Long-service-life high-speed acid environment protection bright chemical nickel plating additive and use method thereof

A technology of electroless nickel plating and additives, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problem of low stability and achieve stable coating performance and speed, bright coating, and stable plating solution good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Preparation of Thiourea Derivatives

[0053] a. Add 200g of PEG600 to three four-neck bottles, add 500ml of acetone to each, then add 15g of thiourea, N 2 Under protection, slowly reflux for 5 hours, then cool to room temperature; wash the organic phase with saturated brine; remove the solvent under reduced pressure to obtain a solid, and obtain a white solid.

[0054] b. Add 200g of PEG100 into three four-neck bottles, add 500ml of acetone each, and then add 15g of thiourea, N 2 Under protection, slowly reflux for 5 hours, then cool to room temperature; wash the organic phase with saturated brine; remove the solvent under reduced pressure to obtain a solid, and obtain a white solid.

[0055] c. Add 200g of PEG2000 to three four-necked bottles, add 500ml of acetone to each, and then add 15g of thiourea, N 2 Under protection, slowly reflux for 5 hours, then cool to room temperature; wash the organic phase with saturated brine; remove the solvent under reduced pressure ...

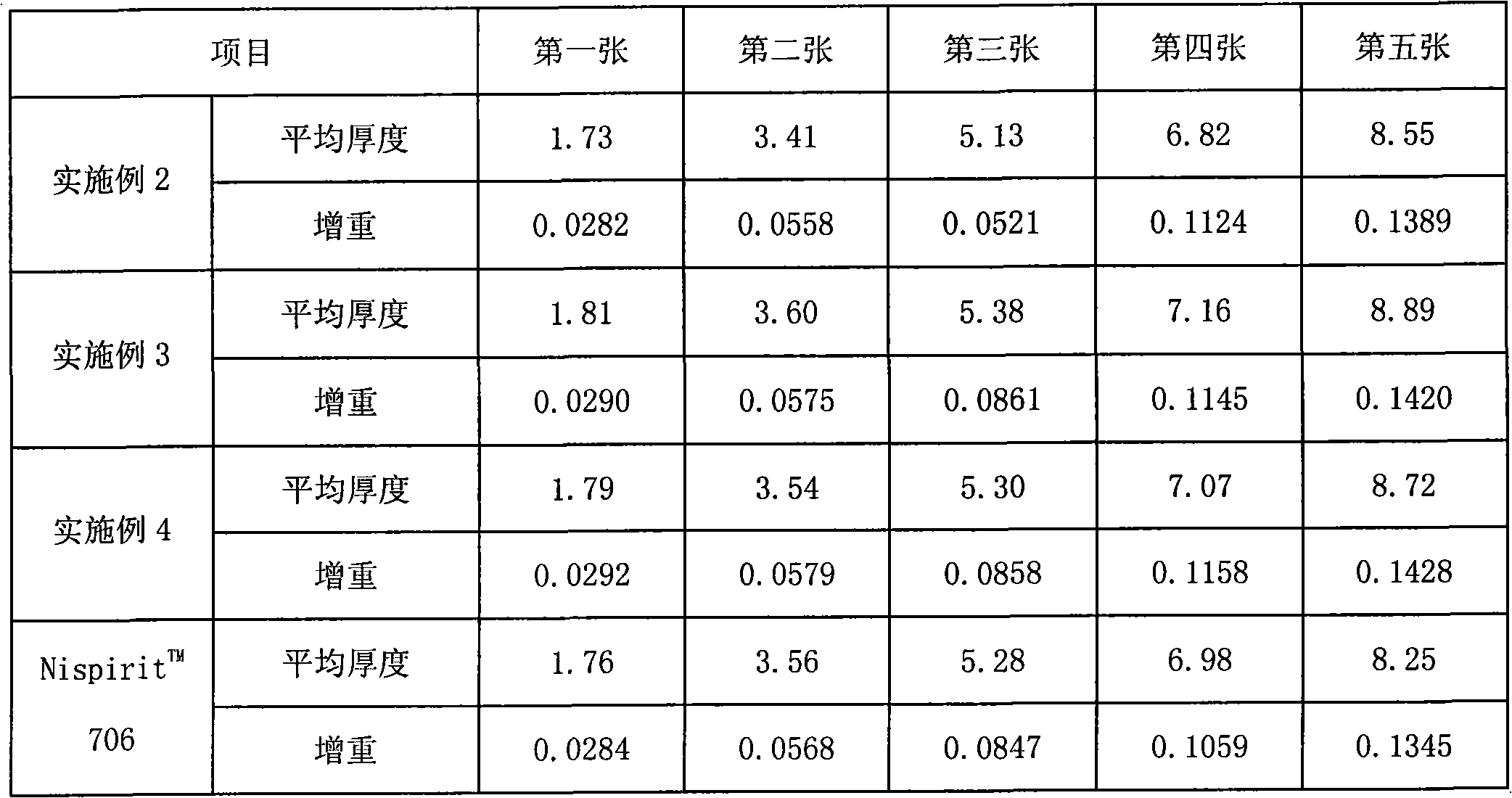

Embodiment 2

[0057] The stabilizer in this example is selected from the thiourea derivative prepared in Example 1 (a) and potassium iodate in a weight ratio of 1:20 to form a composite stabilizer.

[0058] (1) Agent A (1L as an example):

[0059] NiSO 2 ·6H 2 O 430g

[0060] Lactic acid 45g

[0061] Composite stabilizer 0.4g,

[0062] Preparation:

[0063] a. Add about 1 / 2 of the required amount of water and heat to about 70°C;

[0064] b. Add nickel sulfate and stir until completely dissolved;

[0065] c. Add 6g of activated carbon, stir evenly and let it stand for 2 hours, filter out the activated carbon;

[0066] d. Add buffer and complexing agent, stir until completely dissolved;

[0067] e. Dissolve the stabilizer with hot water, then pour it into the solution prepared in step d, add water to the required scale, stir evenly, and obtain Agent A for later use.

[0068] (2) Agent B (1L as an example):

[0069] Sodium hypophosphite 180g

[0070] Lactic acid 100g

[0071] Malic...

Embodiment 3

[0098] The stabilizer in this embodiment is selected from the thiourea derivative prepared in Example 1 (b) and potassium bromate in a weight ratio of 1:15 to form a composite stabilizer.

[0099] (1) Agent A (1L as an example):

[0100] NiSO 2 ·6H 2 O 435g

[0101] Sodium acetate 20g

[0102] Sodium tetraborate 15g

[0103] Composite stabilizer 0.5g,

[0104] a. Add about 1 / 2 of the required amount of water and heat to about 70°C;

[0105] b. Add nickel sulfate and stir until completely dissolved;

[0106] c. Add 8g of activated carbon, stir evenly and let it stand for 1 hour, then filter out the activated carbon;

[0107] d. Add buffer and complexing agent, stir until completely dissolved;

[0108] e. Dissolve the stabilizer with hot water, then pour it into the solution prepared in step d, add water to the required scale, stir evenly, and obtain Agent A for later use.

[0109] Agent B (1L as an example):

[0110] Sodium hypophosphite 190g

[0111] Lactic acid 115...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com