Transition metal phosphate-clad composite lithium ion battery anode material

A composite positive electrode material and lithium-ion battery technology, applied in the direction of non-aqueous electrolyte battery electrodes, etc., can solve the problems of no electrochemical activity, poor rate performance, unsafe and other problems, achieve good cycle performance and rate performance, and improve cycle performance And magnification performance, the effect of simple and easy to control the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

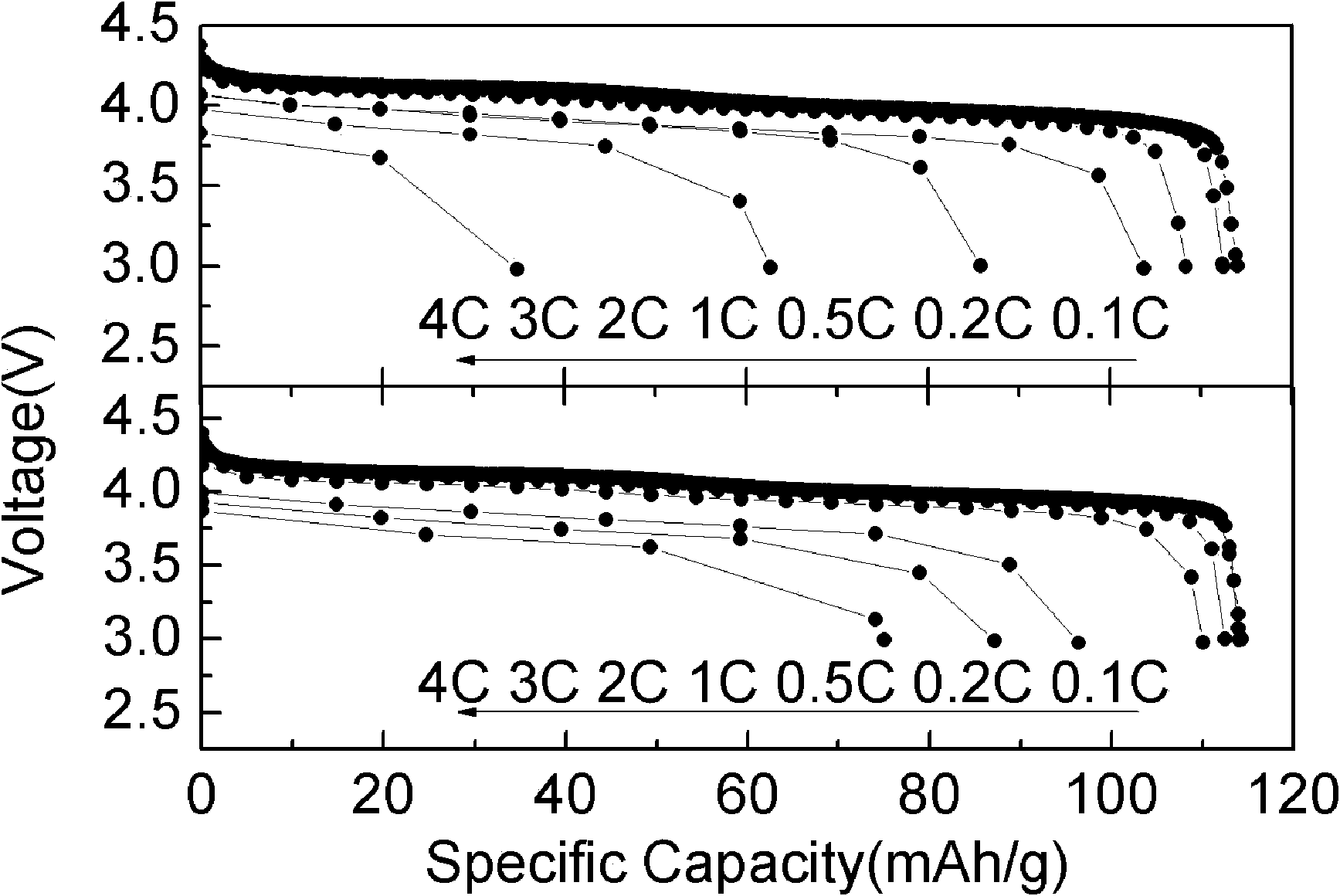

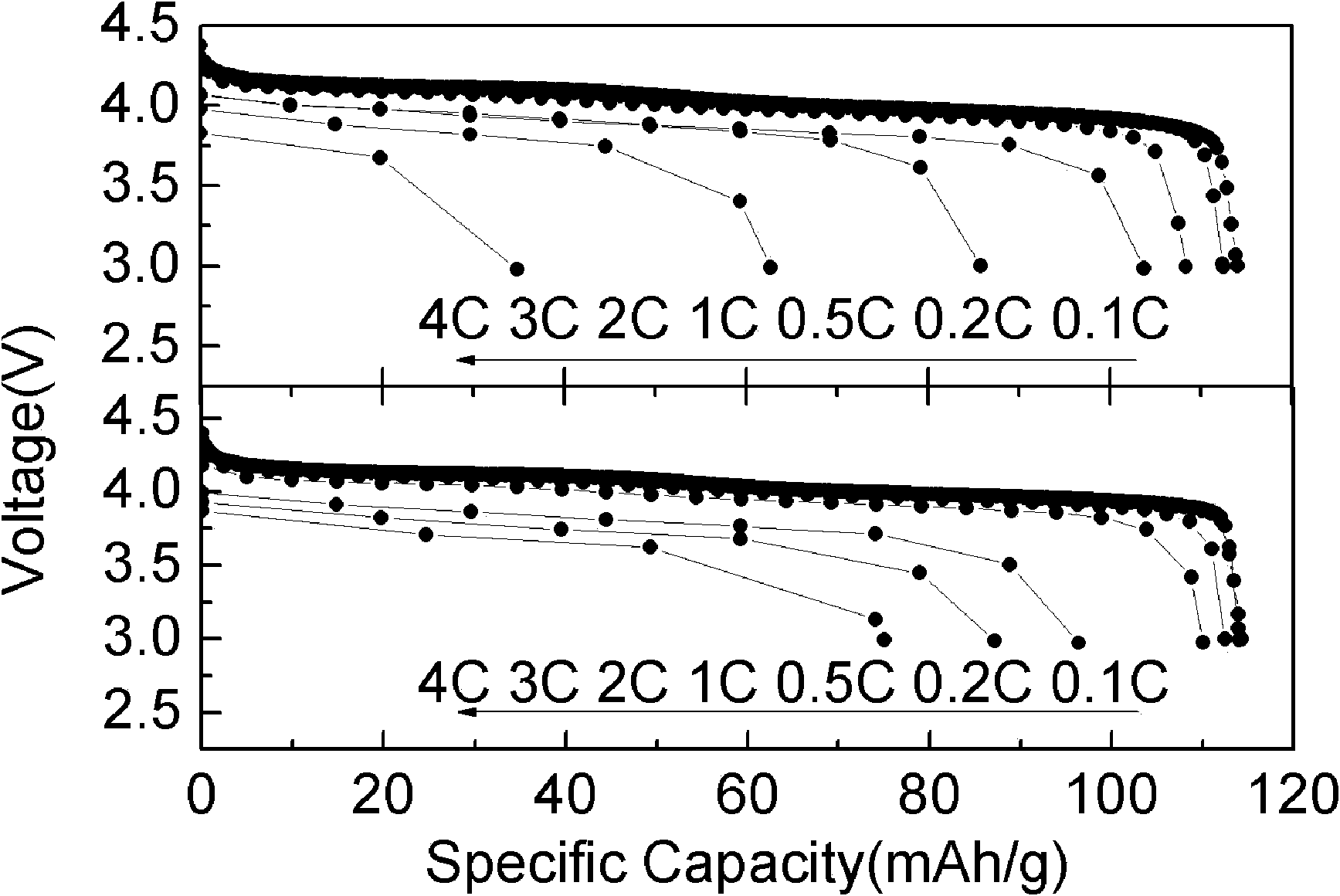

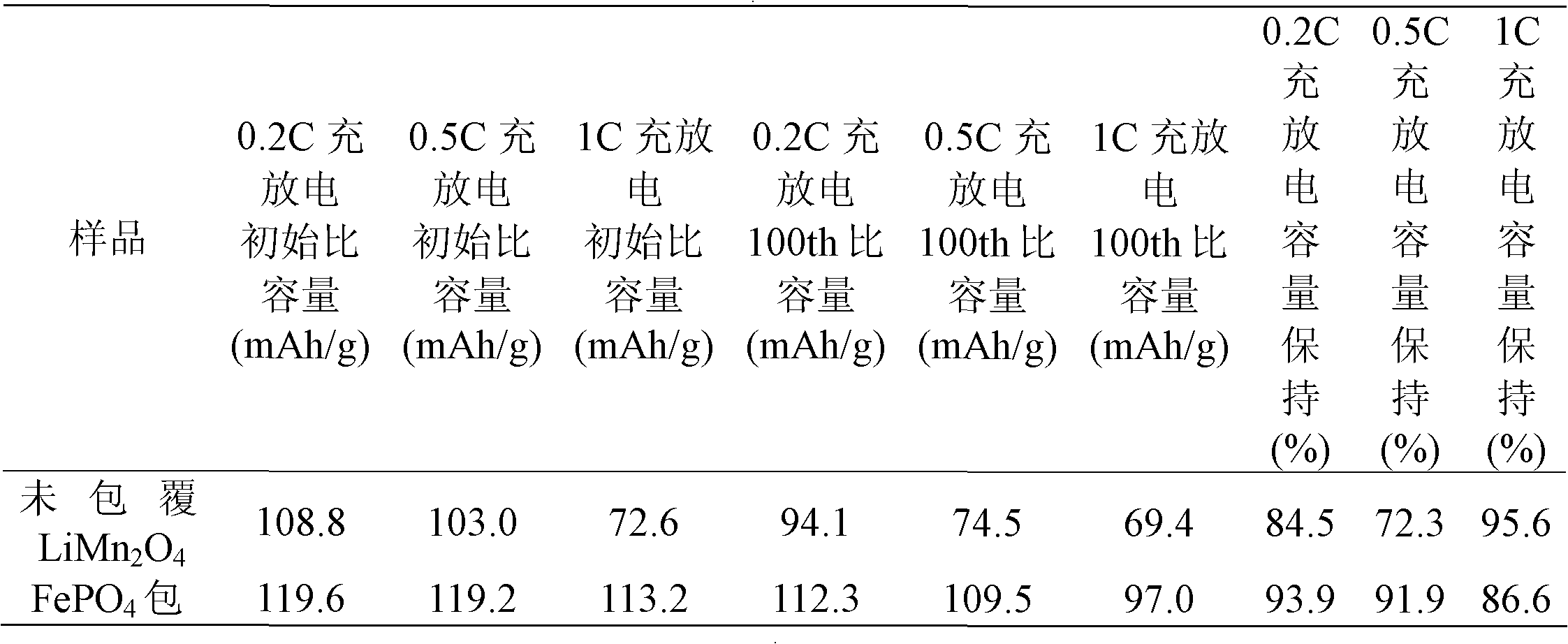

[0011] Embodiment 1 core is lithium manganese oxide LiMn 2 o 4 , the shell is iron phosphate FePO 4 Composite electrode material

[0012] Lithium manganese oxide LiMn prepared by solid-state sintering 2 o 4 Fine powder dispersed in ferrous sulfate FeSO 4 In the aqueous solution, after stirring for a period of time, the Fe 2+ with PO 4 3- Ammonium dihydrogen phosphate NH with a molar ratio of 1:1 4 h 2 PO 4 The aqueous solution was slowly added to the above suspension, and after mechanical stirring for a period of time, the obtained product was separated by filtration, dried at 130°C, and then sintered at 550°C. The outer shell iron phosphate FePO in the resulting composite electrode material 4 Lithium manganese oxide LiMn 2 o 4 1% of the mass ratio. Using a lithium sheet as the negative electrode, the uncoated lithium manganate LiMn at room temperature was measured 2 o 4 and iron phosphate FePO 4 Coated lithium manganese oxide LiMn 2 o 4 The magnification pe...

Embodiment 2

[0016] Example 2 The core is lithium manganate LiAl doped with aluminum 0.02 mn 1.98 o 4 , the shell is titanium phosphate TiPO 4 composite electrode materials.

[0017] Al-doped lithium manganate LiAl prepared by sol-gel method 0.02 mn 1.98 o 4 fine powder dispersed in titanium nitrate Ti(NO 3 ) 3 In the aqueous solution, after ultrasonic stirring for a period of time, the Ti 3+ with PO 4 3- Ammonium dihydrogen phosphate NH with a molar ratio of 1:1 4 h 2 PO 4 The aqueous solution is slowly added to the above suspension, and after reacting and aging for a period of time, the obtained product is separated by filtration, dried at 80°C, and then sintered at 300°C. Titanium phosphate TiPO in the obtained composite electrode material 4 LiAl 0.02 mn 1.98 o 4 0.01% of the mass ratio.

Embodiment 3

[0018] Embodiment 3 core is lithium nickelate LiNiO 2 , the shell is vanadium phosphate VPO 4 Composite electrode material

[0019] Lithium nickelate LiNiO prepared by hydrothermal / solvothermal method 2 Fine powder dispersed in vanadium chloride VCl 3 In the aqueous solution, after a period of magnetic stirring, the V 3+ with PO 4 3- Ammonium dihydrogen phosphate NH with a molar ratio of 1:1 4 h 2 PO 4 The aqueous solution is slowly added to the above suspension, and after reacting and aging for a period of time, the obtained product is separated by filtration, dried at 90°C, and then sintered at 350°C. The shell vanadium phosphate VPO in the resulting composite electrode material 4 Occupying core lithium nickelate LiNiO 2 0.1% of the mass ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com