Method for preparing positive electrode material lithium iron phosphate of lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of long preparation cycle, complex process, and material grain growth, and achieve excellent electrochemical performance and production process The effect of simplicity and high purity of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

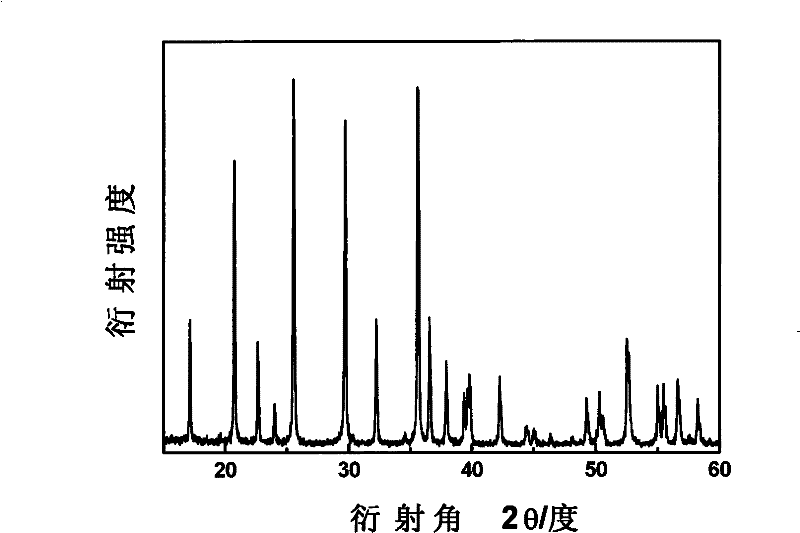

Image

Examples

Embodiment 1

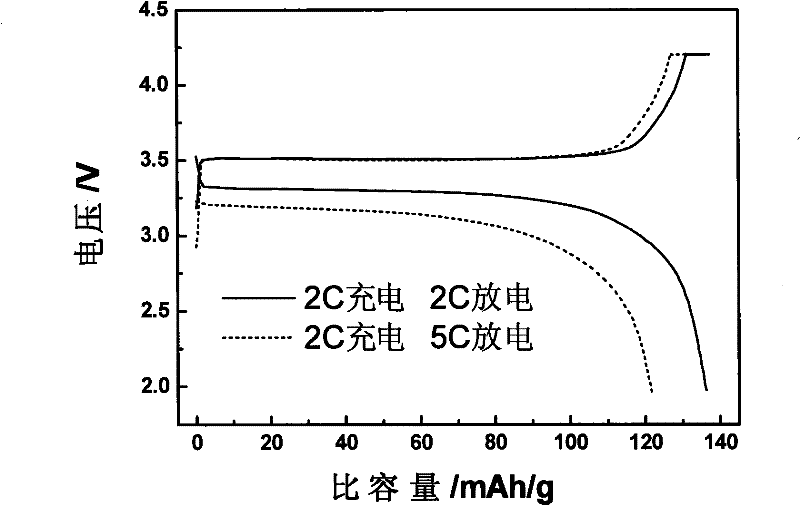

[0020] 10.7 g of ferric hydroxide, 10.6 g of lithium dihydrogen phosphate, and 10.0 g of 85% formic acid were mixed, placed in a planetary ball mill, and ball milled at a speed of 500 r / min for 30 min. After ball milling and mixing, heat at 80°C for 2 hours to react and dry, then add 2 grams of sucrose and put it in a ball mill again for 30 minutes, put the ball milled product in a high-temperature furnace, and heat it at 5°C / min in a nitrogen atmosphere Raise the temperature at a constant temperature of 600°C for 300 minutes, cool to room temperature, and obtain black LiFePO 4 / C powder.

[0021] The active material lithium iron phosphate powder, the conductive agent acetylene black and the binder polyvinylidene fluoride are mixed in a mass ratio of 85:5:10 and evenly coated on the aluminum foil to form a positive electrode sheet. In an argon atmosphere drying glove box, a lithium metal sheet was used as the counter electrode, Cellgard2300 membrane was used as the diaphragm,...

Embodiment 2

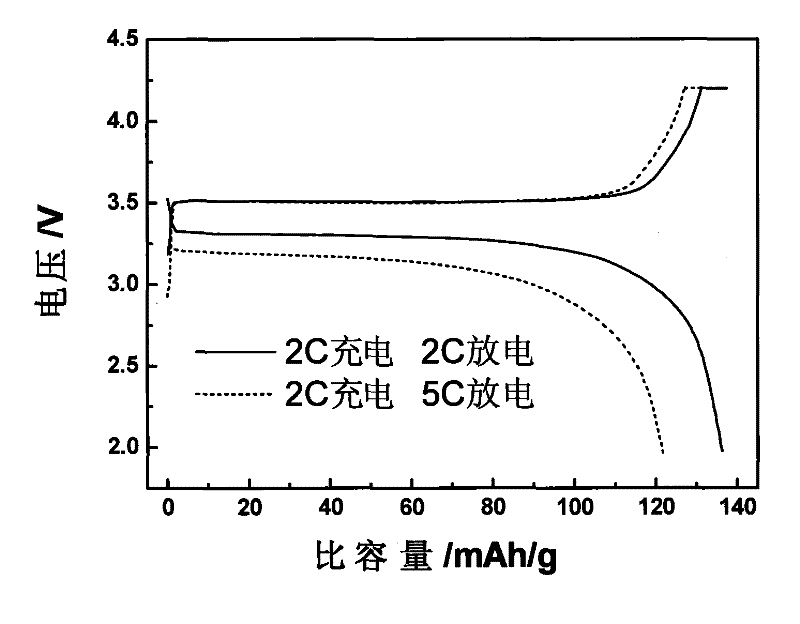

[0025] After mixing 19.3 grams of iron phosphate, 3.70 grams of lithium carbonate, 15 grams of deionized water and 2.5 grams of ascorbic acid in a ball mill for 90 minutes, they were reacted in a vacuum oven at 190°C for 2 hours. Example 1 method prepares LiFePO 4 / C powder.

[0026] The specific capacity of the obtained product is about 131mAh·g when discharged at 2C rate-1 .

Embodiment 3

[0028] Mix 8.0 grams of ferric oxide and 10.5 grams of lithium dihydrogen phosphate by ball milling. In a high-temperature reaction furnace, under a hydrogen atmosphere, heat up at a heating rate of 5°C / min, reduce at a constant temperature of 450°C for 200 minutes, cool to room temperature, and then mix with 1.0 gram of acetylene black ball milling and mixing, followed by the preparation of LiFePO by the method of Experimental Example 1 4 / C material.

[0029] The specific capacity of the obtained product is about 128mAh·g when discharged at 2C rate -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com