Multichannel carbon nanotube sensor and preparation method thereof

A carbon nanotube and carbon nanotube composite technology, which is applied in the field of microelectronics, can solve the problems of poor IC integrated circuit compatibility, poor reliability, weak current, etc., and achieve improved reliability and stability, stable and reliable combination, and high detection sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

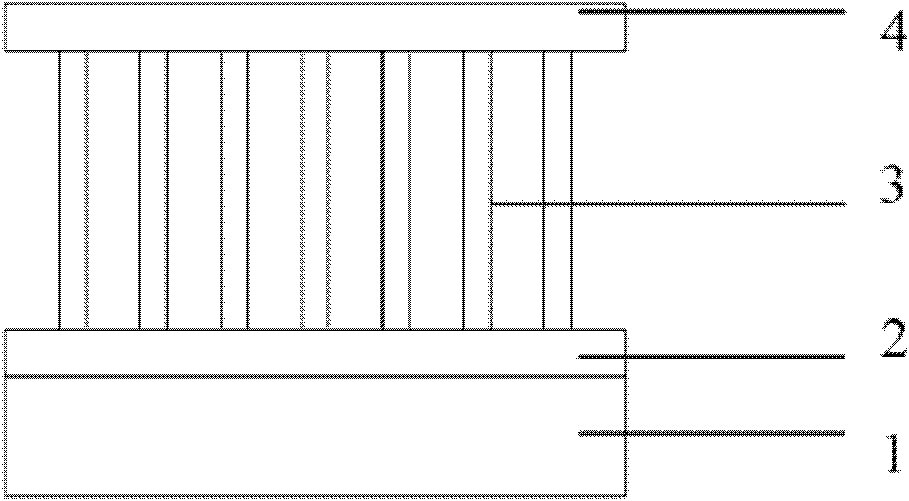

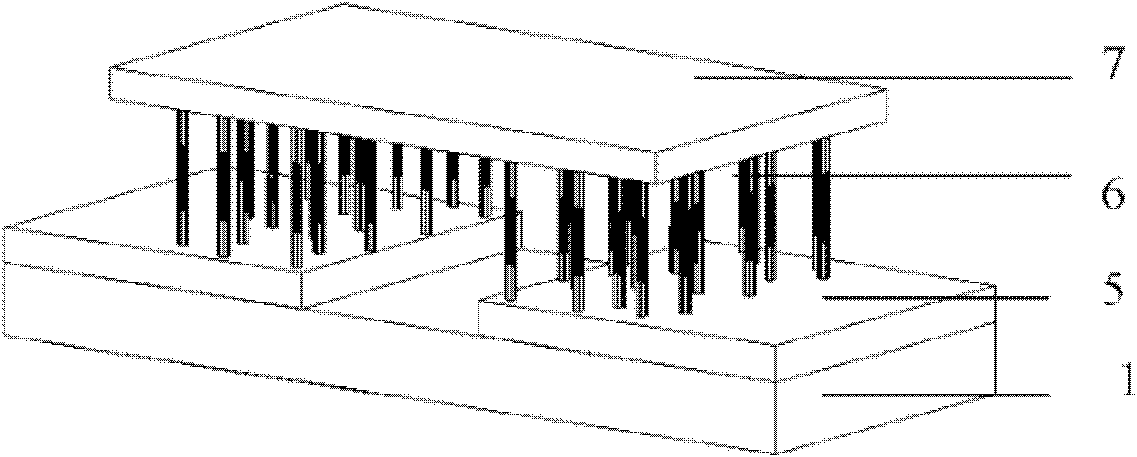

[0045] 1. Utilize the common PECVD method (plasma-enhanced chemical vapor deposition method) for preparing carbon nanotube field emission cathode arrays to obtain uniformly oriented multi-walled carbon nanotube arrays on silicon wafers deposited with nickel metal catalysts, using conventional photolithography The patterning process enables the nickel catalyst to be patterned on the silicon wafer, thereby realizing the patterning treatment of the conductive channel of the carbon nanotube, and the length of the carbon nanotube is 10 μm;

[0046] 2. Spin-coat the photoresist on the substrate to cover the carbon nanotube array. The thickness of the photoresist is 15 μm, bake the glue, and grind the photoresist with sandpaper so that the thickness of the photoresist is about 8 μm

[0047] 3. Use a sodium hydroxide solution with a concentration of 0.5% to control the etching of the photoresist for 30 seconds; 4. Deposit a Cr / Cu seed layer on the surface of the above structure, wherei...

Embodiment 2

[0056] 1. Utilize the common PECVD method (plasma-enhanced chemical vapor deposition method) for preparing carbon nanotube field emission cathode arrays to obtain uniformly oriented multi-walled carbon nanotube arrays on silicon wafers deposited with iron metal catalysts. The length is 10 μm;

[0057] 2. Spin-coat the photoresist on the substrate to cover the carbon nanotube array. The thickness of the photoresist is 15 μm, bake the glue, and grind the photoresist with sandpaper so that the thickness of the photoresist is about 8 μm

[0058] 3. Conduct photolithographic patterning on the conductive channel of carbon nanotubes. After removing the glue, perform RIE etching to remove the exposed carbon nanotubes, and fill them with spin-coated photoresist;

[0059] 4. Use a sodium hydroxide solution with a concentration of 0.6% to perform controlled etching on the photoresist for 25 seconds;

[0060] 5. Deposit a Cr / Cu seed layer on the surface of the above structure, wherein th...

Embodiment 3

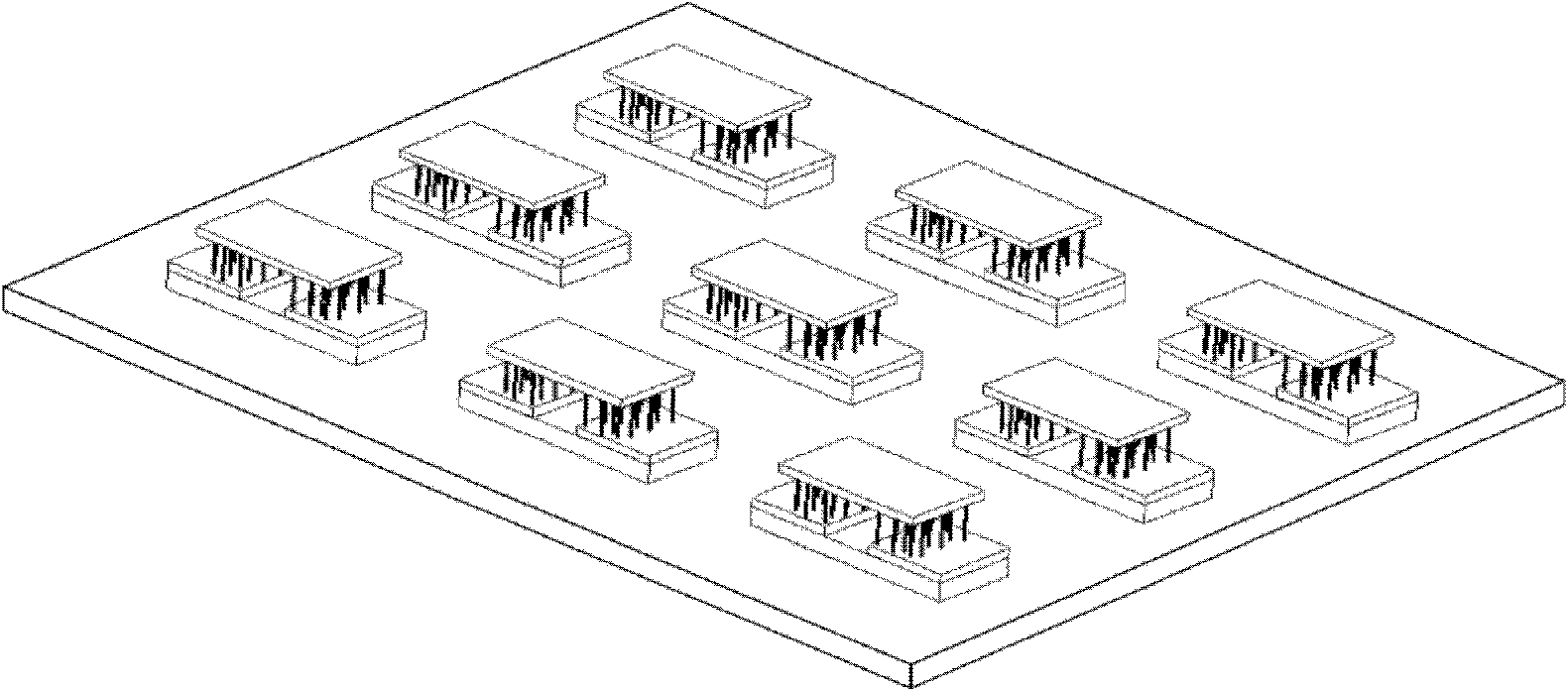

[0069] The carbon nanotube sensor preparation process based on the carbon nanotube finished product is as follows:

[0070] 1. Purify the multi-walled carbon nanotubes with a length of 10 μm obtained by the usual preparation method, mix them with photoresist in proportion, the mass ratio of carbon nanotubes and photoresist is 1:8, and mix them with a ball mill for 5 Hour;

[0071] 2. Spin-coat 8 μm photoresist on the silicon wafer and pattern it, then spin-coat the mixture of photoresist and carbon nanotubes, fill and cover the patterned photoresist pattern, dry it, and grind it with sandpaper until Expose the first layer of photoresist;

[0072] 3. Use a sodium hydroxide solution with a concentration of 0.4% to perform controlled etching on the photoresist for 40 seconds;

[0073] 4. Deposit a Cr / Cu seed layer on the surface of the above structure, wherein the thickness of Cr Cu thickness is

[0074] 5. Spin-coat photoresist on the above-mentioned Cr / Cu seed layer and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com