Treatment method of wastewater with high salt content and treatment device thereof

A treatment method and technology for wastewater treatment, which are applied in the fields of degassed water/sewage treatment, neutralized water/sewage treatment, and water/sewage multi-stage treatment. Reduced operating costs, improved system water recovery, and improved recovery effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Pilot test situation of treating high-salt wastewater on-site in a power plant:

[0078] 1. Pilot test water source: cooling tower circulating sewage.

[0079] 2. Pilot test water quality:

[0080]

[0081] 3. Drug specification for pilot test:

[0082] Name Purity

[0083] Slaked lime 85%

[0084] Polyiron (flocculant) 12% (calculated as Fe)

[0085] PAM industrial products

[0086] HCl 30%

[0087] NaClO 10%

[0088] NaCl industrial products

[0089] antiscalant concentrate

[0090] Reductant Industrial Products

[0091] NaOH 32%

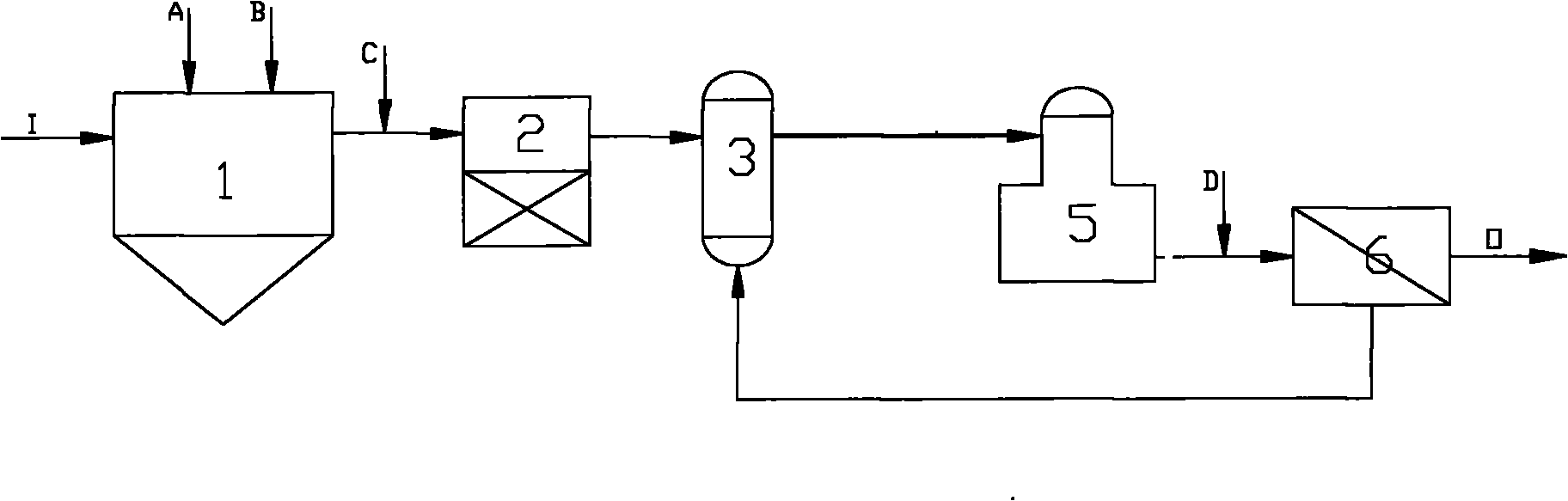

[0092] 4 Pilot test equipment process:

[0093]

[0094] 5 Test Equipment Specifications

[0095] The design output of the pilot test equipment is 1~2m3 / h, and the main equipment parameters are as follows:

[0097] Output: 2~3m3 / h

[0098] Dimensions: Ф3200×3750

[0099] Material: carbon steel

[0100] Motor power: 3kW

[0101] Ancillary equipment: lime dissolving dosing device, polyiron ...

Embodiment 2

[0176] Pilot test situation of treating high-salt wastewater on-site in a power plant:

[0177] 1. Pilot test water source: reverse osmosis concentrated water

[0178] 2. Pilot test water quality:

[0179] Reverse osmosis concentrated water quality

[0180]

[0181] 3. Drug specification for pilot test:

[0182] (same as embodiment 1)

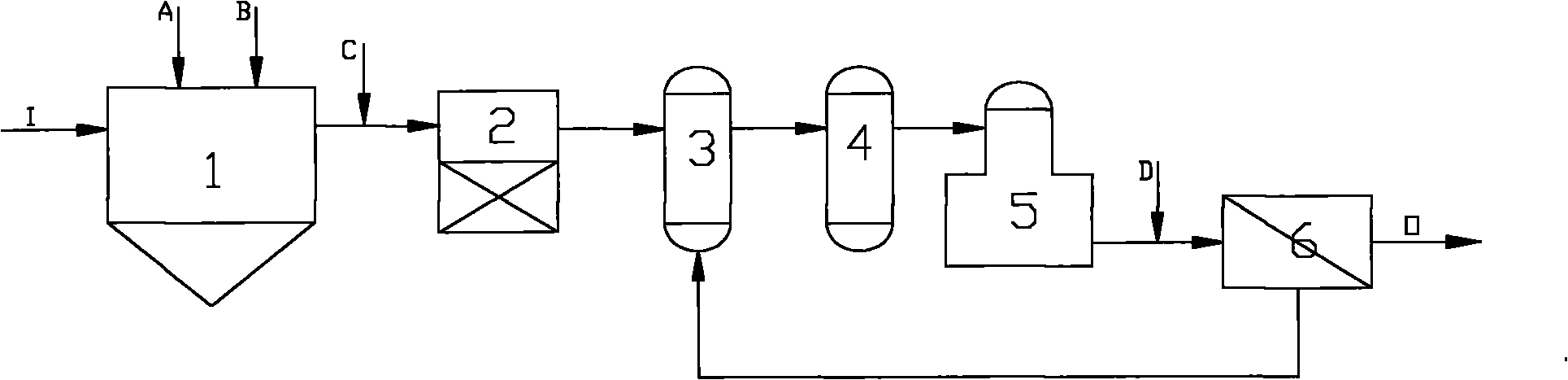

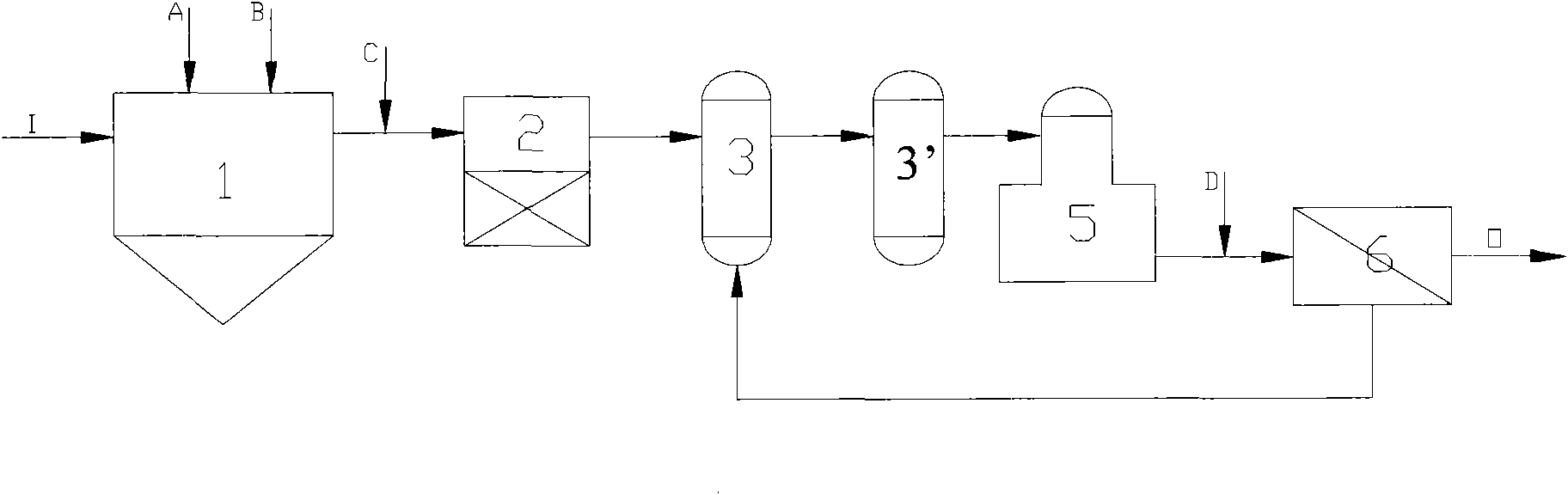

[0183] 4 Pilot test equipment process:

[0184] For reverse osmosis concentrated water, the following process is adopted:

[0185]

[0186] 5 Test equipment specifications:

[0187] The design output of the pilot test equipment is 1~2m3 / h, and the main equipment parameters are as follows:

[0189] Output: 2~3m3 / h

[0190] Dimensions: Ф3200×3750

[0191] Material: carbon steel

[0192] Motor power: 3kW

[0193] Ancillary equipment: lime dissolving dosing device, polyiron dosing device, PAM dosing device, hydrochloric acid dosing device

[0194] 5.2. Quartz sand filter

[0195] Output: 2~3m3 / h

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com