Nanometer powder of titanium oxide coated by zinc oxide and preparation method thereof

A nano-powder and titanium oxide technology, applied in the field of functional ceramic materials, can solve the problems of low photocatalytic efficiency and low temperature resistance, and achieve the effect of high photocatalytic efficiency and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] ① Prepare tetrabutyl titanate and urea with a molar ratio of 5:1, the volume of the tetrabutyl titanate is V1; prepare a mixed solution of glacial acetic acid and absolute ethanol with a molar ratio of 1:19, the The volume of glacial acetic acid is V2; the volume is distilled water of V3; wherein, V1: V2: V3 is 5: 1: 1.67; prepare saturated zinc nitrate solution, wherein the mol ratio of Zn2+ and tetrabutyl titanate is 0.1: 1;

[0021] 2. urea is dissolved in step 1. with dehydrated alcohol, under electromagnetic stirring, add step 1. the mixed solution of glacial acetic acid and dehydrated alcohol, be 98% concentrated nitric acid solution with mass concentration and adjust pH value to be 2, Stir for 0.5 to 1 hour; then slowly drop in V1mL of tetrabutyl titanate described in step ① under rapid stirring, and stir for 5 hours; then slowly drop in V3mL of distilled water under rapid stirring to obtain solution A;

[0022] ③ Stir the solution A obtained in step ② at room te...

Embodiment 2 Embodiment 3

[0028] The difference from Example 1 is that the holding temperatures in step ⑤ are 900°C and 950°C respectively.

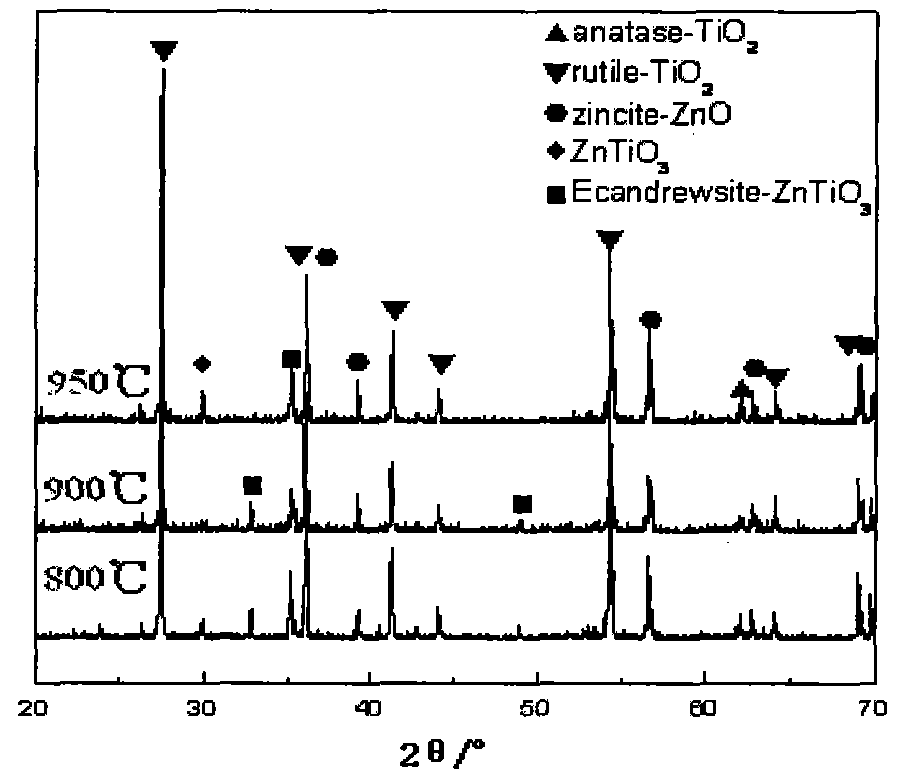

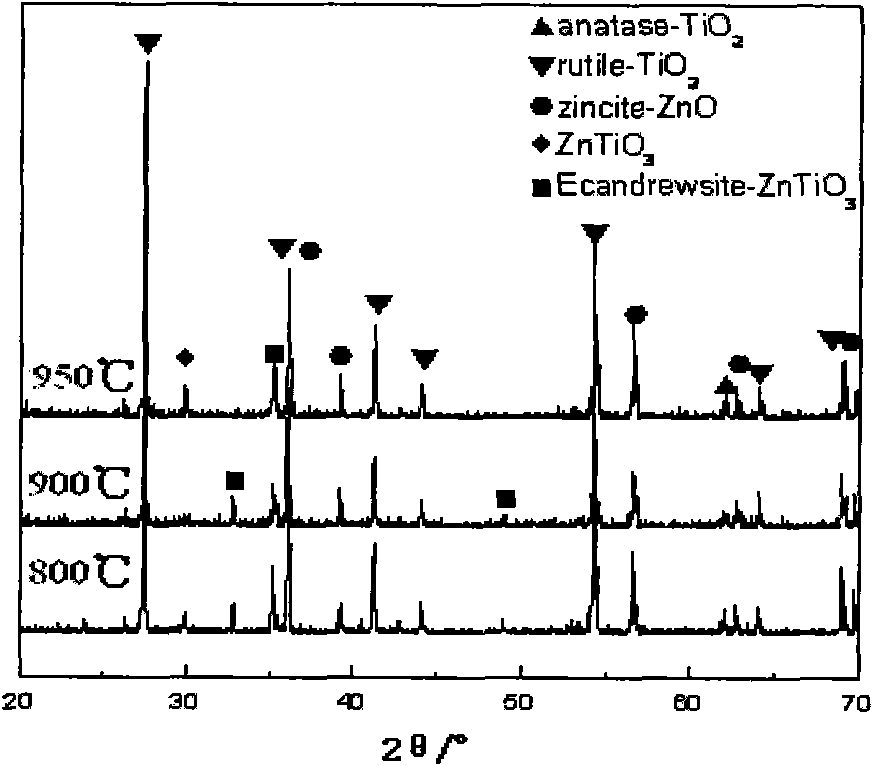

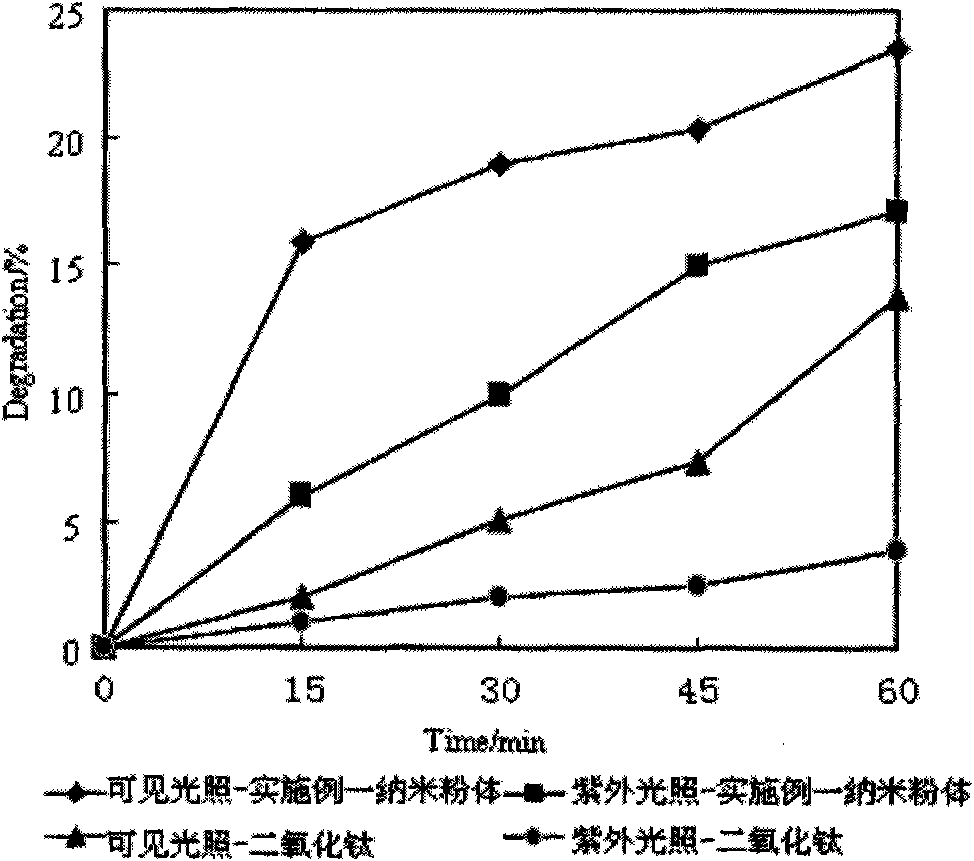

[0029] The nano-powders prepared in Examples 1 to 3 were analyzed by XRD respectively, and the XRD patterns can be found in figure 1 . It can be seen from the figure that the nanopowder prepared by the present invention still has a mixed crystal structure of anatase phase and rutile phase after being calcined at 950° C., and the crystal particle size is about 75 nm. However, the titanium oxide powder prepared by the general method will rapidly transform from anatase-type titanium oxide to rutile-type titanium oxide at 550-700°C. It can be seen that the zinc oxide-coated titanium oxide nano-powder prepared by the present invention increases the crystal transformation temperature by 200° C., and significantly improves the high temperature resistance.

[0030] In addition, obvious zinc titanate (ZnTiO 3 ) peak, indicating the presence of a transition layer. Beca...

Embodiment 4

[0032] ① Prepare tetrabutyl titanate and urea with a molar ratio of 2.5:1, the volume of the tetrabutyl titanate is V1; prepare a mixed solution of glacial acetic acid and absolute ethanol with a molar ratio of 1:10, the The volume of glacial acetic acid is V2; the volume is distilled water of V3; wherein, V1: V2: V3 is 2.5: 1: 2; prepare saturated zinc sulfate solution, wherein the mol ratio of Zn2+ and tetrabutyl titanate is 0.15: 1;

[0033] ②Dissolve the urea with absolute ethanol, add a mixed solution of glacial acetic acid and absolute ethanol under stirring, adjust the pH value to 2 with a concentrated nitric acid solution with a mass concentration of 98%, and stir for 0.5 to 1 h; then stir rapidly slowly drop into the tetrabutyl titanate, and stir for 1 h; then slowly drop into the distilled water under rapid stirring to obtain solution A;

[0034] ③ Stir the solution A obtained in step ② at room temperature for 5 hours to form a transparent gel, and seal it for 7 days...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com