Method for preparing carbon/carbon composite material nanometer silicon carbide-mullite composite external coating

A carbon composite material and nano-silicon carbide technology, which is applied in the field of preparing carbon/carbon composite material composite outer coating, can solve the problems of easy cracking coating thickness, instant noodles cracking, shortage, etc., and achieves improved high-temperature oxidation resistance, high heat Effects of stability and antioxidant properties, good physicochemical compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

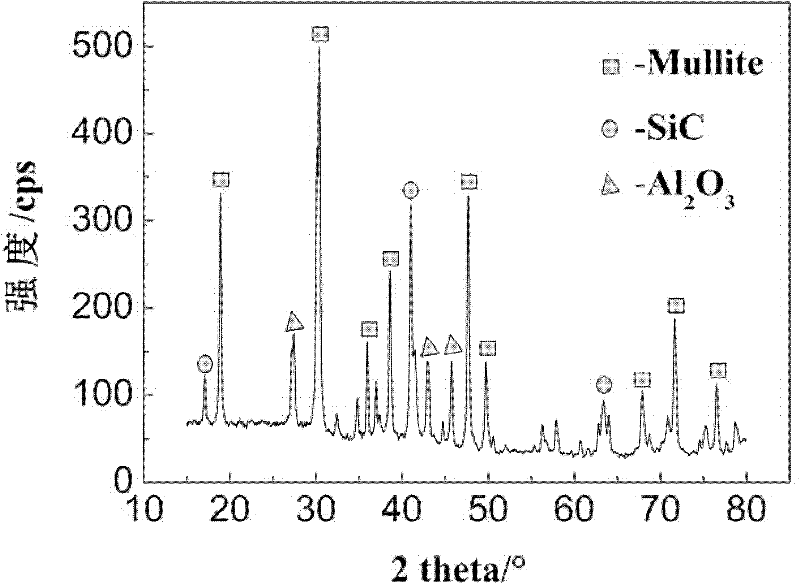

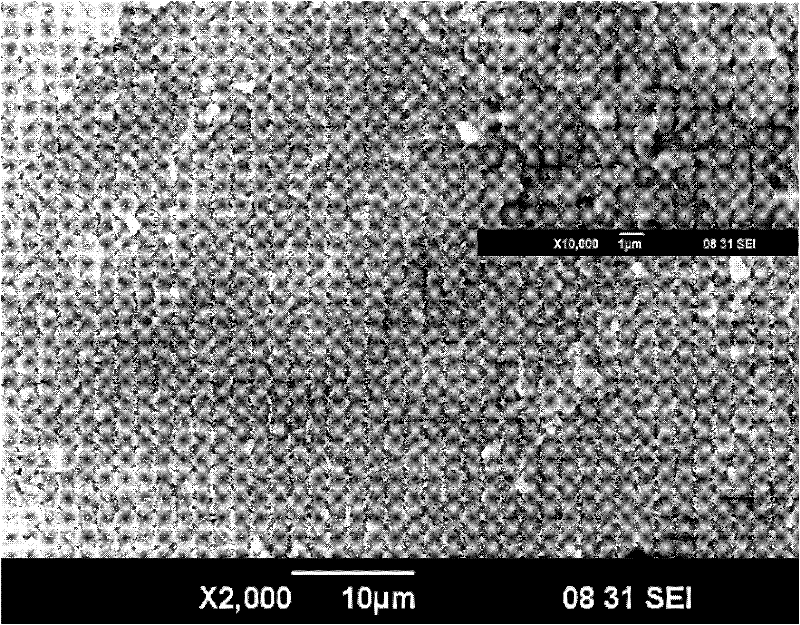

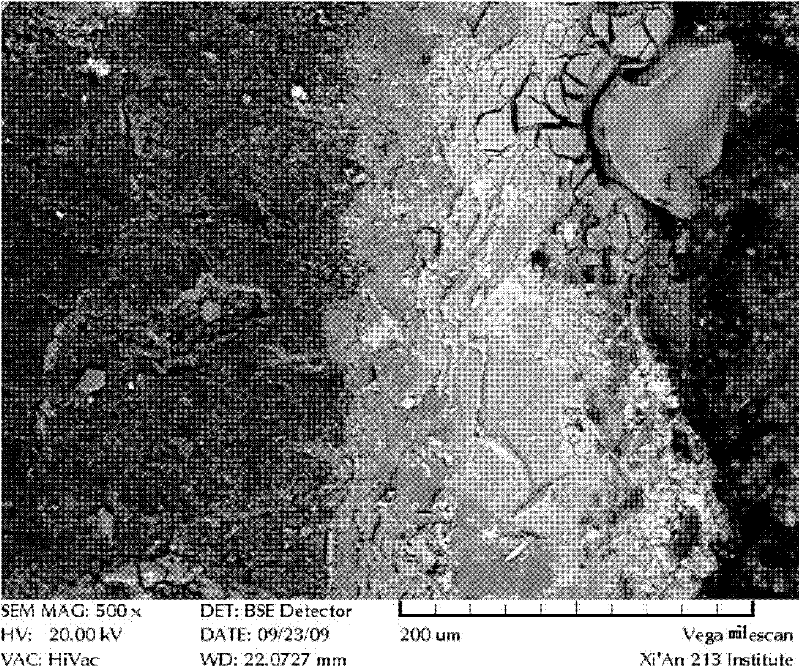

[0012] Example 1: 1) Preparation of acicular mullite powder First, 4ml of SiO 2 %≥28% tetraethyl orthosilicate was dissolved in 20ml of absolute ethanol, then 10ml of distilled water was added, the pH of the solution was adjusted to 2 with hydrochloric acid, and magnetically stirred for 0.5h at room temperature to fully prehydrolyze the tetraethyl orthosilicate, calculated as Solution A; Secondly, take 24g of Al(NO 3 ) 3 9H 2 Add O into 10ml of distilled water and stir until Al(NO 3 ) 3 9H 2After O is fully dissolved, pour it into solution A, place the mixed solution on a magnetic stirrer and stir evenly, then adjust the pH value to 4.5 with ammonia water, and calculate it as solution B; then, dry solution B at 60°C to dry Then put the dry gel into the microwave hydrothermal reaction kettle, add distilled water to the 2 / 3 of the volume of the reaction kettle, and control the temperature at 160°C in the microwave reactor. Finally, the dried samples were calcined in a muff...

Embodiment 2

[0013] Example 2: 1) Preparation of acicular mullite powder First, 5ml of SiO 2 %≥28% ethyl orthosilicate was dissolved in 20ml of absolute ethanol, then 15ml of distilled water was added, the pH value of the solution was adjusted to 3 with hydrochloric acid, magnetically stirred at room temperature for 1.5h to fully pre-hydrolyze the orthosilicate, calculated as Solution A; Secondly, take 25.5g of Al(NO 3 ) 3 9H 2 O was added to 15ml of distilled water and stirred at room temperature until Al(NO 3 ) 3 9H 2 After O is fully dissolved, pour it into solution A, place the mixed solution on a magnetic stirrer and stir evenly, then adjust the pH value to 5 with ammonia water, and calculate it as solution B; then, dry solution B at 60°C to dry Then put the dry gel into the microwave hydrothermal reaction kettle, add distilled water to the 2 / 3 of the volume of the reaction kettle, and control the temperature at 180°C in the microwave reactor. Finally, the dried samples were cal...

Embodiment 3

[0014] Embodiment 3: 1) Preparation of acicular mullite powder At first, the SiO of 6ml 2 %≥28% ethyl orthosilicate is dissolved in 20ml of absolute ethanol, then add 20ml of distilled water, adjust the pH value of the solution to 4 with hydrochloric acid, stir magnetically for 3 hours at room temperature to fully pre-hydrolyze the orthosilicate, and count it as a solution A; Secondly, take 27g of Al(NO 3 ) 3 9H 2 O was added to 20ml of distilled water, and stirred at room temperature until Al(NO 3 ) 3 9H 2 After O is fully dissolved, pour it into solution A, place the mixed solution on a magnetic stirrer and stir evenly, then adjust the pH value to 5.5 with ammonia water, and calculate it as solution B; then, dry solution B at 60°C to dry Then put the dry gel into the microwave hydrothermal reaction kettle, add distilled water to the 2 / 3 of the volume of the reaction kettle, and control the temperature at 200°C in the microwave reactor. Finally, the dried samples were c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com