Preparation method for triazine hyperbranched macromolecular carbon forming agent

A technology based on macromolecules and triazines, which is applied in the field of preparation of triazine hyperbranched macromolecular char-forming agents to achieve the effects of short reaction time, broad application prospects and continuous reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

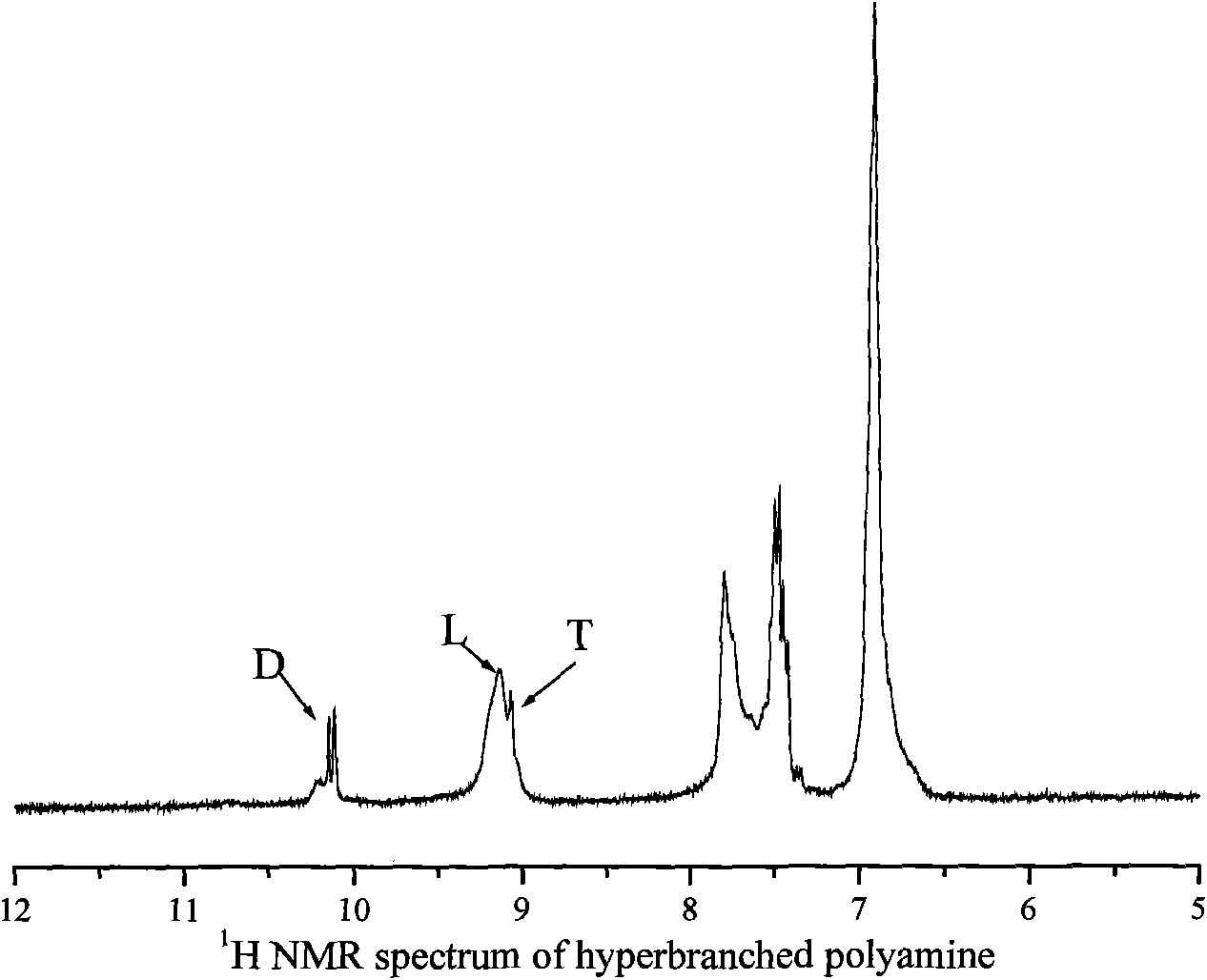

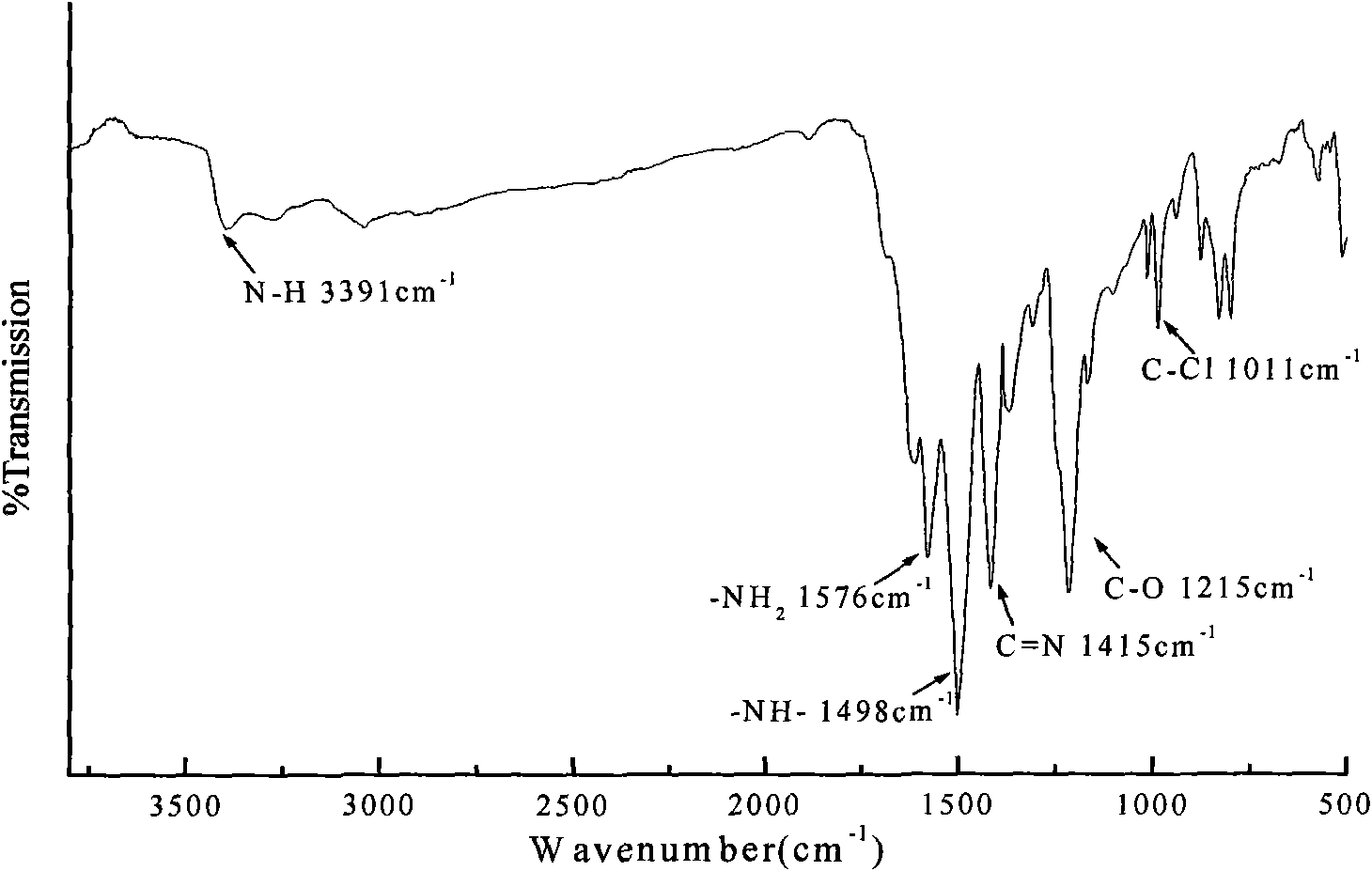

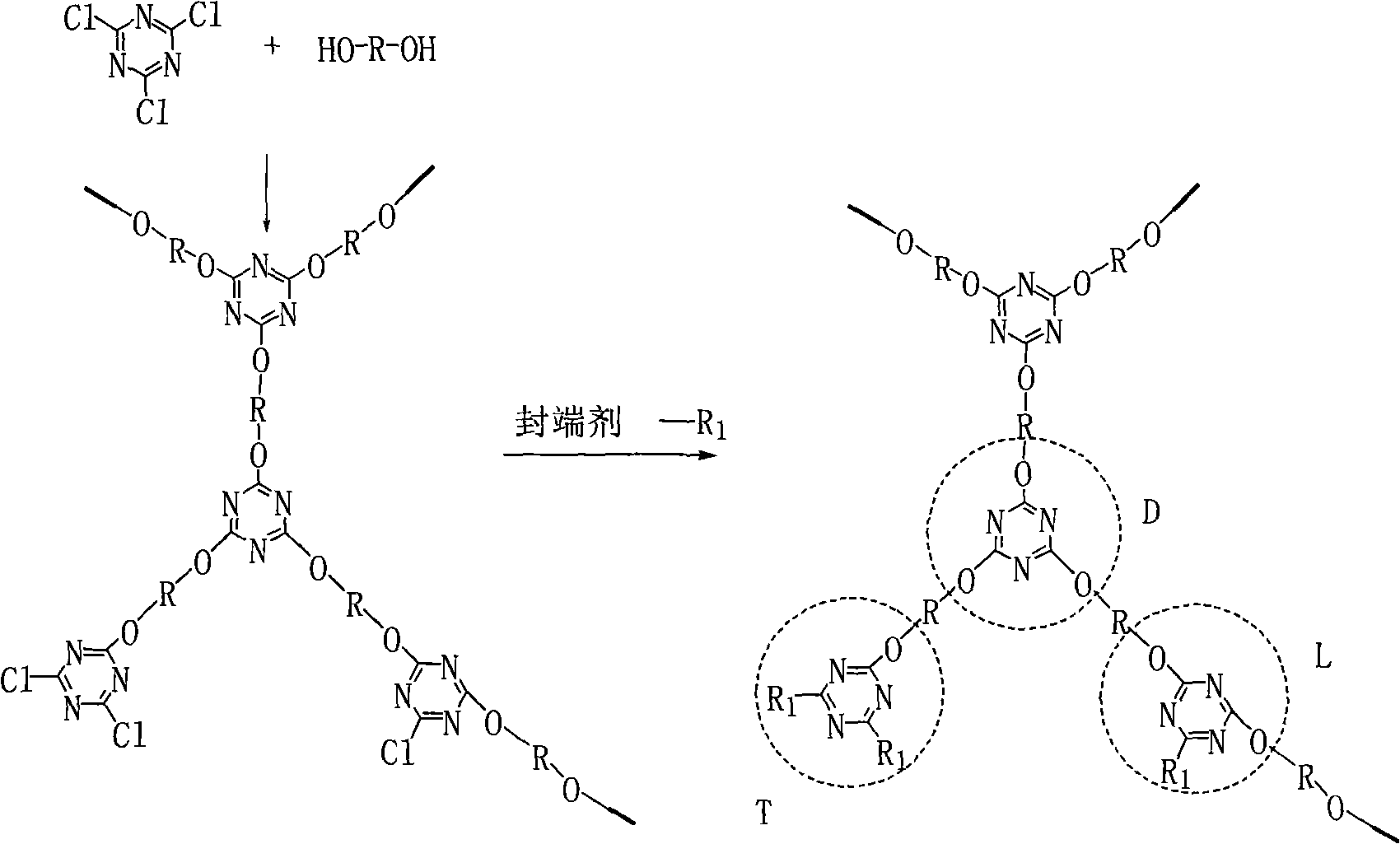

[0029] Example 1: Dissolve 0.03 mol of 4,4-diaminodiphenyl ether and 0.1 mol of triethylamine in 25 ml of N,N-dimethylformamide (DMF), and stir at 0.5°C for 0.5 Hour. Dissolve 0.02 mol of cyanuric chloride in 50 ml of DMF, add dropwise to the system at this temperature, and continue to react at this temperature for 3 hours, raise the temperature to 90°C, react for 6 hours, and then add 0.1 mol of aniline, heated up to 100°C, reacted for another 2 hours, stopped stirring, precipitated in 1000 ml of water, washed twice with 50 ml of ether and 100 ml of acetone, filtered, and dried in vacuum at 70°C for 20 hours to obtain Hyperbranched polyamide triazine char forming agent, in nitrogen atmosphere, the weight loss is 3% at 300°C, and the carbon content is 72% at 600°C. figure 1 It is the H NMR spectrum of the product in Example 1. Three different types of tertiary amine hydrogen atoms can be observed in the figure, and their chemical shifts are respectively δ=10.15ppm, δ=9.15ppm,...

Embodiment 2

[0030]Embodiment 2: 0.04mol of 4,4-diaminodiphenylmethane and 0.3mol of N,N-diisopropylethylamine are dissolved in 40 milliliters of N,N-dimethylacetamide (DMAC), nitrogen The mixture was stirred at 5° C. for 0.5 hour in the atmosphere. Dissolve 0.06 mol of cyanuric chloride in 50 ml of DMF, add dropwise to the system at this temperature, and continue to react at this temperature for 4 hours, raise the temperature to 110°C, react for 7 hours, and then add 0.35 mol of 1-naphthylamine, heated to 120°C, reacted for another 2 hours, stopped stirring, precipitated in 800 ml of methanol, washed 3 times with 100 ml of water and 100 ml of acetone, filtered, and dried in vacuum at 100°C for 5 After 1 hour, a hyperbranched polyamide triazine char-forming agent was prepared. In a nitrogen atmosphere, the weight loss at 300° C. was 4%, and the carbon content at 600° C. was 67%.

Embodiment 3

[0031] Example 3: 0.07 mol of hexamethylenediamine and 0.5 mol of triethylamine were dissolved in 60 ml of tetrahydrofuran (THF), and stirred at 15° C. for 0.5 hour in a nitrogen atmosphere. Dissolve 0.07 mol of cyanuric chloride in 80 ml of THF, add dropwise to the system at this temperature, and continue to react at this temperature for 3 hours, raise the temperature to 85°C, react for 7 hours, and then add 0.3 mol of 1-naphthylamine, heated to 95°C, reacted for another 3 hours, stopped stirring, precipitated in 1500 ml of water, washed twice with 200 ml of methanol and 100 ml of toluene, filtered, and dried in vacuum at 50°C for 60 hours , to prepare a hyperbranched polyamide triazine char-forming agent, in a nitrogen atmosphere, the weight loss at 300°C is 6%, and the carbon content at 600°C is 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com