Method for preparing Griflola frondosa proteoglycan

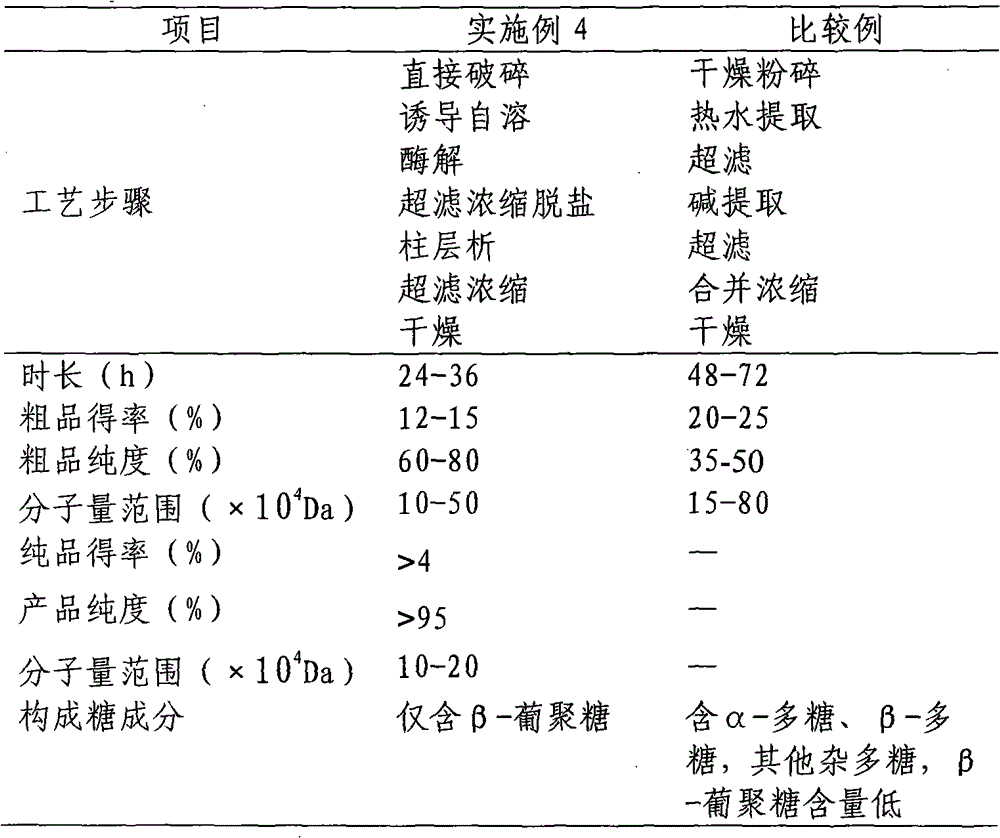

A technology for proteoglycan and Grifola frondosa, applied in the field of medicine, can solve the problems of low content, restricting the activity of Grifola frondosa proteoglycan, and environmental protection pressure, and achieves the advantages of single processing steps, shortened processing time, and alleviation of environmental protection pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Take 10L of Grifola frondosa fermented liquid, wherein the content of dry mycelia is 2% (w / v), add 1g of magnesium sulfate, 20g of calcium carbonate, homogenize with a homogenizer, mix thoroughly, and adjust the pH of the solution to 4.5 with acetic acid , heat up to 50°C for 4 hours; use sodium hydroxide to adjust the pH of the autolyzed liquid to 8.5, add 20 g of alkaline protease, enzymolyze at 50°C for 4 hours, rapidly raise the temperature to 90°C for 20 minutes, and after cooling, 4000r Centrifuge at a speed of 10 min / min, collect the centrifuged supernatant, microfilter and ultrafilter the supernatant, adjust the ionic strength of the ultrafiltrate and the concentration of Grifola frondosa proteoglycan, use DEAE-Sepharose FF medium for chromatographic column chromatography, and then ultra- Filtration, freeze-drying to obtain Grifola frondosa proteoglycan. The Grifola frondosa proteoglycan content of the product is 96%, and the yield is 4.2% (calculated as dry bac...

Embodiment 2

[0043] Get 1500g of the fresh fruiting bodies of Grifola frondosa, which contains 80% moisture, and crush it to a particle size of 0.1-0.3cm with a crusher, add purified water to settle to 10L, and adjust to 3% (w / v) equivalent to the dry cell content, Add 0.5g of magnesium sulfate and 10g of calcium chloride, homogenize with a homogenizer, mix thoroughly, adjust the pH of the solution to 5.0 with hydrochloric acid, and heat up to 50°C for 6 hours to autolyze; use potassium hydroxide to adjust the pH of the autolyzed solution to 8.0, Add 20g of papain and 20g of cellulase, enzymatically hydrolyze at 50°C for 6h, rapidly heat up to 90°C to inactivate for 10min, after cooling, centrifuge at 13000r / min for 10min, collect the centrifuged supernatant, microfiltration and ultrafiltration of the supernatant, Adjust the ionic strength of the ultrafiltrate and the concentration of the grifola frondosa proteoglycan, adopt DEAE-Sephace chromatographic column chromatography, then ultrafilt...

Embodiment 3

[0045] Take 10L of Grifola frondosa fermentation broth, equivalent to 2% (w / v) of dry mycelium content, add 10g of magnesium sulfate, 5g of calcium carbonate, use a homogenizer to homogenize, mix well, and adjust the pH of the solution to 5.0 with citric acid , heat up to 50°C and autolyze for 8 hours; adjust the pH of the autolyzed liquid to 7.5 with sodium carbonate, add 20g of papain, enzymolyze at 50°C for 4 hours, rapidly raise the temperature to 90°C to inactivate for 20min, after cooling, rotate at 10000r / min Centrifuge for 10 minutes, collect the centrifuged supernatant, microfilter and ultrafilter the supernatant, adjust the ionic strength of the ultrafiltrate and the concentration of proteoglycan from Grifola frondosa, use Q-Sepharose FF column chromatography, then ultrafilter and freeze-dry to obtain ash tree flower proteoglycan. The proteoglycan content of the product is 97%, the yield is 4.8% (based on the dry weight of the bacteria), the sugar content in the prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com