Submicron copper powder and method for preparing same by sulfuric acid-process chemical reduction

A technology of submicron copper powder and sulfate, which is applied in the field of submicron copper powder and the preparation of the copper powder by sulfuric acid chemical reduction, can solve the problems of high cost, difficult treatment, easy introduction of impurities, etc. The effect of improving yield rate and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

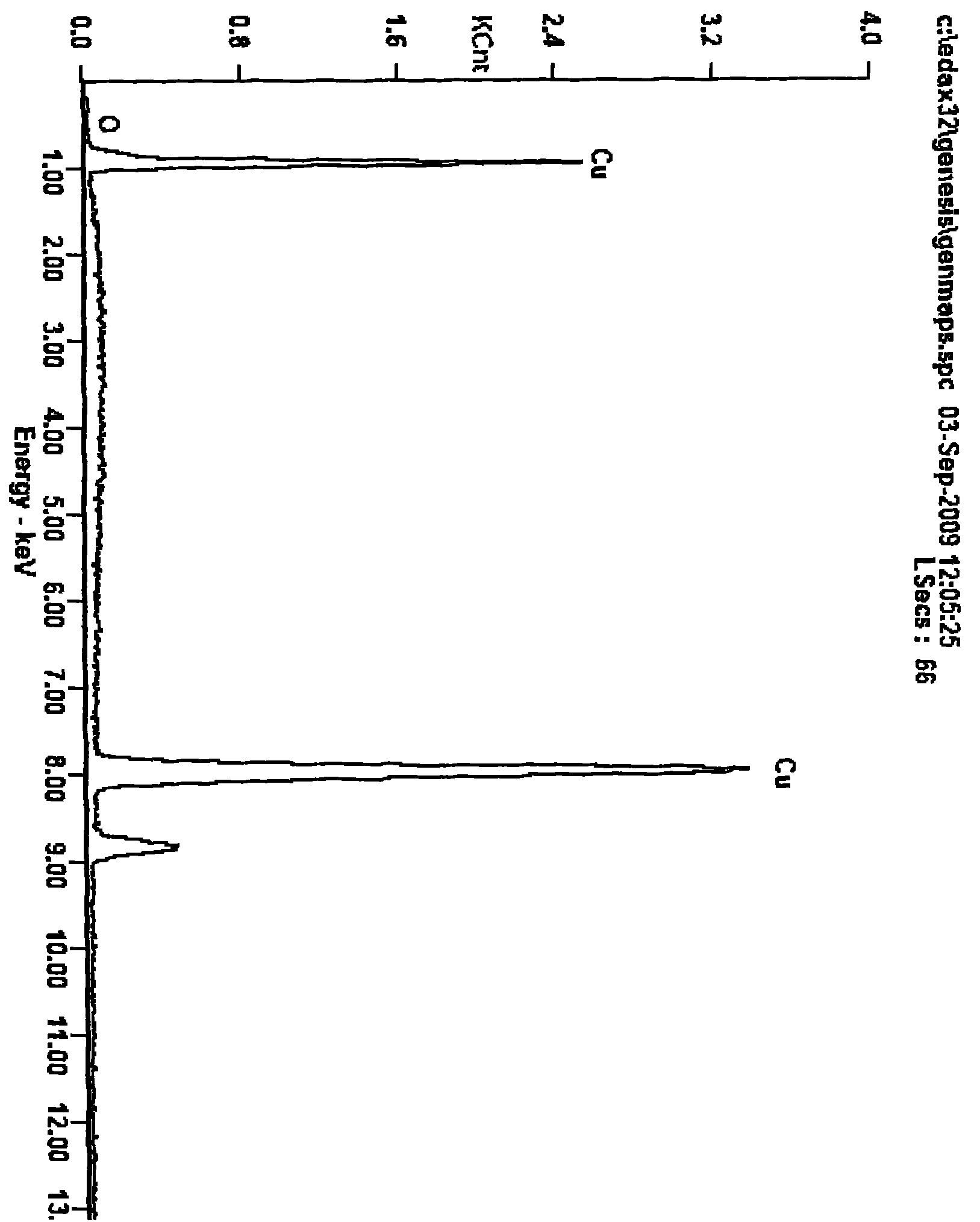

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of 500 grams of submicron copper powder

[0031] Prepare as follows:

[0032] (1), prepare 20000ml of sulfate solution, dissolve ferrous sulfate with water, so that the total concentration of sulfate radical and ferrous ion contained in it is 500g / l;

[0033] (2), prepare 2000ml of colloidal solution, add water and stir and mix in the water-soluble organic matter and be mixed with the colloidal solution that concentration is 100g / L, described water-soluble organic matter is selected from the combination of glucose, citric acid, water-soluble starch, three total weights are 200 grams, the relationship between mutual proportions is not limited;

[0034] (3), after mixing the two solutions of steps (1) and (2), add industrial sulfuric acid, adjust the pH of the solution to 0.8, and the specific gravity of the solution is 1.32, stir and mix, and heat up to 55 ° C;

[0035] (4), in step (3) solution, add degreasing back iron sheet, produce fresh highl...

Embodiment 2

[0038] Example 2 Preparation of 1000 grams of micron copper powder

[0039] Prepare as follows:

[0040] (1) Prepare 30,000ml of sulfate solution. Dissolve soluble sulfate in water so that the total concentration of sulfate and metal cations, namely aluminum ions, ferrous ions, and manganese ions, is 250g / L. Since aluminum sulfate, ferrous sulfate, manganese sulfate, the ratio of the three is not limited;

[0041] (2), prepare colloidal solution 2000ml, add water and stir and mix in the water-soluble organic matter and be mixed with the colloidal solution that concentration is 100g / L, described water-soluble organic matter is selected from urea, water-soluble starch combination, both gross weights are 200 grams, The mutual proportional relationship is not limited;

[0042](3), after mixing the two solutions of steps (1) and (2), add industrial sulfuric acid to adjust the pH of the solution to 0.1, and the specific gravity of the solution is 1.28; then stir and mix and heat u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com