Screening and construction method for composite microbial system for rapidly degrading rice straw and composite microbial system

A technology of rice straw and construction method, which is applied in the field of microbial screening, can solve the problems of few research reports and achieve good decomposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

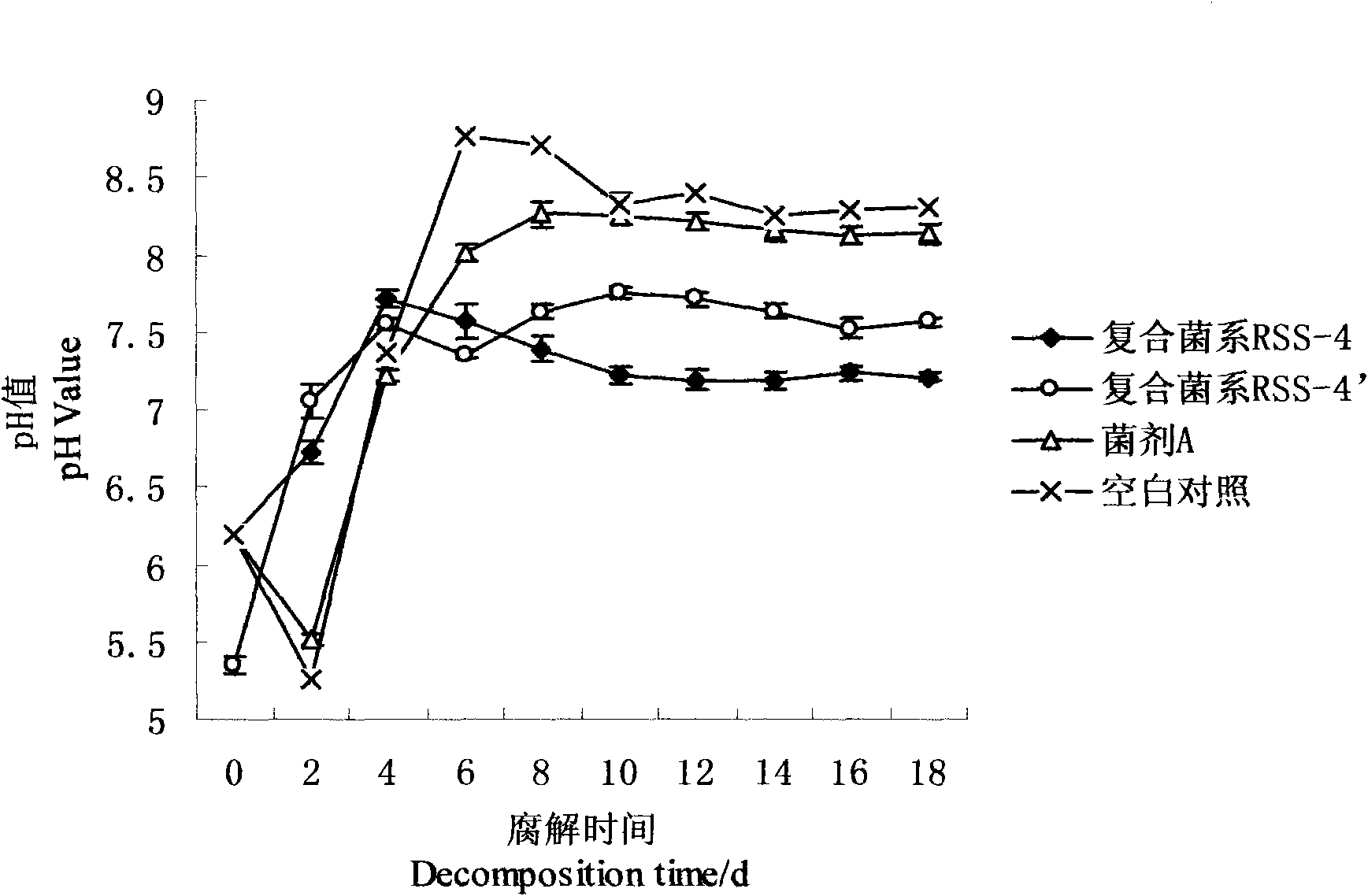

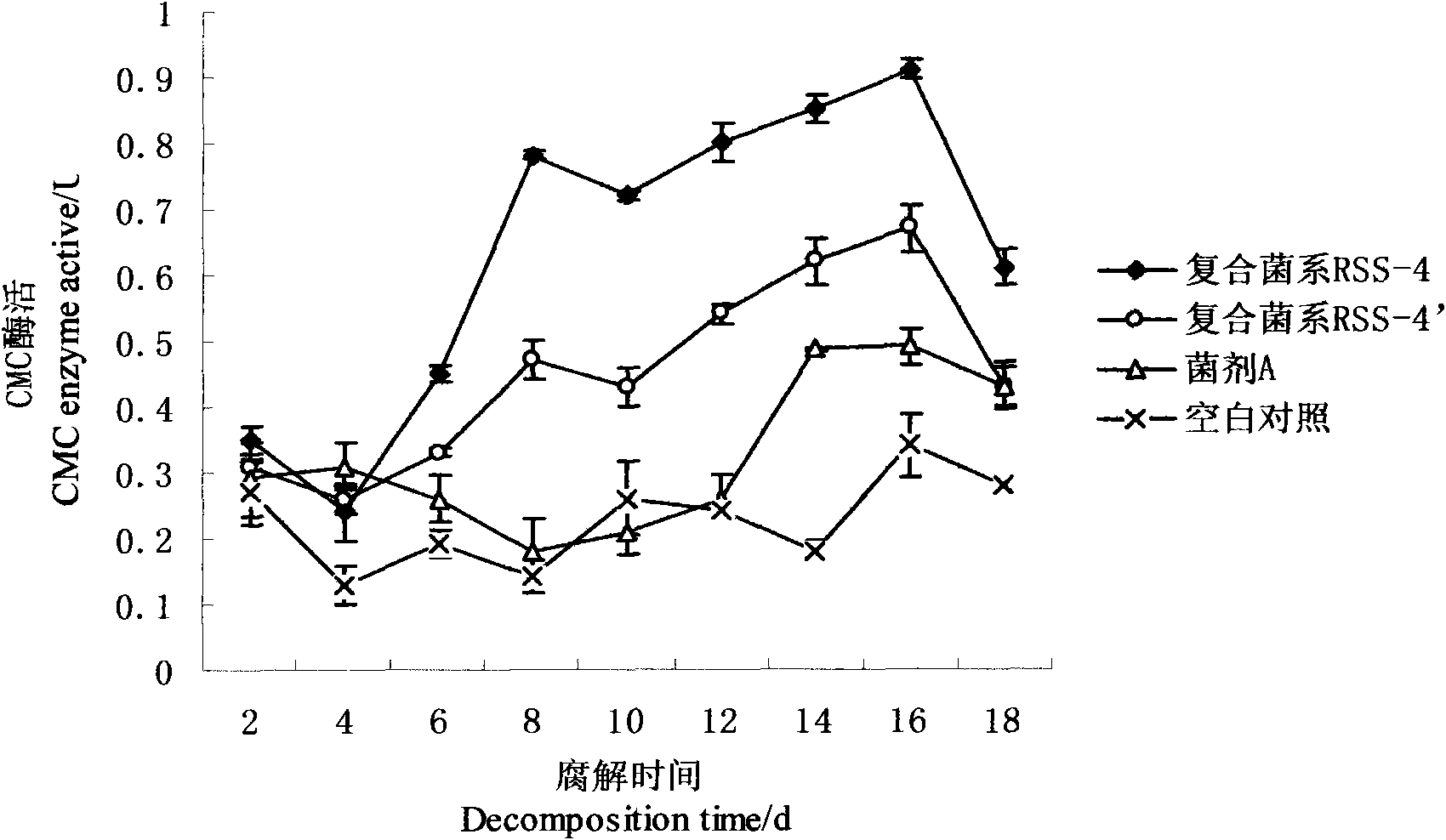

[0035] A method for screening and constructing a compound strain capable of rapidly degrading rice straw includes the following steps:

[0036] (1) Preparation of solid medium:

[0037] Rice straw powder (the rice straw is crushed and passed through a 60-mesh sieve) 75g, bran (after crushed and passed through a 60-mesh sieve) 30g, nutrient salt solution 100ml, stirred evenly, natural pH, and sterilized and non-sterilized ; Wherein the nutrient salt solution contains (NH4) 2SO4 2%, KH2PO4 0.1%, MgSO4.7H2O 0.5%, CaCl2 0.01%, NaCI 0.01%, FeSO4.7H2O 0.005%, MnS04.H2O 0.0016%, ZnSO4. 7H2O 0.0014% and CoCl 20.002%.

[0038] (2) Construction of strain pool:

[0039] Take twelve 5L plastic buckets, and fill them with 5kg paddy soil collected from Changping Farm of the Institute of Agricultural Sciences, Chinese Academy of Agricultural Sciences. Keep the moisture content at about 60%. Stir it evenly. Use rice straw as the only carbon source. Add urea and diphosphate. Potassium hydrogen and p...

Embodiment 2

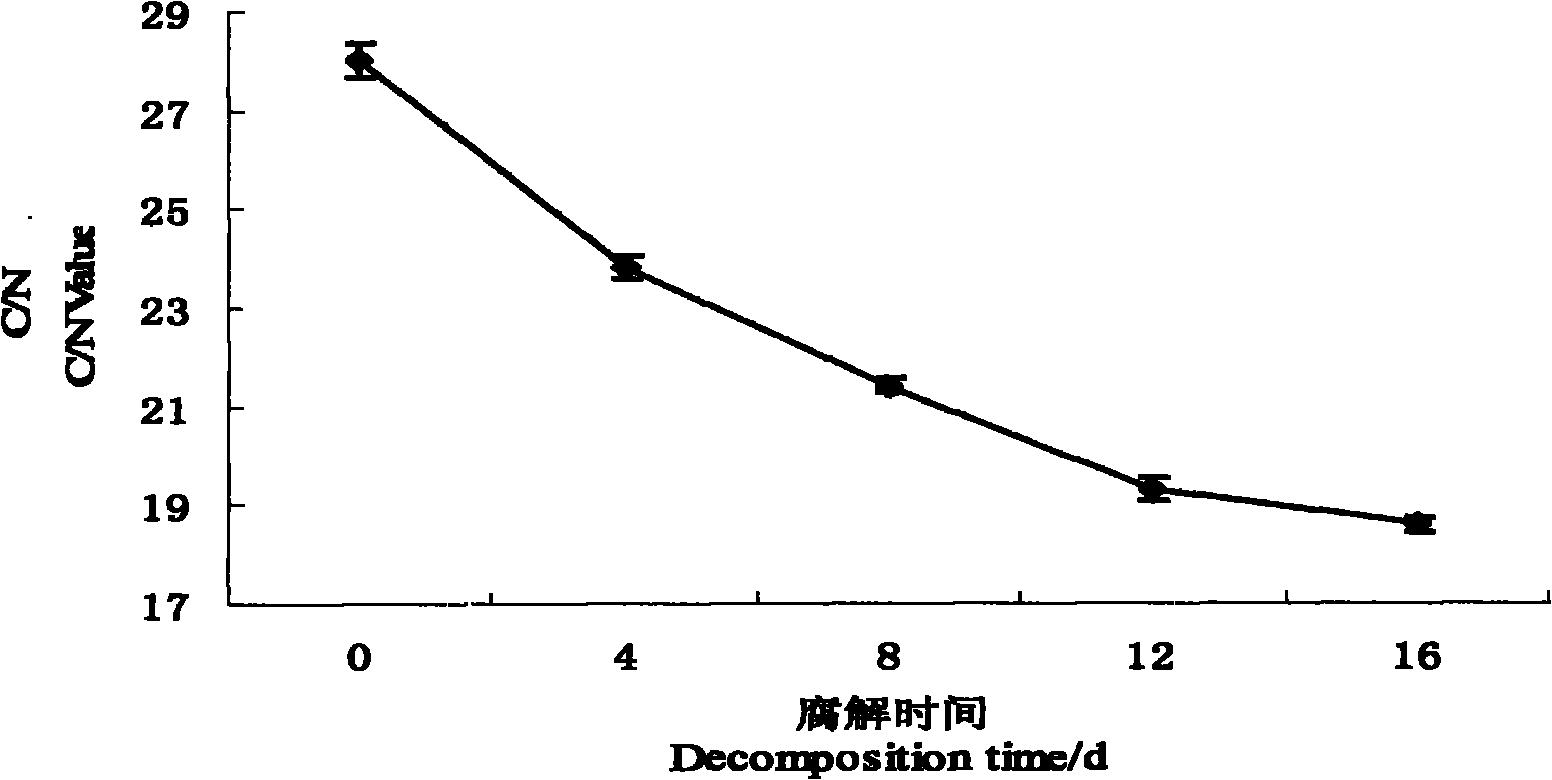

[0044] This embodiment is exactly the same as embodiment 1, the only difference is that in step (3), the addition of inorganic nitrogen is used to adjust the C / N value in the solid medium to 28.

Embodiment 3

[0046] This embodiment is exactly the same as embodiment 1, except that in step (3), the addition of bran and inorganic nitrogen is used to adjust the C / N value of the solid medium to 28.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com