Biodegradable polypropylene carbonate composite material and preparation method thereof

A polypropylene carbonate and composite material technology is applied in the field of polypropylene carbonate composite film material and its preparation, and achieves the effects of good physical and chemical properties, heat resistance and dimensional stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

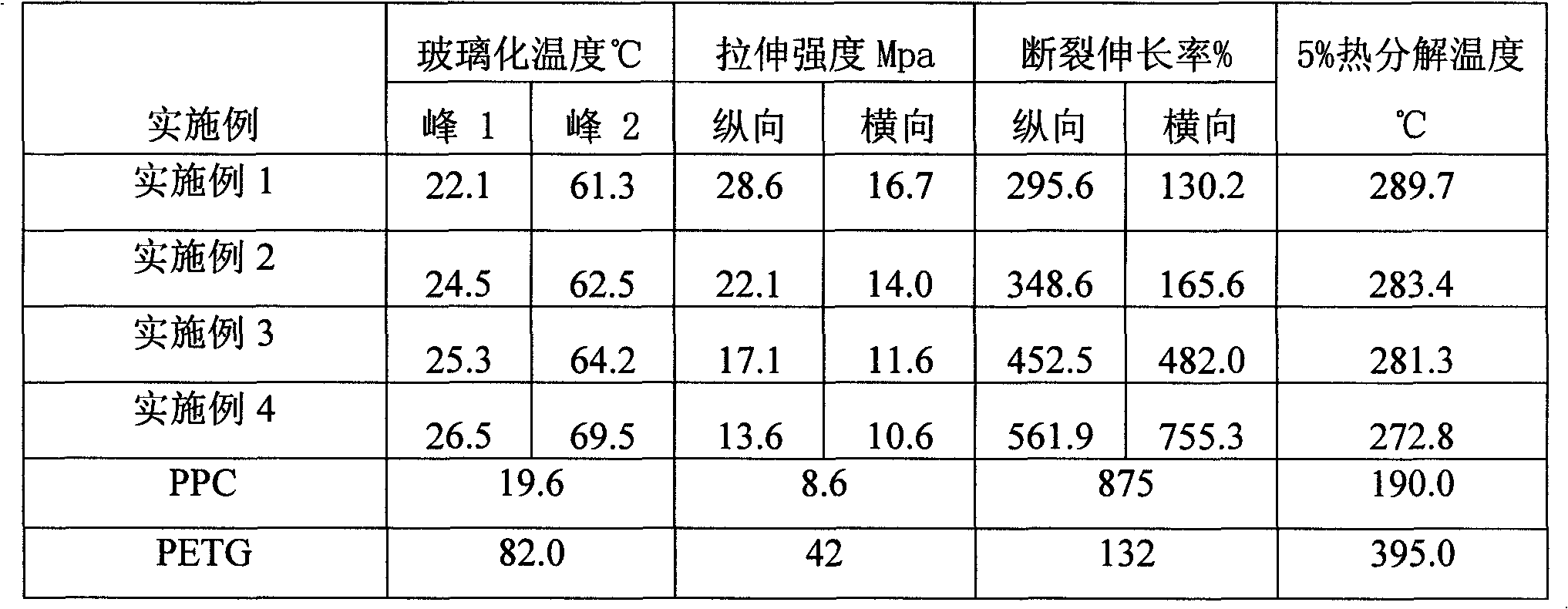

Embodiment 1

[0025] Embodiment 1, preparation PPC / PETG composite film

[0026] Weigh each component by the following parts by mass:

[0027] PPC60

[0028] PETG 40

[0029] Silica (heat-resistant stabilizer) 1

[0030] Triphenyl phosphite (antioxidant) 0.5

[0031] Stearamide (lubricant) 0.3

[0032] Benzoalkyl ether (photodecomposition agent) 0.2

[0033] Erucamide (anti-sticking agent) 1

[0034] Oxalic acid (biodegradation accelerator) 0.5

[0035] The preparation process is as follows:

[0036] The above raw materials were dried in a vacuum oven at 45°C for 5 hours, then mixed in a high-speed mixer at a speed of 25000r / min for 0.5-1 minute, and then entered into a twin-screw extruder at a temperature of 160°C for extrusion and granulation. The specific process is as follows: the mixed raw materials are discharged from the hopper, the pellets are extruded from the first zone to the die head to be extruded upward, and then blown into a cylindrical film bubble by air compression, ...

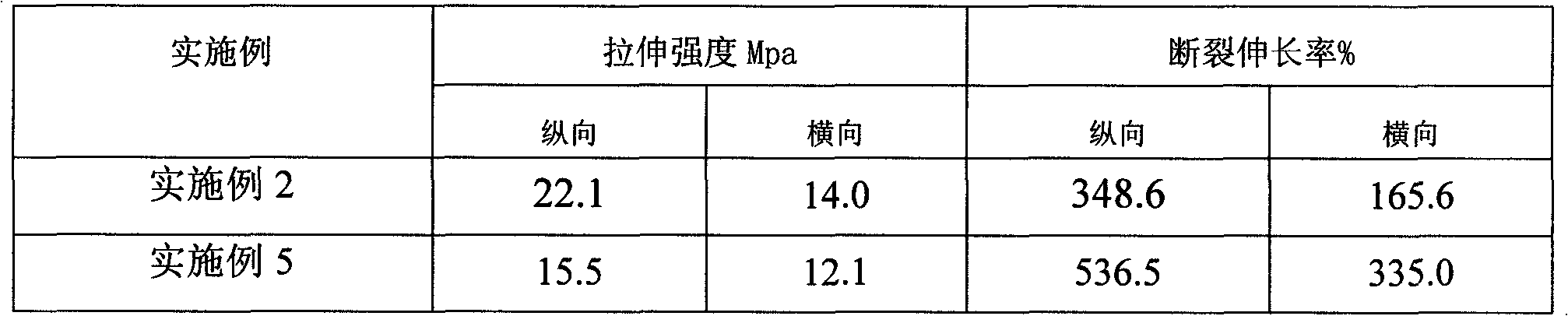

Embodiment 2

[0047] Embodiment 2, preparation PPC / PETG composite film

[0048] Weigh each component according to the following parts by mass:

[0049] PPC 70

[0050] PETG 30

[0051] Montmorillonite (heat-resistant stabilizer) 1

[0052] Bisphenol A (antioxidant) 0.5

[0053] Zinc stearate (lubricant) 0.3

[0054] Benzophenone (photodecomposition agent) 0.2

[0055] Silica (anti-dusting agent) 2

[0056] Citric acid (biodegradation accelerator) 0.5

[0057] The preparation process is as follows:

[0058] The above raw materials were dried in a vacuum oven at 45°C for 5 hours, then mixed in a high-speed mixer at a speed of 15000r / min for 0.5-1 minute, and then entered into a twin-screw extruder at a temperature of 160°C for extrusion and granulation. The specific process is as follows: the mixed raw materials are discharged from the hopper, the pellets are extruded from the first zone to the die head to be extruded upward, and then blown into a cylindrical film bubble by air compre...

Embodiment 3

[0068] Embodiment 3, preparation PPC / PETG composite film

[0069] Weigh each component according to the following parts by mass:

[0070] PPC 80

[0071] PETG20

[0072] Zinc oxide (heat-resistant stabilizer) 1

[0073] Bisphenol A (antioxidant) 0.5

[0074] Zinc stearate (lubricant) 0.3

[0075] Benzophenone (photodecomposition agent) 0.2

[0076] Silica (anti-dusting agent) 2

[0077] Citric acid (biodegradation accelerator) 0.5

[0078] The preparation process is as follows:

[0079] The above raw materials were dried in a vacuum oven at 45°C for 5 hours, then mixed in a high-speed mixer at a speed of 25000r / min for 0.5-1 minute, and then entered into a twin-screw extruder at a temperature of 160°C for extrusion and granulation. The specific process is as follows: the mixed raw materials are discharged from the hopper, the pellets are extruded from the first zone to the die head to be extruded upward, and then blown into a cylindrical film bubble by air compression,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com