Method for recycling DMAC (Dimethyl Acetylamide) from waste spandex stock solution

A technology of waste stock solution and spandex, applied in the field of N recycling, can solve the problems of complex process, increase solvent loss, secondary pollution, etc., and achieve the effect of no pollution in recovery rate, simple process and no loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

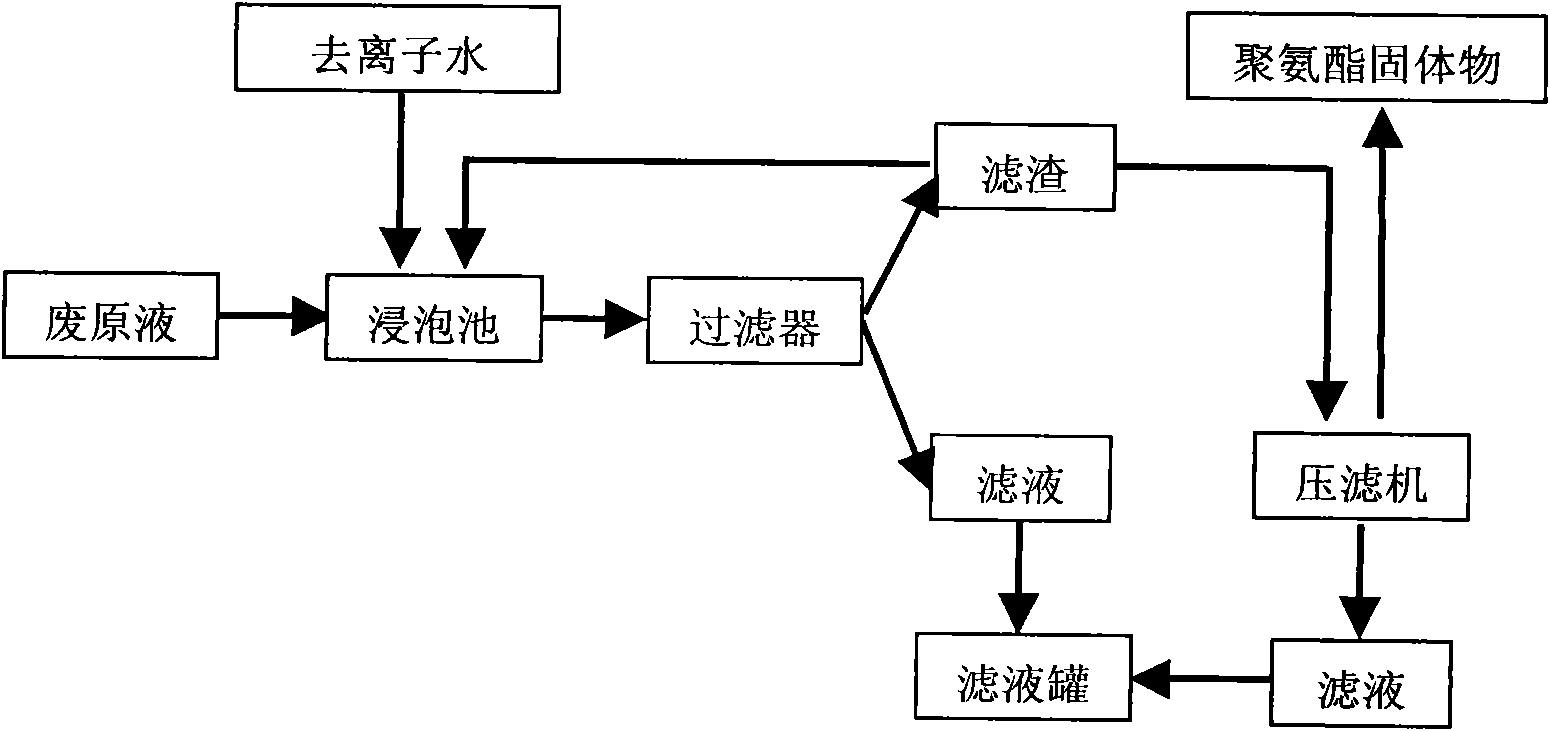

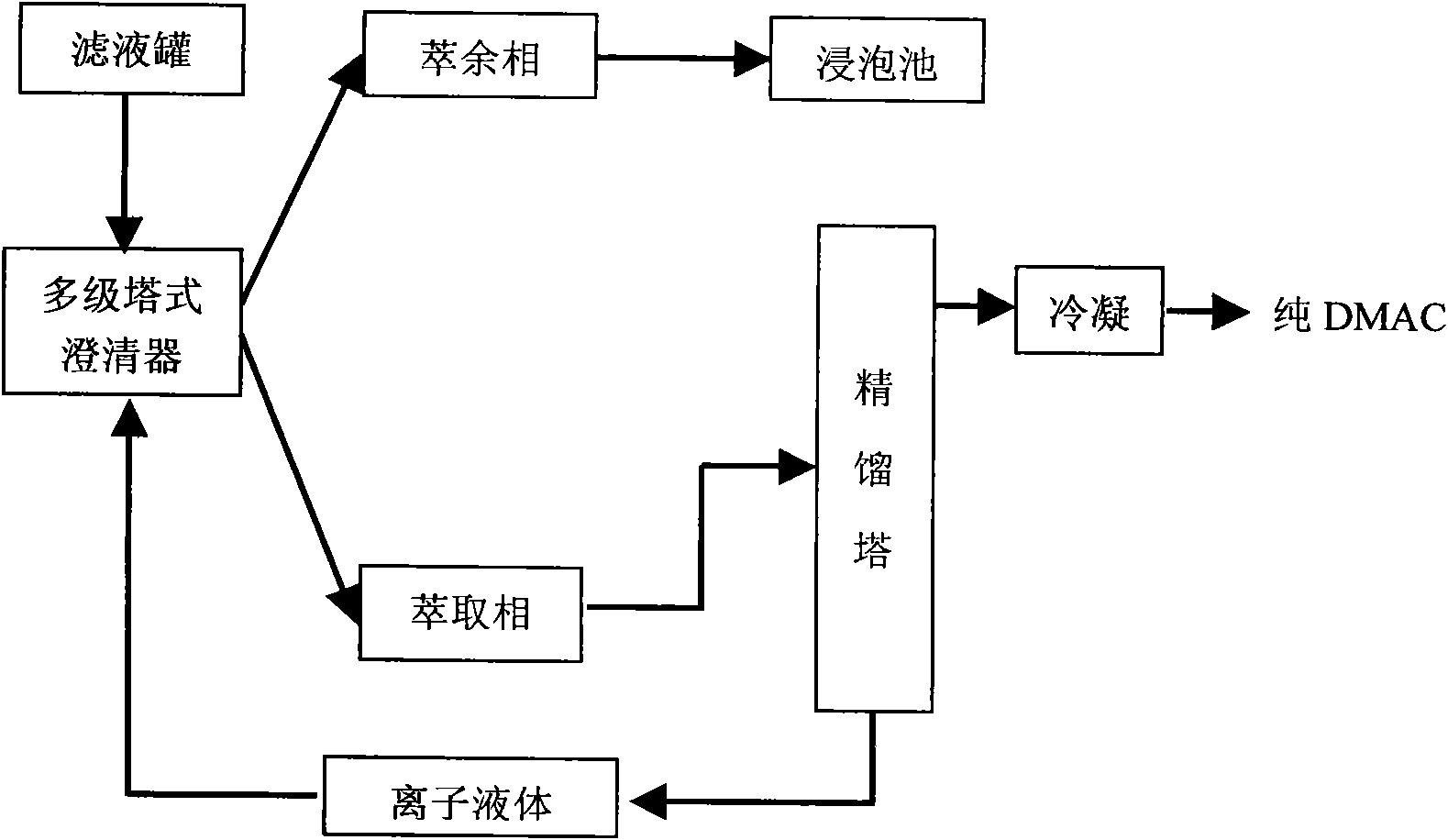

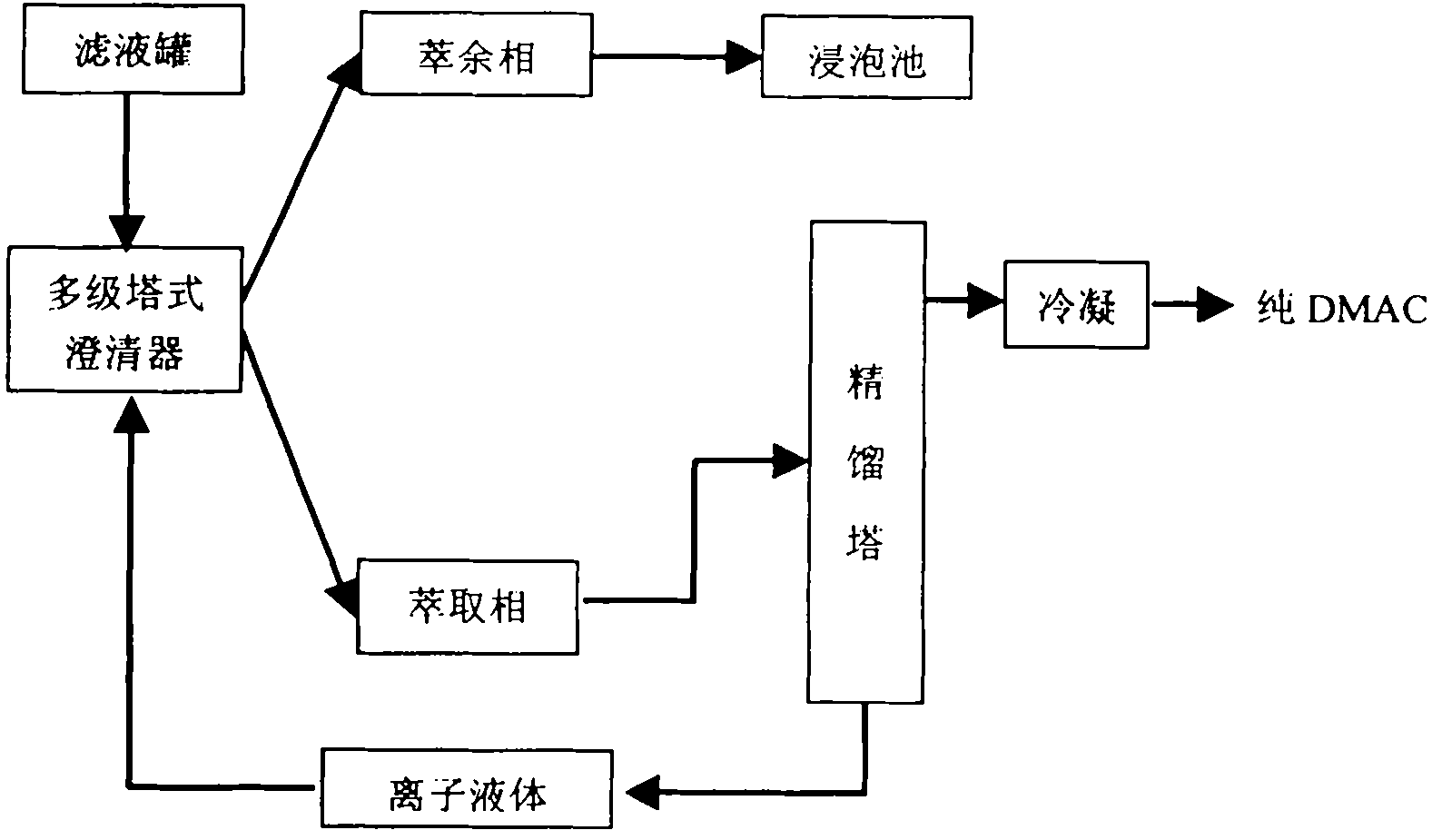

[0028] see figure 1 with figure 2 , figure 1 It is a flow chart of the water treatment and separation process of spandex waste stock solution of the present invention. figure 2 It is a flow chart of the DMAC recovery process in the spandex waste stock solution of the present invention. Depend on figure 1 with figure 2 As can be seen, the method for reclaiming DMAC from spandex waste stock solution includes the following processes:

[0029] First, prepare the ionic liquid

[0030] Mix methylimidazole and 3-chloropropyl ether evenly at a molar ratio of 1:1, reflux in a water bath at 85-95°C for 20-30 hours under nitrogen protection, and then wash with silicone or ether to remove unconverted reactants , to remove silicone or ether by rotary evaporation. Then add potassium hexafluorophosphate (KPF 6 ), heated to 85-95°C for 15 hours, cooled, washed with deionized water and dried, and finally evaporated at 85°C for 10 hours to remove impurities to obtain an ionic liquid....

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com