Application method for cephalosporin C bacterium residue

A technology of cephalosporins and cephalosporins, applied in the field of biomedicine, to achieve the effect of reducing emissions, reducing dosage, and realizing clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

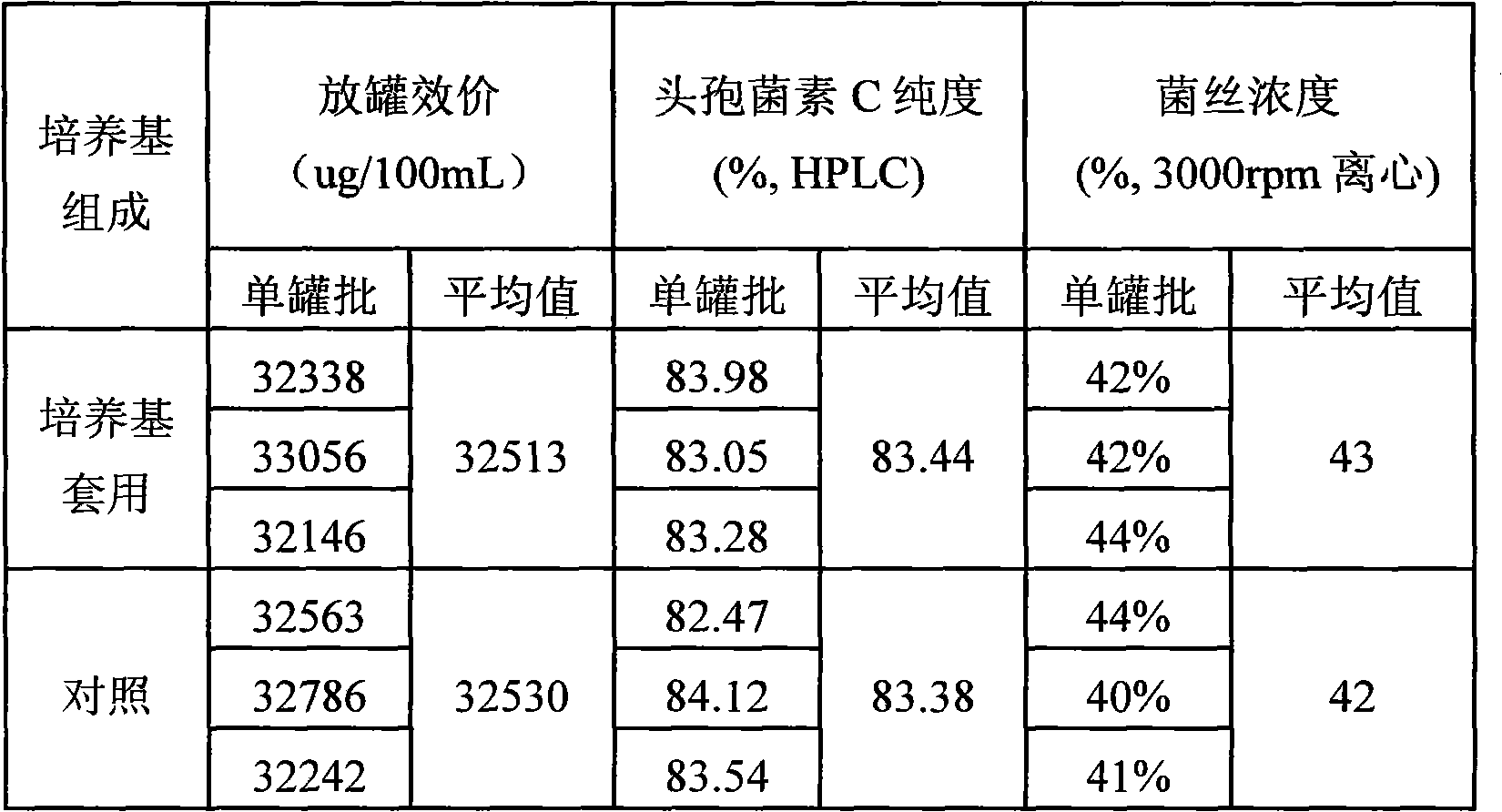

Examples

Embodiment 1

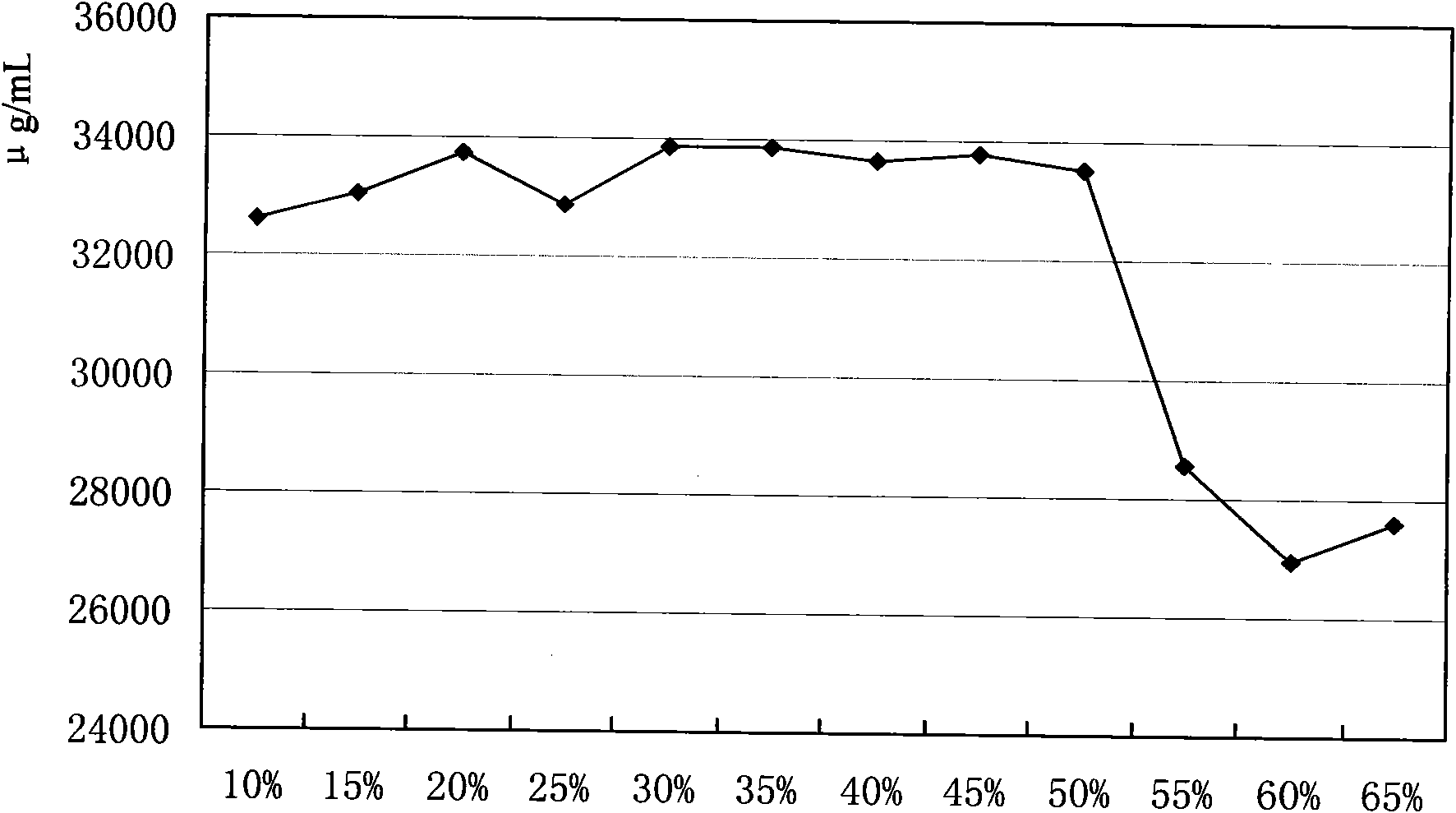

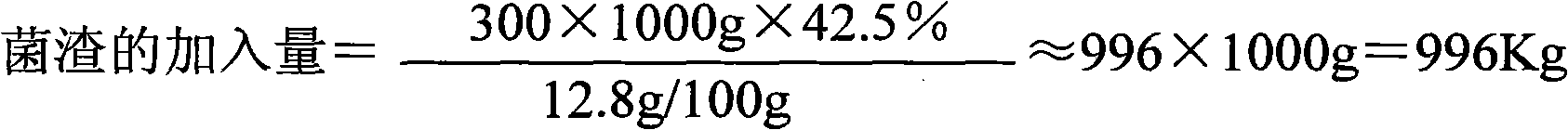

[0028] Gather 60m 3 Fermentation tank (equipment parameters: three layers of stirring paddles, six straight-blade turbine stirring paddles, d / D=0.1875, and the linear velocity of the tip of stirring paddles is 8-10m / s) Cephalosporin C fermentation broth is filtered through a filter cloth with an aperture of 30 The biochemical indexes of the bacterial residue filtered by the plate and frame filter press of ~40μm were tested. The test results were: total sugar 2.27g / 100g, protein content 12.8g / 100g;

[0029] Substitute substances are selected: mainly replace peanut cake flour with fungus residue, and substitute dextrin;

[0030] Determination of the replaced substance - the protein content of peanut flour: 42.5%;

[0031] Calculate the amount of mushroom residue added according to the protein content of peanut cake flour and mushroom residue and the substitution amount of peanut cake flour according to 300Kg of substitute peanut cake flour (the replacement ratio of peanut cake ...

Embodiment 2

[0040] Gather 60m 3 Fermentation tank (equipment parameters are the same as in Example 1) Cephalosporin C fermentation broth is filtered by the ultrafiltration membrane with a pore size of 50,000 molecular weight, and its biochemical index is detected. The detection result: total sugar 1.87g / 100mL, protein content 5.4g / 100mL;

[0041] Substitute substances are selected: mainly replace peanut cake flour with fungus residue, and substitute dextrin;

[0042] Determination of the replaced substance - the protein content of peanut flour: 42.5%;

[0043] Calculate the amount of mushroom residue added according to the protein content of peanut cake flour and mushroom residue and the substitution amount of peanut cake flour according to 260Kg of substitute peanut cake flour (the replacement ratio of peanut cake flour is 37.1%).

[0044]

[0045] Then according to the added amount of the fungus residue and the total sugar content of the fungus residue, calculate the amount of subs...

Embodiment 3

[0052] Gather 60m 3 Fermentation tank (equipment parameters are the same as in Example 1) the bacterial residue of the cephalosporin C fermentation broth filtered by the plate and frame filter press, dried to a moisture content of less than 9.5%, pulverized, passed through a 60-mesh sieve, and a sample was taken to detect its biochemical index, Test results: total sugar 32.6g / 100g, protein content 51.06g / 100g;

[0053] Substitute substances are selected: mainly replace peanut cake flour with fungus residue, and substitute dextrin;

[0054] Determination of the replaced substance - the protein content of peanut flour: 42.5%;

[0055] Calculate the amount of mushroom residue added according to the protein content of peanut cake flour and mushroom residue and the substitution amount of peanut cake flour according to 230Kg of substitute peanut cake flour (the replacement ratio of peanut cake flour is 32.8%).

[0056]

[0057] Then according to the added amount of the fungus r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com