Flux cored wire for particle reinforced aluminum-based composite material fusion welding

A particle-reinforced aluminum and flux-cored welding wire technology, applied in the direction of welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of low strength of welded joints, unfavorable in-situ reaction of the molten pool, weakening of the strengthening phase, etc., to achieve The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

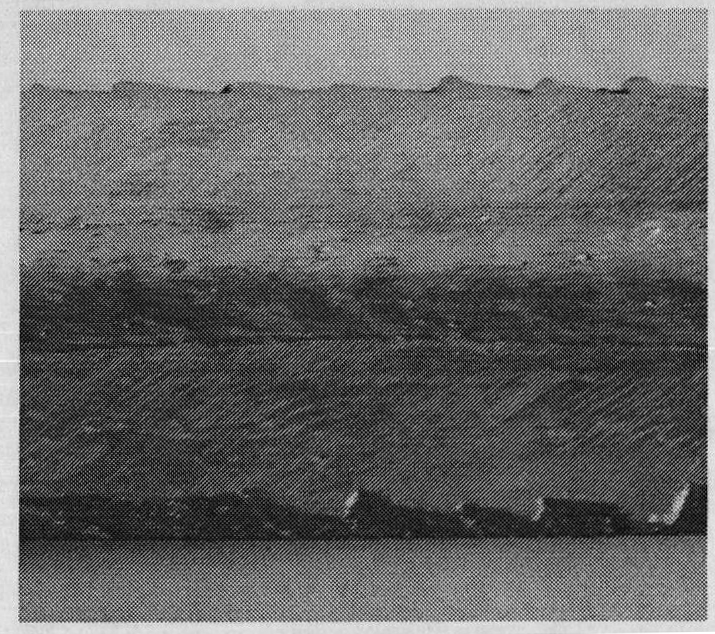

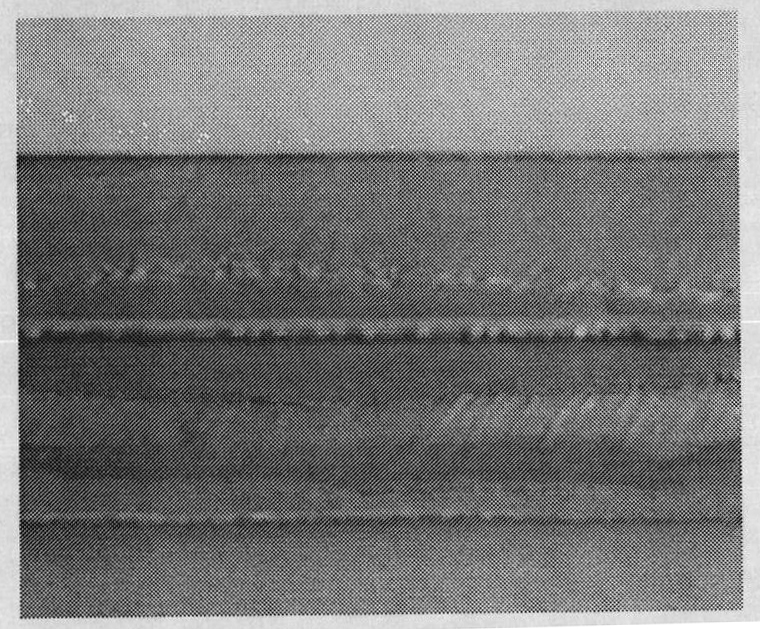

[0045] The applied flux cored wire diameter is The welding wire powder accounts for 20% of the total mass of the flux cored wire, the flux core powder is 40Ti-20Ni-Al, and the aluminum skin of the wire is 7Si-Al, and the SiCp / 6061 composite material is welded. Before welding, put the flux-cored wire into a vacuum oven, keep it warm at 200°C for three hours, take it out of the oven after the wire is cooled, and use 180 # The base metal and flux-cored wire are sanded to remove the oxide film, and then cleaned with acetone. After drying the sample at 150°C, use Ar+25%N 2 As ion gas, the ion gas flow rate is 3L / min, with Ar as the shielding gas, the shielding gas flow rate is 9L / min, the welding current is 80A, the welding speed is 60mm / min, and the flux cored wire adding speed is 40mm / min~80mm / min. Sampling and analysis of welded joints after welding, by figure 1 , figure 2 It can be seen that a macroscopically well-formed welded joint can be obtained by adding flux-cored...

Embodiment 2

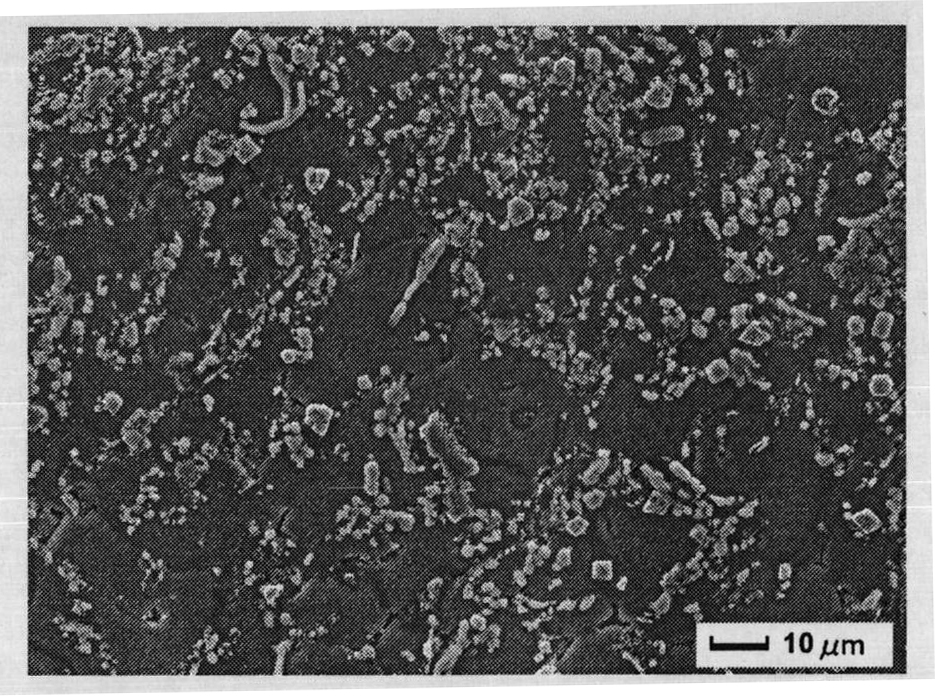

[0047] The applied flux cored wire diameter is The welding wire powder accounts for 20% of the total mass of the flux cored wire, the flux core powder is 40Ti-20Mg-Al, and the aluminum skin of the welding wire is 7Si-Al, and the SiCp / 6061 composite material is welded. Before welding, put the flux-cored wire into a vacuum oven, keep it warm at 200°C for three hours, take it out of the oven after the wire is cooled, and use 180 # The base metal and flux-cored wire are sanded to remove the oxide film, and then cleaned with acetone. After drying the sample at 150°C, use Ar+25%N 2 As ion gas, the ion gas flow rate is 3L / min, with Ar as the shielding gas, the shielding gas flow rate is 9L / min, the welding current is 80A, the welding speed is 60mm / min, and the flux cored wire adding speed is 40mm / min~80mm / min. After welding, the welded joints were sampled and analyzed, and the results showed that: TiC, TiN, AlN, Al 3 Ti, MgAl 2 o 4 and Mg 3 N and other reinforcing particles,...

Embodiment 3

[0049] The applied flux cored wire diameter is The welding wire powder accounts for 20% of the total mass of the flux cored wire, the flux core powder is 40Ti-20Mg-5La-Al, and the aluminum skin of the wire is 7Si-Al, and the SiCp / 6061 composite material is welded. Before welding, put the flux-cored wire into a vacuum oven, keep it warm at 200°C for three hours, take it out of the oven after the wire is cooled, and use 180 # The base metal and flux-cored wire are sanded to remove the oxide film, and then cleaned with acetone. After drying the sample at 150°C, use Ar+25%N 2 As ion gas, the ion gas flow rate is 3L / min, with Ar as the shielding gas, the shielding gas flow rate is 9L / min, the welding current is 80A, the welding speed is 60mm / min, and the flux cored wire adding speed is 40mm / min~80mm / min. After welding, the welded joints were sampled and analyzed, and the results showed that: TiN, TiC, Ti 5 Si 3 , AlN, AlTi, Al 3 Reinforcing particles such as Ti and SiC, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com