Solar cell rear panel, preparation method thereof and solar cell module using rear panel

A solar cell and backplane technology, which is applied in electrical components, chemical instruments and methods, circuits, etc., can solve the problems of solar cells such as weather resistance, ultraviolet resistance, insulation degradation, insufficient bonding strength, and affecting the life of solar cells. Achieve excellent dimensional stability and not easy to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention provides a method for preparing the above-mentioned solar cell backsheet, the method comprising:

[0023] (1) Substrates are carried out sequentially, static removal treatment, surface plasma treatment or surface corona treatment to obtain a surface-treated substrate;

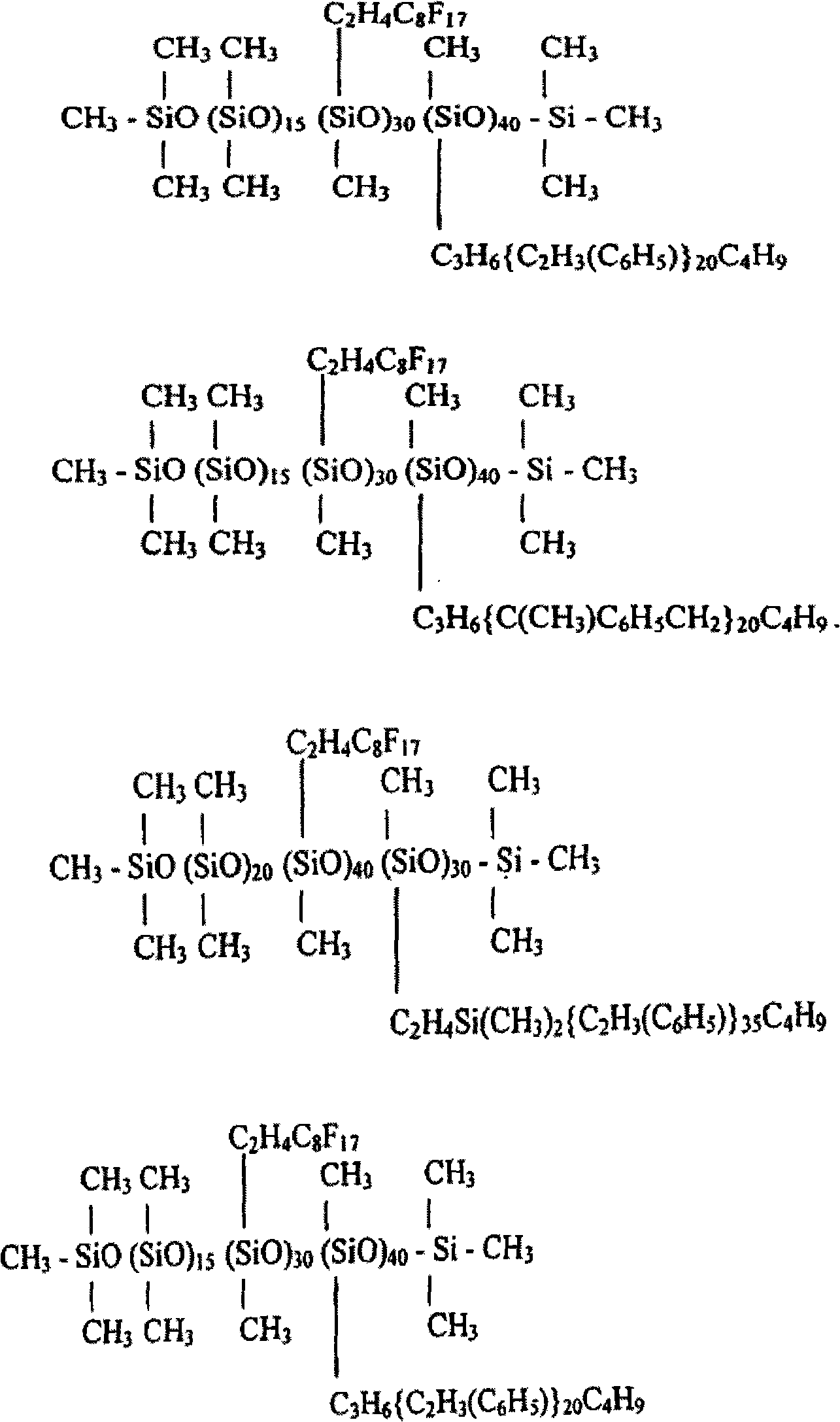

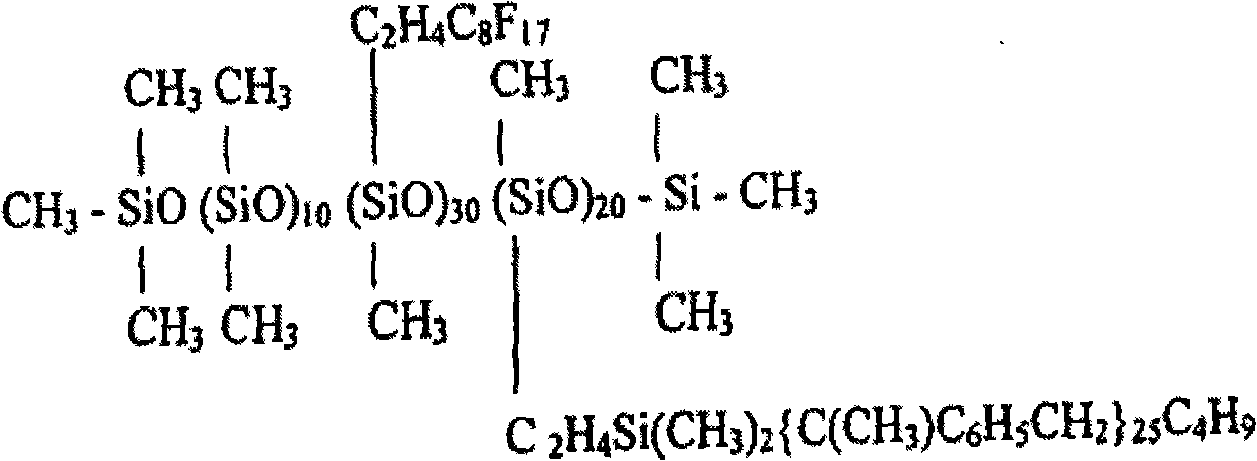

[0024] (2) Weigh fluorocarbon resin, solvent, fluorosiloxane, crosslinking agent, filler (obtained by trifluoropropylmethylcyclotrisiloxane (D3F) polymerization, raw material from Dowcorning Dow Corning) in proportion , Dissolving fluorocarbon resin and fluorosilicone in solvent, then adding crosslinking agent and filler to form mixed emulsion;

[0025] (3) directly coating the mixed emulsion obtained in step (2) on at least one side of the surface-treated substrate obtained in step (1), under heating conditions, a crosslinking and curing reaction occurs to obtain a solar cell backplane.

[0026] The substrate material mentioned in the present invention is selected from one of pol...

Embodiment 1

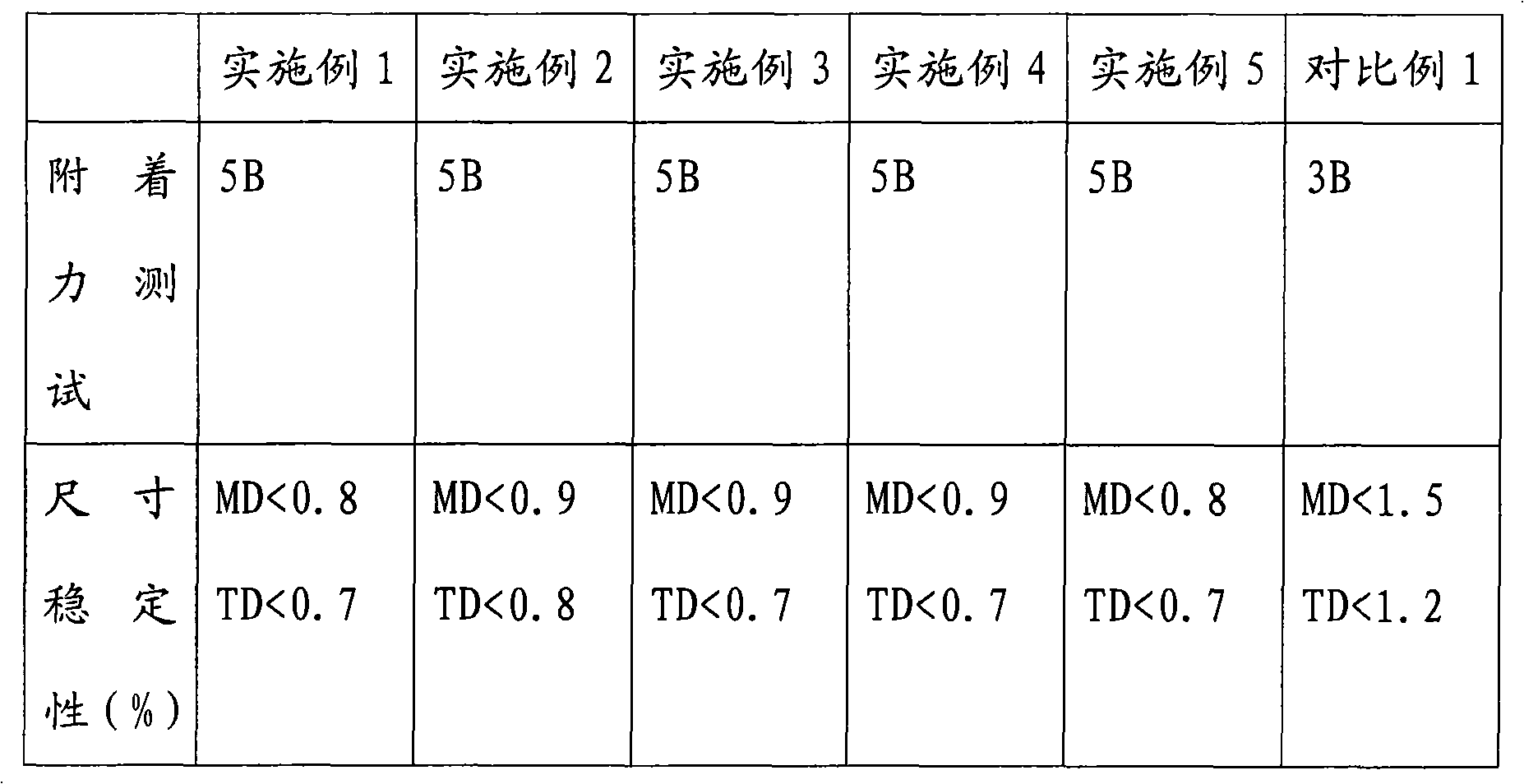

[0037] This embodiment is used to illustrate the solar battery back sheet provided by the present invention and its preparation method.

[0038] Put the polyethylene terephthalate substrate with a thickness of 250 microns into a corona machine (Techmach company) to carry out double-sided surface treatment, and the corona treatment intensity is 80watt / m 2 / min, the surface energy of the film before treatment is 30dyn / cm, and the surface energy after treatment is 55dyn / cm.

[0039] Take by weighing 25g of polyvinyl fluoride, 10g of fluorosilicone, 6g of polyisocyanate, 40g of propylene glycol methyl ether, and 15g of titanium dioxide, first polyvinyl fluoride and fluorosiloxane are dissolved in propylene glycol methyl ether, Stir at a speed of 150 rpm, stir for 30 minutes, add polyisocyanate and titanium dioxide, mix and stir, the stirring speed is 100 rpm, and the stirring time is 20 minutes to obtain a mixed emulsion;

[0040] Use a self-made coater for the mixed emulsion, an...

Embodiment 2

[0042] The PET base film with a thickness of 250 microns is treated on both sides with a special corona treatment equipment, and the corona treatment intensity is 90watt / m 2 / min, the surface energy of the film before treatment is 30dyn / cm, and the surface energy after treatment is 60dyn / cm.

[0043] Weigh 30g of polyvinylidene fluoride (PVDF), 8g of fluorosiloxane,? 5 g of polyisocyanate, 50 g of dimethylacetamide, 8 g of titanium dioxide. First dissolve polyvinylidene fluoride and fluorosiloxane in dimethylacetamide, stir at a speed of 100 rpm, stir for 30 minutes, add polyisocyanate and titanium dioxide, mix and stir, and stir at a speed of 80 rpm , the stirring time is 30min, and the mixed emulsion is obtained;

[0044] Use a self-made applicator for the mixed emulsion, and the coating method can be coated on one side of a polyethylene terephthalate substrate with a size of 40mm×30mm×20um, and the coating thickness is 100um. The substrate covered with the mixed emulsion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com