light impermeability, human and environmental hazards, etc., to reduce the absorption rate , Fast curing speed, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

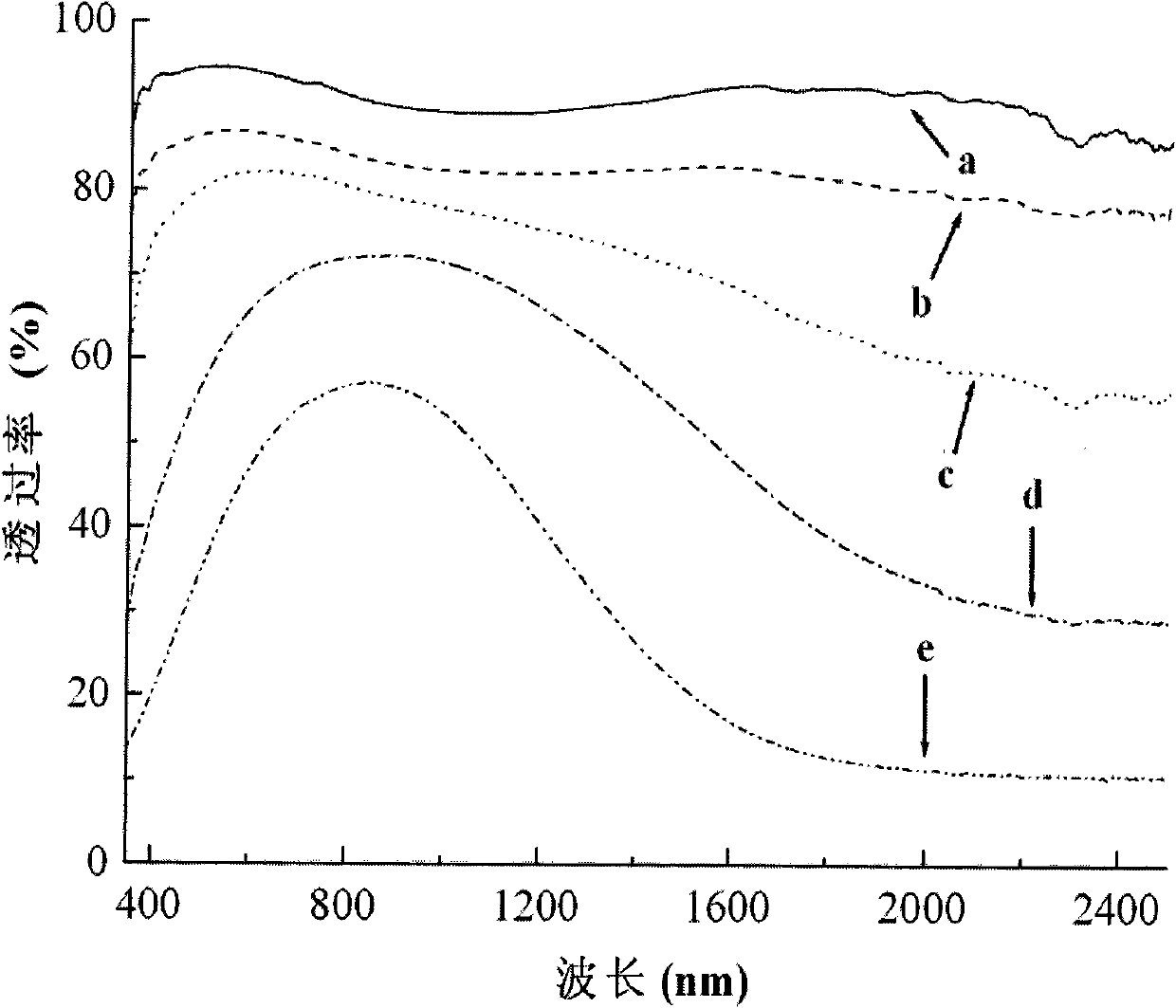

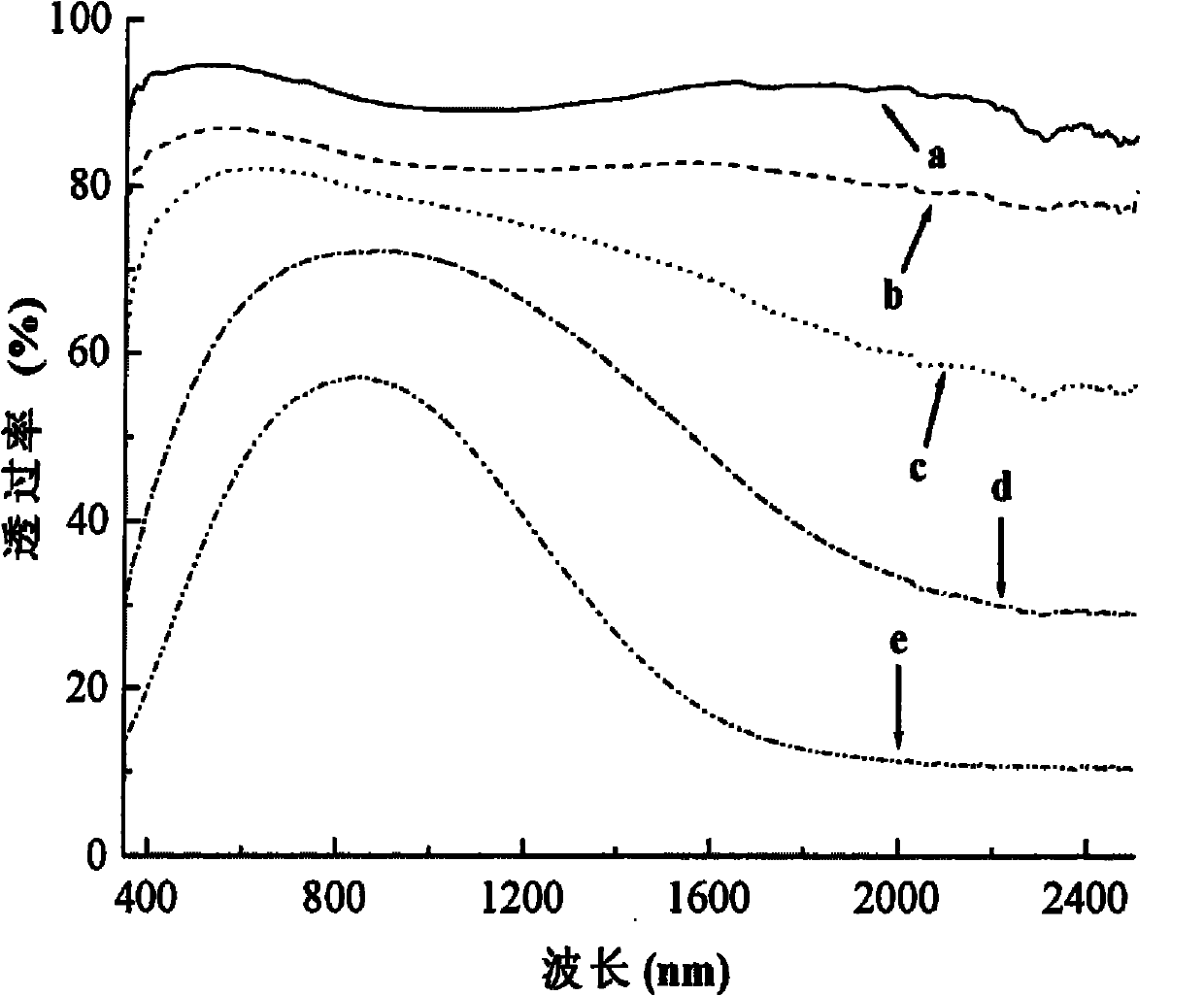

Embodiment 1

[0019] The formula of the nanometer tin oxide antimony composite coating by mass parts in the present embodiment is:

[0020] Polyurethane acrylate aqueous emulsion 85 parts

[0021] Nano tin antimony oxide paste 10 parts

[0022] Irgacure 2959 3.0 servings

[0023] Ammonia water 0.2 parts

[0024] Defoamer (BYK-088) 0.5 parts

[0025] Dispersant (SN-5040) 0.5 parts

[0026] Leveling agent (BYK-302) 0.8 parts

[0027] According to the above formula, 0.5 parts of modified polysiloxane defoamer (BYK-088), 0.5 parts of polyvalent carboxylate polymer dispersant (SN-5040), 0.8 parts of silicone resin type leveling agent (BYK-302), 3.0 parts of photoinitiator Irgacure 2959 are added to the aqueous emulsion of polyurethane acrylate, stirred at 500 rpm for 30 minutes with a high-speed mechanical emulsifier, and 0.2 parts of pH regulator ammonia water is added dropwise to the above emulsion to adjust its The pH value is the same as the pH value of the nano-antimony tin oxide slur...

Embodiment 2

[0030] The formula of the nanometer tin oxide antimony composite coating by mass parts in the present embodiment is:

[0031] Polyurethane acrylate aqueous emulsion 65 parts

[0032] Nano antimony tin oxide paste 20 parts

[0033] Irgacure 2959 3.0 servings

[0034] 2-Amino-2-methyl-1-propanol 1.0 parts

[0035] Defoamer (BYK-020) 0.2 parts

[0036] Dispersant (Deqian 912) 0.3 parts

[0037] Leveling agent (BYK-361) 0.5 parts

[0038] According to the formula, 0.2 parts of modified polysiloxane defoamer (BYK-020), 0.3 parts of polyacrylate amine salt dispersant (912), 0.5 parts of polyacrylate type leveling agent (BYK-361), Add 3.0 parts of photoinitiator Irgacure 2959 to polyurethane acrylate aqueous emulsion, disperse at a frequency of 40kHz for 15 minutes with an RS-120E ultrasonic cleaner, and add 0.2 parts of pH regulator 2-amino-2-methyl-1-propane Add alcohol dropwise to the above emulsion to adjust its pH to be the same as the pH of the nano-antimony tin oxide slu...

Embodiment 3

[0041] The formula of the nanometer tin oxide antimony composite coating by mass parts in the present embodiment is:

[0042] Epoxy acrylate aqueous emulsion 75 parts

[0043] Nano antimony tin oxide paste 25 parts

[0044]KIPEM 3.0 copies

[0045] Ammonia 0.6 parts

[0046] Defoamer (DCA-330) 0.3 parts

[0047] Dispersant (SN-5040) 0.3 parts

[0048] Leveling agent (BYK-306) 0.8 parts

[0049] According to the formula, 0.3 parts of polyacrylate defoamer (DCA-330), 0.3 parts of polyvalent carboxylate polymer dispersant (SN-5040), 0.8 parts of silicone resin type leveling agent (BYK-306 ), 3.0 parts of photoinitiator KIPEM were added to the epoxy acrylate water-based emulsion, and a high-speed mechanical emulsifier was used to stir at 1500rpm for 20 minutes, and 0.6 parts of ammonia water was added dropwise to the above-mentioned emulsion to adjust its pH value to that of the nano The pH value of the tin antimony oxide slurry is the same, then increase the speed to 2500rp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com