Method for continuously producing pinane by pinene and device therefor

A production method and technology of pinene are applied in the field of continuous production of pinene to prepare pinane and its device field, which can solve the problem that automation control is difficult, the cis-trans ratio of pinane is difficult to control, only one month, and the longest is no more than 1 month. About 3 months and other problems, to achieve the effect of convenient large-scale production and scale-up, high cis-pinane selectivity, and improvement of human operation deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

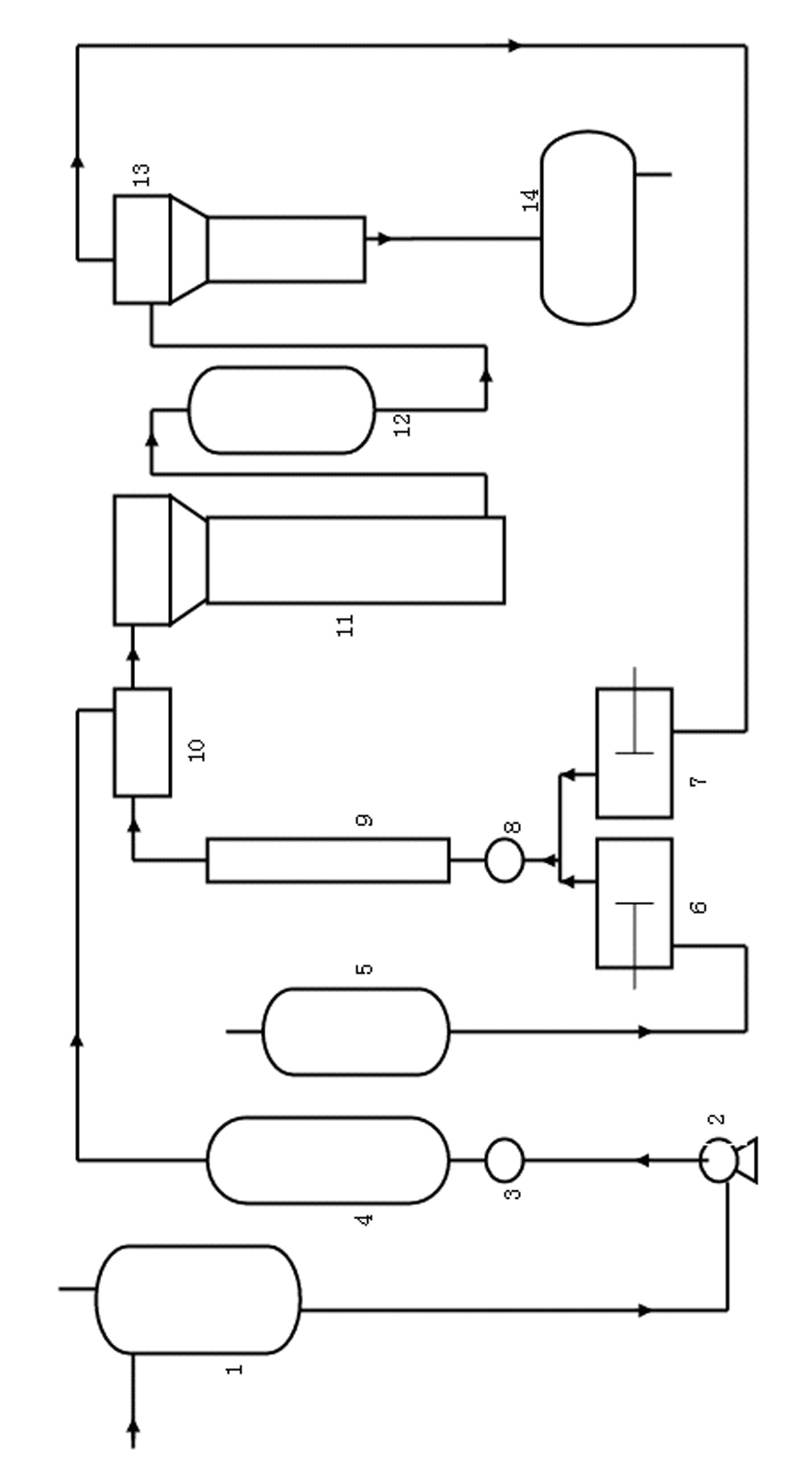

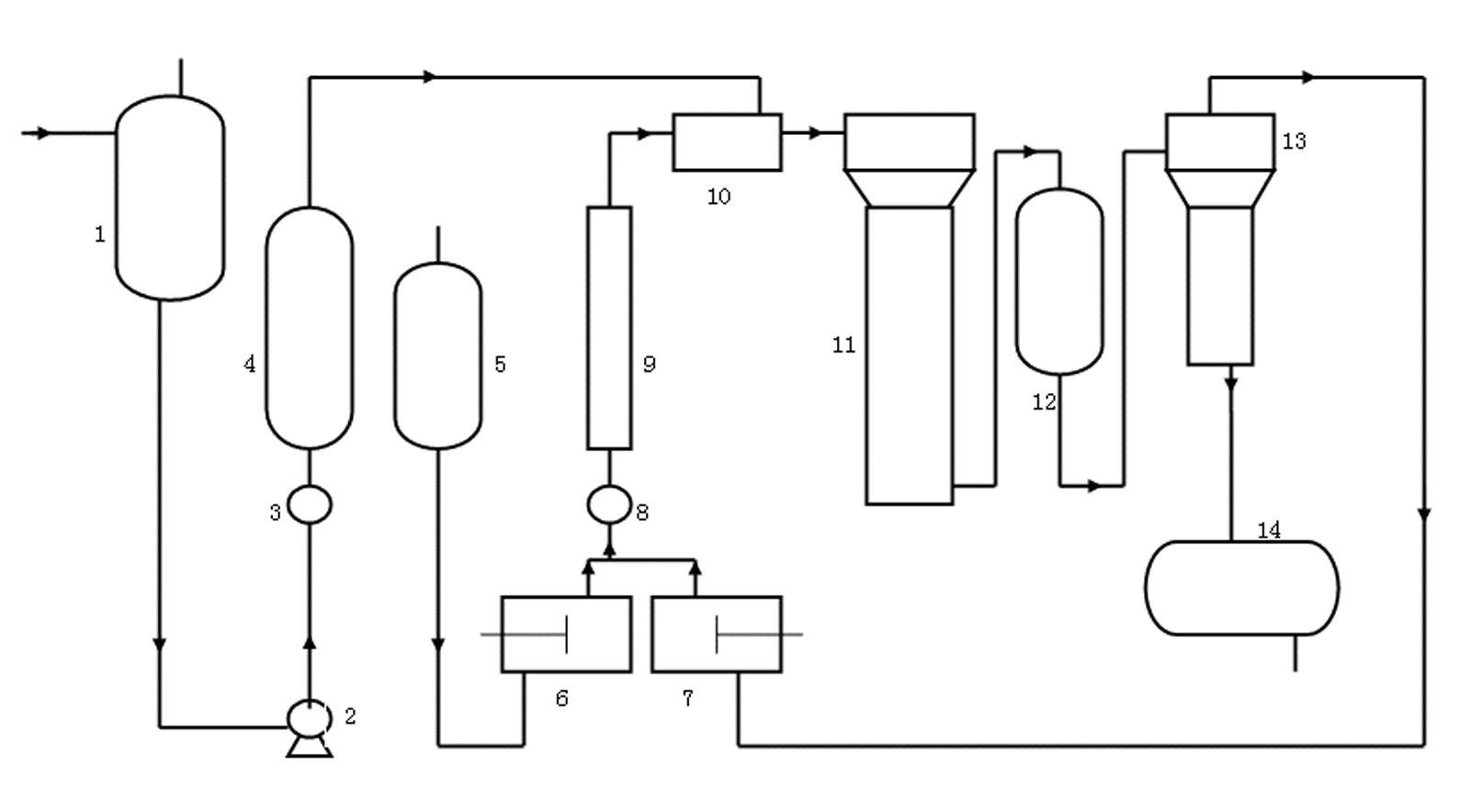

[0029] Example 1 Example of a continuous production device for preparing pinane from pinene of the present invention

[0030] refer to figure 1, Pinene of the present invention prepares the continuous production device embodiment of pinane by raw material storage tank 1, feeding pump 2, flowmeter I 3, liquid preheater 4, hydrogen storage tank 5, hydrogen compressor 6, hydrogen circulation compressor 7. Flow meter II 8, hydrogen preheater 9, gas-liquid mixer 10, fixed bed reactor 11, cooler 12, gas-liquid separator 13, product storage tank 14; raw material storage tank 1 outlet and feeding pump 2 inlet The outlet of feeding pump 2 is connected with the inlet of flowmeter Ⅰ 3, the outlet of flowmeter Ⅰ3 is connected with the inlet of liquid preheater 4, the outlet of liquid preheater 4 is connected with the inlet of gas-liquid mixer 10, the outlet of hydrogen storage tank 5 is connected with hydrogen compression The machine 6 is connected, the outlet of the hydrogen compressor ...

Embodiment 2

[0032] Embodiment 2 prepares the continuous production method operation step embodiment of p-pinane by pinene

[0033] (1) First put 200kg~1000kg of catalyst into the fixed bed reactor 11, and replace the air with nitrogen; open the heating jacket of the fixed bed reactor 11, and preheat the fixed bed reactor 11 to 120°C~300°C; turn on the hydrogen Compressor 6, at 800 m 3 / h ~1000m 3 The hydrogen flow rate per hour (standard state meter) is sent to the hydrogen preheater 9, the hydrogen is preheated to 50 ° C ~ 260 ° C, and the feeding pump 2 is turned on at the same time, and the raw pinene stored in the raw material storage tank 1 is 0.1 m 3 / h ~0.5m 3 The flow rate of / h is sent to the liquid preheater 4, the pinene is preheated to 80 ℃ ~ 290 ℃, then the preheated hydrogen and pinene are placed in the gas-liquid mixer 10, and the gas-liquid volume ratio is controlled to be 1600~10000, after mixing evenly, enter the fixed bed reactor 11, and complete the hydrogenation r...

Embodiment 3~6

[0040] The hydrogenation reaction temperature is controlled at 50°C, the amount of catalyst added is set at 200kg, 500kg, 800kg, and 1000kg respectively, the hydrogen preheating temperature is 40°C~50°C, and the pinene preheating temperature is 40°C~50°C; the gas-liquid volume ratio is 1600, 5000, 7000, 9000, 10000, the hydrogenation reaction pressure is 10 Mpa, 13 Mpa, 16 Mpa, 20 Mpa. When the reaction conditions were stable, the pinane content in the hydrogenation products was sampled and analyzed to be 90.5%, 93.1%, 96.2%, and 98%, respectively, and the conversion rates of pinene to pinane by hydrogenation reached 98.1%, 99.2%, 99.5%, and 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com