Method for preparing nitrogen-doped TiO2 photocatalytic film

A technology of photocatalytic thin film and nitrogen doping, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. It can solve the problem that it is difficult to obtain the amount of nitrogen doping, and the method is simple and easy to degrade Efficiency improvement and photocatalytic performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

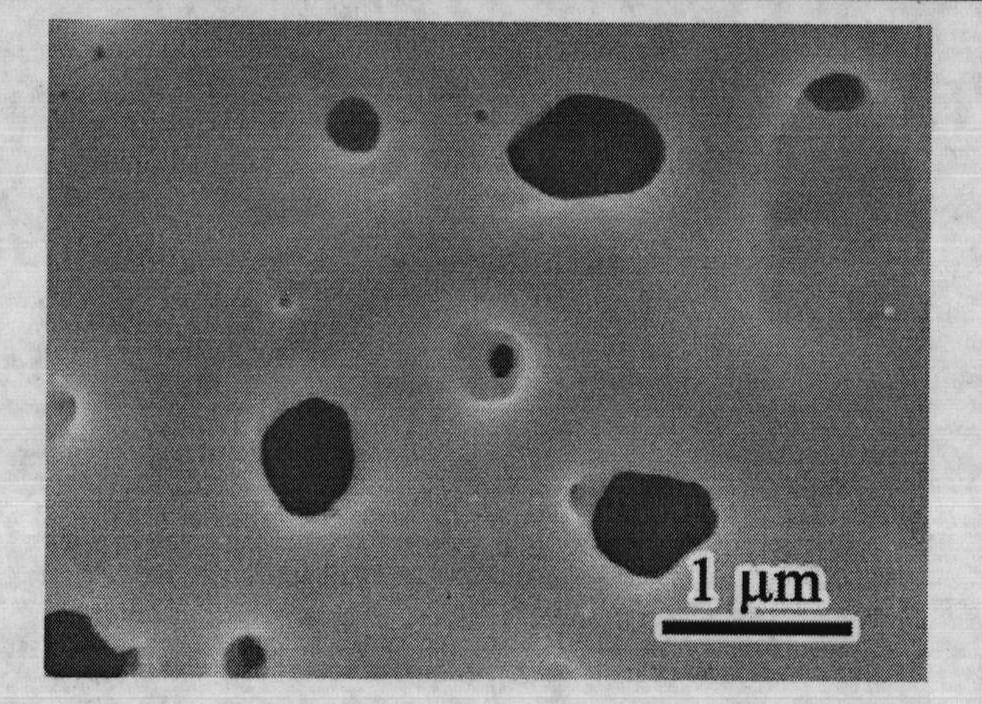

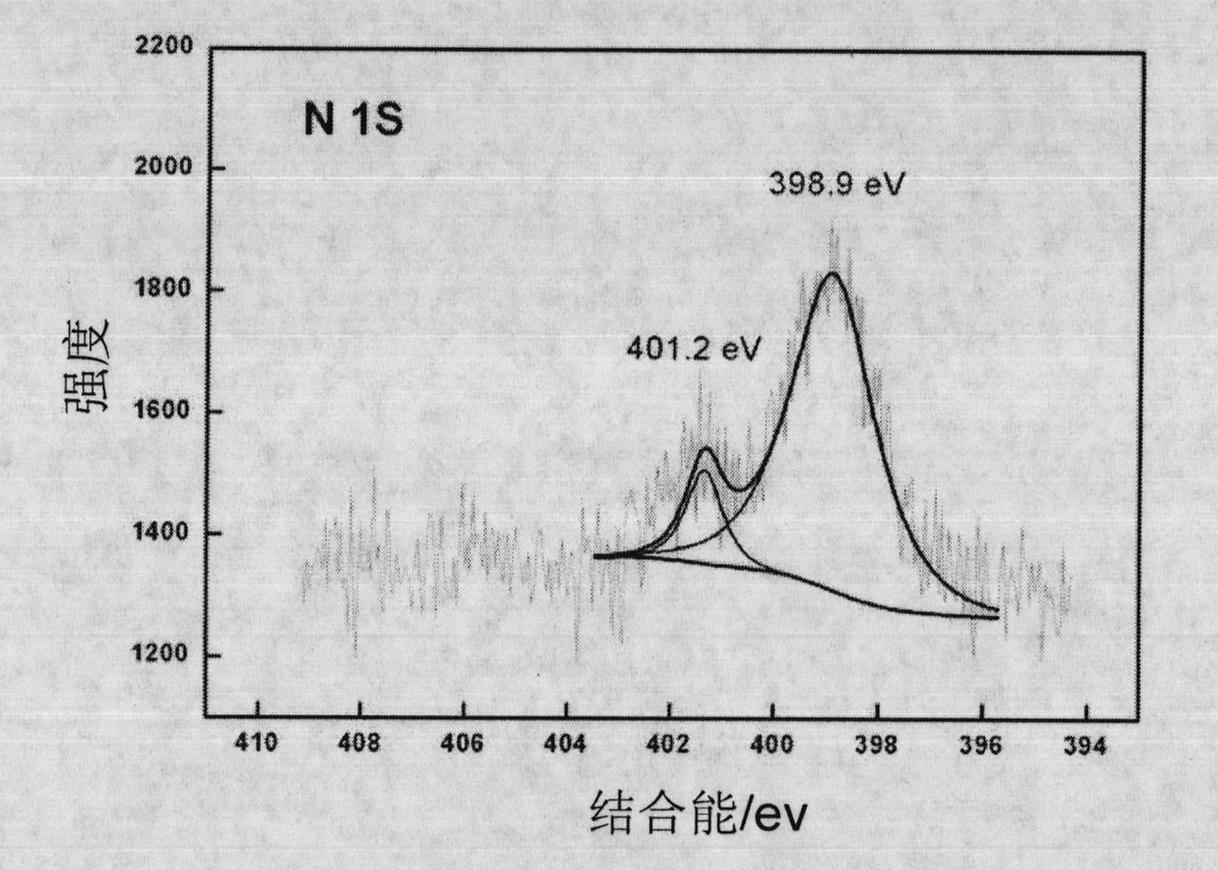

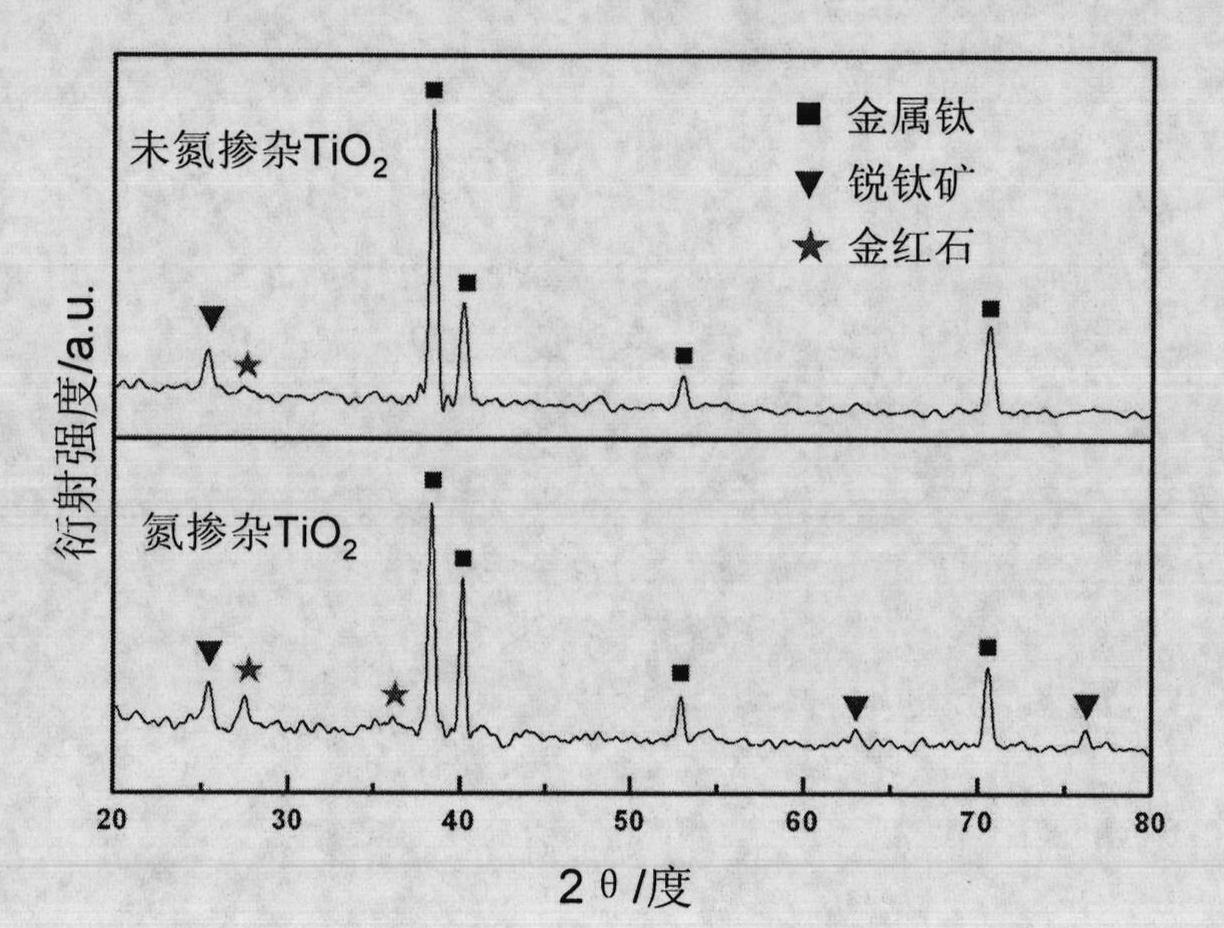

[0027] Embodiment 1: put the polished metal titanium or titanium alloy into the LD-70 ion nitriding furnace with ammonia gas and the furnace cavity maintaining negative pressure, the metal titanium or titanium alloy is used as the cathode material, and the furnace body is used as the anode Material, apply a voltage between the cathode and anode to produce glow discharge, control the temperature at 700°C, and hold the temperature for 15h; when the temperature drops to 150°C, take out the sample from the ion nitriding furnace; weigh 20g of anhydrous sodium carbonate, 5g of nonaqueous Add 1000ml of deionized water to dissolve sodium silicate and place it in the reaction tank as the electrolyte; use electric mixer to stir and circulate condensed water to control the temperature of the whole system in the reaction tank within 40 °C; Metal titanium or titanium alloy is used as the anode, and the stainless steel plate is used as the cathode material. The pulse voltage is slowly increa...

Embodiment 2

[0029] Embodiment 2: put the polished metal titanium or titanium alloy into the LD-70 ion nitriding furnace with ammonia gas and the furnace cavity maintaining negative pressure, the metal titanium or titanium alloy is used as the cathode material, and the furnace body is used as the anode Material, apply a voltage between the anode and cathode to produce glow discharge, control the temperature at 900°C, and hold the temperature for 10h; when the temperature drops to 100°C, take out the sample from the ion nitriding furnace; weigh 15g of anhydrous sodium carbonate, 10g of nonaqueous Add 1000ml of deionized water to dissolve sodium silicate and place it in the reaction tank as the electrolyte; use electric mixer to stir and circulate condensed water to control the temperature of the whole system in the reaction tank within 40 °C; Metal titanium or titanium alloy is used as the anode, and the stainless steel plate is used as the cathode material. The pulse voltage is slowly incre...

Embodiment 3

[0031] Embodiment 3: put the polished metal titanium or titanium alloy into the LD-70 ion nitriding furnace with ammonia gas and the furnace cavity maintaining negative pressure, the metal titanium or titanium alloy is used as the cathode material, and the furnace body is used as the anode Material, apply a voltage between the cathode and anode to produce glow discharge, control the temperature at 850°C, and hold the temperature for 5 hours; when the temperature drops to 180°C, take out the sample from the ion nitriding furnace; weigh 25g of anhydrous sodium carbonate, 15g of nonaqueous Add 1000ml of deionized water to dissolve sodium silicate and place it in the reaction tank as the electrolyte; use electric mixer to stir and circulate condensed water to control the temperature of the whole system in the reaction tank within 40 °C; Metal titanium or titanium alloy is used as the anode, and the stainless steel plate is used as the cathode material. The pulse voltage is slowly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com