Method for harmlessly treating trash flying ash by adopting trash-burning process

A technology of harmless treatment and garbage incineration, which is applied in the direction of solid waste removal, etc., can solve problems such as inability to make harmless treatment, and achieve the effect of low treatment cost, simple process and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

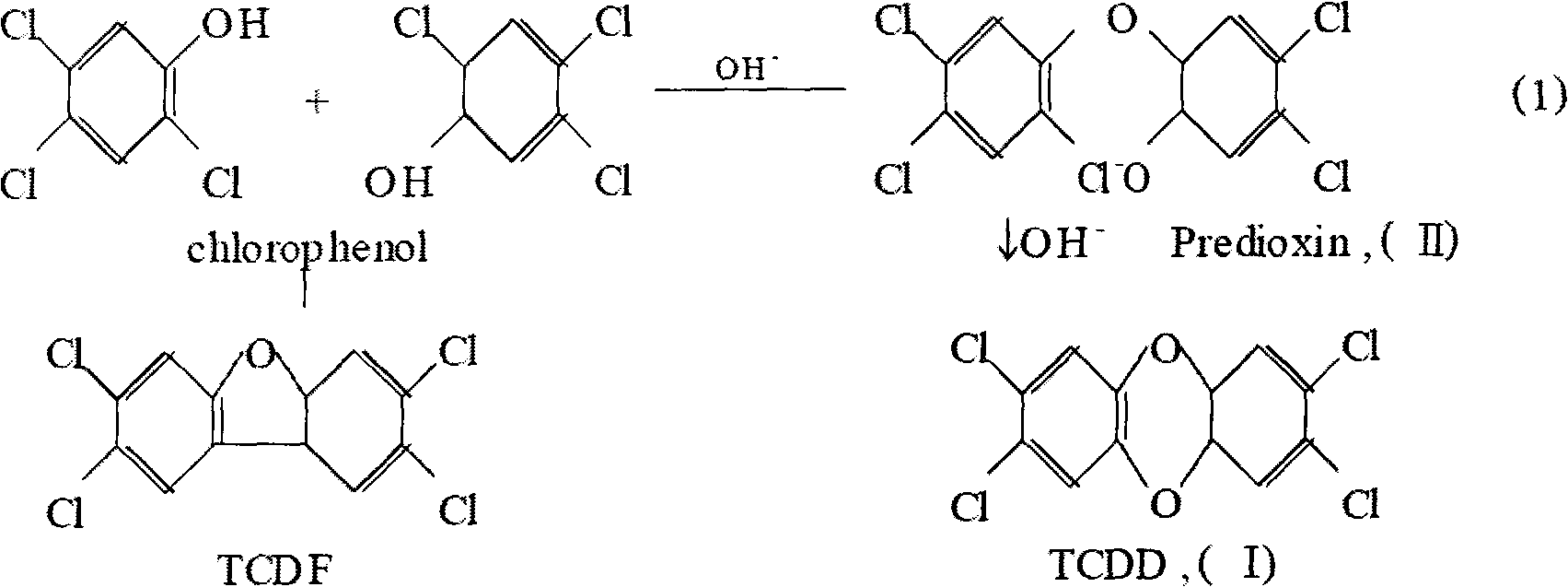

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, 1 kilogram of the weight of ball nucleus raw material, comprises rubbish fly ash 78.%, coal dust 20%, special adhesive 2% (it is made of syrup 50%; Glutinous rice flour 20%; Humic acid 20% and borax 10% composition), using disk granulation technology to make a spherical core with a diameter of 5mm. The raw material of the spherical shell is 2 kg, 98% of garbage slag and 2% of bentonite are used, and the spherical shell is formed outside the spherical core by disc granulation technology, and the diameter of the spherical shell is 10mm.

[0035] The incineration test is carried out in the test furnace; the test atmosphere is an oxidizing atmosphere, liquefied gas is used as fuel, and the green pellets are placed in the furnace for incineration. The whole process simulates the thermal system of waste incineration, the temperature is 850-1000 ℃, and the time is 2 hours. The product was taken out for various tests, and the relevant control indicators were found...

Embodiment 2

[0037] Treatment of garbage fly ash: moisture less than 4%, particle size -200 mesh

[0038] Calculated on the basis of 1 ton of the total amount of ball core raw materials, 0.78 tons of garbage fly ash, 0.2 tons of coal powder and coke powder (the amount of the two can be arbitrarily mixed), 0.02 tons of special adhesive (including 60% syrup; glutinous rice flour 15%; Humic Acid 17%; Borax 8%). After being mixed by the mixer, it enters the disc granulator to produce a spherical core with a diameter of 6 mm. The semi-finished product passed through the vibrating screen is sent to the secondary pelletizing disc by a belt conveyor, and 1.96 tons of garbage slag and 0.04 tons of bentonite are uniformly mixed. The mixture is sent to the secondary pelletizing disk for shell making. The diameter of the spherical shell is 13mm. After the green balls are formed, they enter the sealed special transport vehicle and send them to the garbage incinerator. Sample, tested: related control i...

Embodiment 3

[0040] Treatment of garbage fly ash: moisture less than 4%, particle size -200 mesh

[0041] Assuming that the total amount of spherical core raw materials is 10 tons, take 6.9 tons of garbage fly ash, 3 tons of coke powder or coal powder (-200 mesh), and 0.1 tons of humic acid; after being mixed by a mixer, enter the disc granulator to make The semi-finished product with a diameter of 8mm and passed through the vibrating screen is sent to the secondary pelletizing disc by a belt conveyor. At the same time, 19.6 tons of garbage slag and 0.4 tons of humic acid are evenly mixed and sent to the secondary pelletizing disc for shell making. , the diameter of the spherical shell is 16mm. After the raw ball is formed, it enters the sealed special transport vehicle and sends it to the garbage incinerator. 1ng TEQ / Nm 3 , hexavalent chromium <5mg / L, and other heavy metals -Hg<0.1mg / L, Cd<1mg / L, Pb<5mg / L) all meet the national environmental protection requirements and achieve the purpos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com