Coal chemical industry wastewater zero emission treatment method and system

A technology for coal chemical wastewater and treatment methods, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, adsorbed water/sewage treatment, etc., can solve the problem of COD value difficult to reach the standard, polycyclic aromatic hydrocarbons and heterocyclic aromatic hydrocarbons. The degradation ability is limited , increase the cost of water treatment and other issues to achieve the effect of saving water resources and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

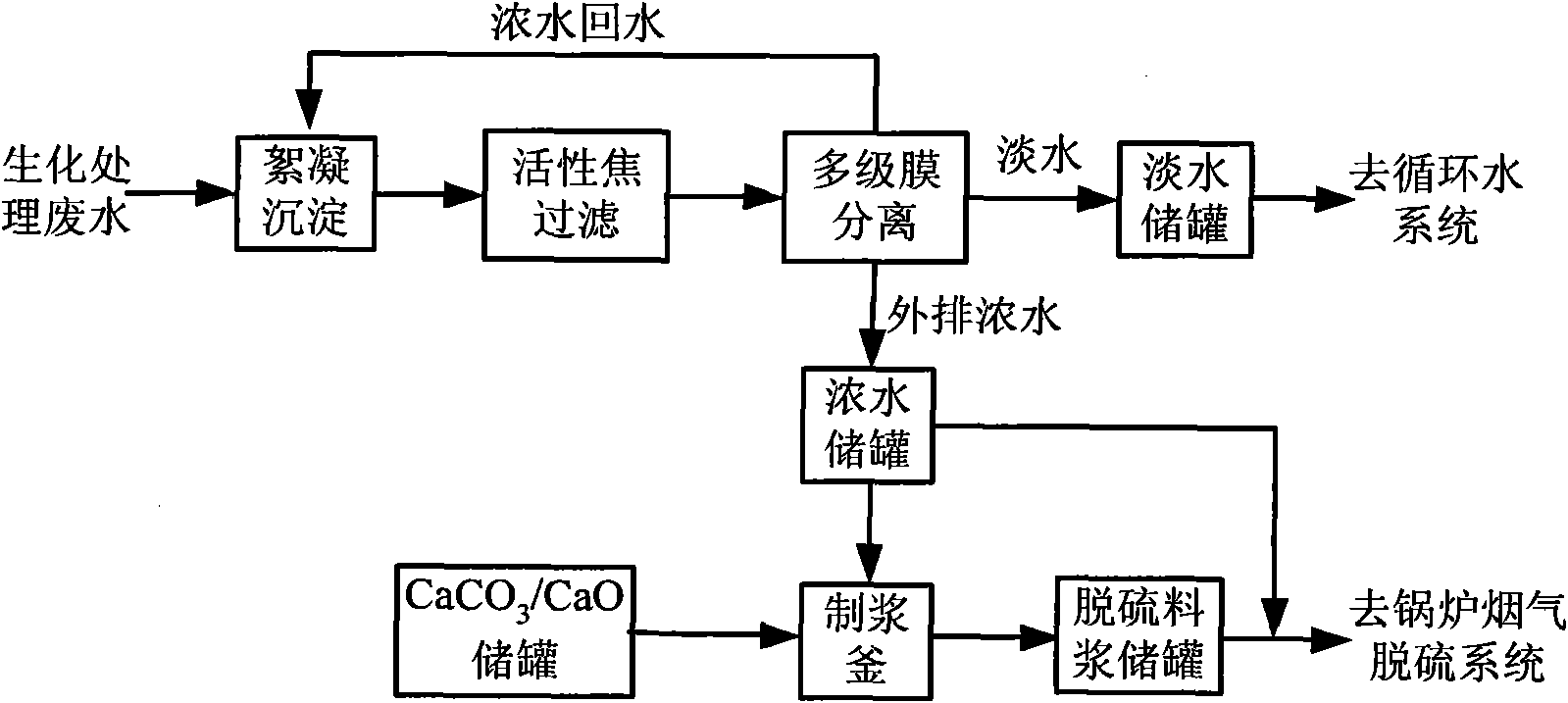

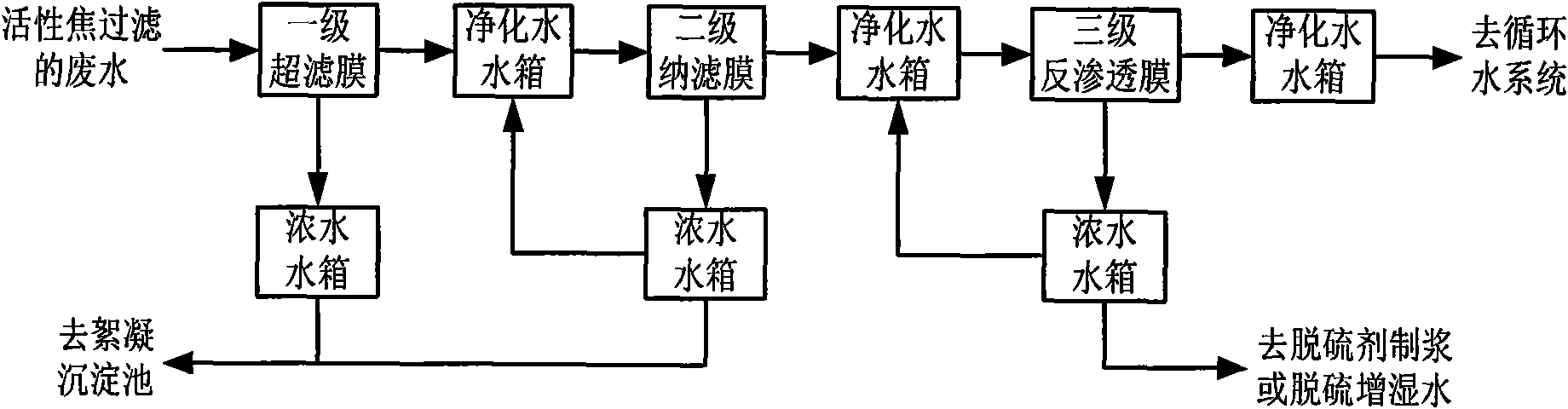

[0038] The water treatment equipment consists of a flocculation sedimentation tank, an active coke filter bed, a multi-stage membrane separation system and a pulping tank. The length, width and height of the flocculation sedimentation tank are 1.5m, 0.5m and 1m respectively. The length, width and thickness of the active coke filter bed are 1m, 0.5m and 0.5m respectively. The active coke is activated coke made of bituminous coal, with a particle size of 1-10mm, a bulk specific gravity of 0.81g / ml, and a specific surface area of 370m2 / g. The multi-stage membrane separation system consists of a first-stage ultrafiltration membrane, a second-stage nanofiltration membrane and a third-stage reverse osmosis membrane. The first-stage membrane can intercept substances with a molecular weight above 60,000, and is used for primary purification of water. The model is AQU90; the second-stage membrane For organic matter and ions with a molecular weight cut-off of 300 or more, model NE404...

specific Embodiment 2

[0042] Water treatment equipment is as described in specific embodiment one;

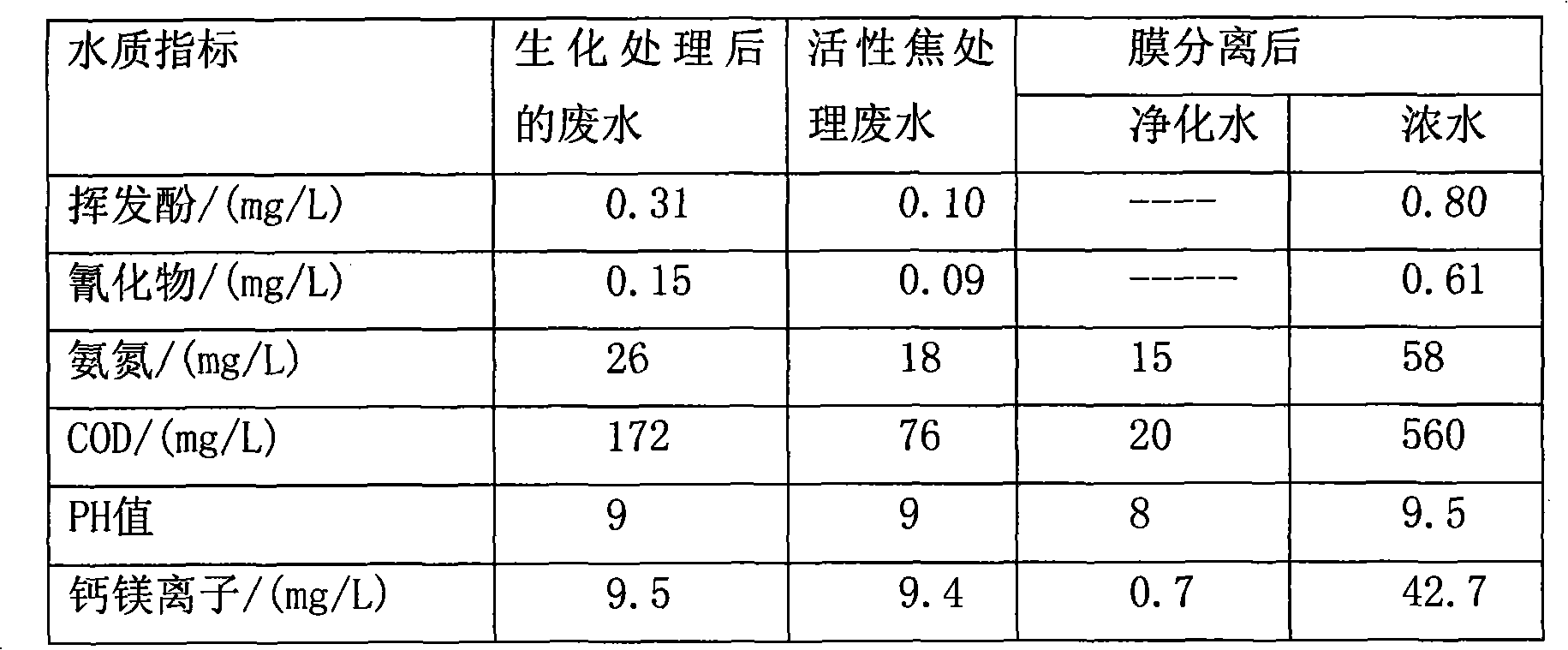

[0043] After biochemical treatment, the wastewater produced by the Lurgi gasification process enters the flocculation sedimentation tank, and polymer flocculants are added to the flocculation sedimentation, and after flocculation sedimentation, it enters the activated coke adsorption filter bed, and the filtration rate of the wastewater is controlled to 0.2m3 / h to remove the suspension in the water matter, macromolecular organic matter and some ammonia nitrogen. Then, it is sent into the multi-stage membrane separation system by the water pump. The purified water recovery rate of the primary ultrafiltration membrane is 90%, and all the separated concentrated water returns to the flocculation and sedimentation system, and the purified water enters the secondary nanofiltration membrane; the purified water recovery rate of the secondary membrane is 90%, and 80% of the separated concentrated water is retu...

specific Embodiment 3

[0046] Water treatment equipment is as described in specific embodiment one;

[0047] After biochemical treatment, the coking wastewater enters the flocculation sedimentation tank. Polymer flocculants are added to the flocculation sedimentation. After flocculation sedimentation, it enters the activated coke adsorption filter bed. The filtration rate of wastewater is controlled to 0.2m3 / h to remove suspended solids, macromolecular organic matter and Part of ammonia nitrogen. Then, it is sent into the multi-stage membrane separation system by the water pump. The purified water recovery rate of the primary ultrafiltration membrane is 90%, and all the separated concentrated water returns to the flocculation and sedimentation system, and the purified water enters the secondary nanofiltration membrane; the purified water recovery rate of the secondary membrane is 90%, and 80% of the separated concentrated water is returned to the flocculation system In the sedimentation system, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com