Monocrystalline silicon piece texturizing liquid and texturizing method thereof

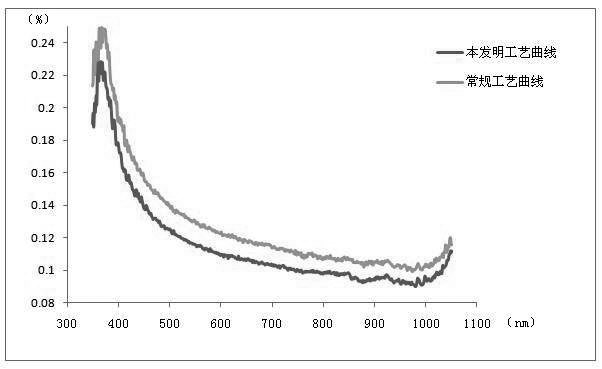

A single crystal silicon wafer and texturing liquid technology, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems that are not conducive to the deep and uniform contact of the diffusion junction in the rear channel, high fragmentation rate of the cell, and manufacturing problems. Instable fleece effect and other problems, to achieve the effect of small thinning, clear spire and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: A kind of monocrystalline silicon wafer texturing liquid

[0024] In parts by mass, sodium hydroxide is 0.6%, isopropanol is 4.5%, additives are 0.4%, and water is 94.5%. The proportion of additives is in parts by mass, glucose 0.5%, nonylphenol polyoxyethylene ether 1500ppb, sodium lactate 0.5%, propylene glycol 0.1%, sodium silicate 0.2%, sodium carbonate 0.2%, and the rest is water.

Embodiment 2

[0025] Embodiment 2: another monocrystalline silicon wafer texturing liquid

[0026] In parts by mass, sodium hydroxide is 0.5%, isopropanol is 8%, additives are 0.1%, and water is 94.5%. The proportion of additives is in parts by mass, glucose 2%, decylphenol polyoxyethylene ether 6000ppb, sodium citrate 0.1%, propylene glycol 0.05%, sodium silicate 0.1%, sodium carbonate 0.05%, and the rest is water.

Embodiment 3

[0027] Example 3: Yet another texturing solution for monocrystalline silicon wafers

[0028] In parts by mass, sodium hydroxide is 1.5%, isopropanol is 4%, additives are 1.2%, and water is 94.5%. The proportion of additives is in parts by mass, potassium gluconate 0.1%, nonylphenol polyoxyethylene ether 800ppb, sodium lactate 1.5%, propylene glycol 1.2%, sodium silicate 4%, sodium bicarbonate 1%, and the rest is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com